Easy To Install Box Profile Roofing

Order A Sample!

The best way to choose a coating and colour for your box profile sheets is by ordering a sample pack.

Order A Sample Pack

High Quality Steel

The coated steel strips we make into our box profile sheets are produced in accordance with a strict series of quality standards by leading suppliers, giving us traceability and quality control. All our corrugated and box profile sheets have been independently tested to current CE EN 14782 requirements for your peace of mind.

Durable Coatings

As a roofing sheet material, steel has long been used and has the added benefit of being recyclable. To produce our pre-coated sheets, a system of multi-layer coatings is applied to the zinc-coated high tensile steel strip and then oven-cured to ensure optimum adhesion. This gives box profile sheets with excellent corrosion resistance and climatic protection together with abrasion resistance and a strong structure.

Advantages of Cladco Box Profile Sheets

- Hardwearing and corrosion resistant

- Sheets can be cut to custom lengths

- Lightweight for easy handling and installation

- Multiple rigid profiles across the sheets provide high tensile strength

- Excellent rainwater run off preventing build up of leaves and debris

- Appropriate for low pitch roofs down to 4 degrees.

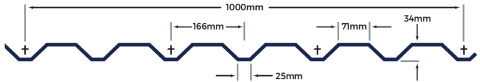

- Sheets provide 1m coverage when lapped - greater than alternative brands

Typical Uses

- Agricultural barns and structures

- Storage facilities

- Lean-to covers

- Storage sheds

- Garden sheds

- Garages

- Industrial units

- Contemporary new build renovations

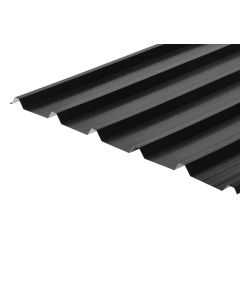

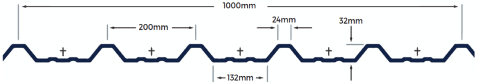

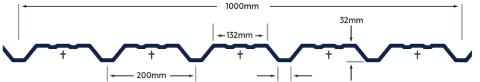

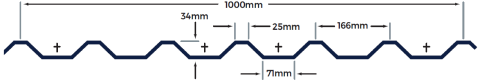

Profile Diagrams

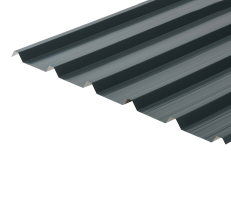

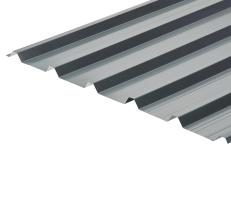

32/1000 Box Profile

34/1000 Box Profile

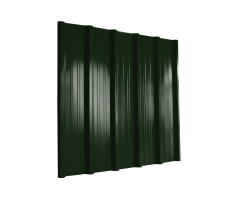

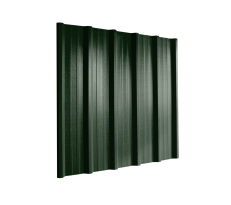

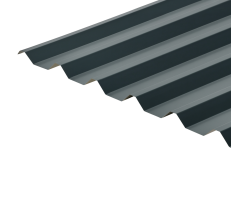

Coating Options

PVC Plastisol

PVC plastisol is a 200-micron thick coating of high-quality PVC, with an embossed leather grain finish. The coating is applied to the steel roofing sheets during the manufacturing process.

The outcome of this improves the strength and longevity of the sheet, and adds a lifespan of typically 15-25 years to the first maintenance or repaint, with a life in excess of 40 years in normal environments. PVC plastisol also improves the sheet's resistance to scratching, weathering and any external damage.

PVC plastisol produces a sheet with excellent climatic and UV protection, together with abrasion resistance and high strength. Cladco provides a comprehensive choice of eleven colours, allowing building aesthetics to be matched to the surrounding environment. These colours include: Anthracite, Black, Chestnut, Goosewing Grey, Slate Blue, Vandyke Brown, Merlin Grey, Juniper Green, Moorland Green, Olive Green, and White.

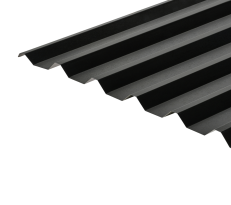

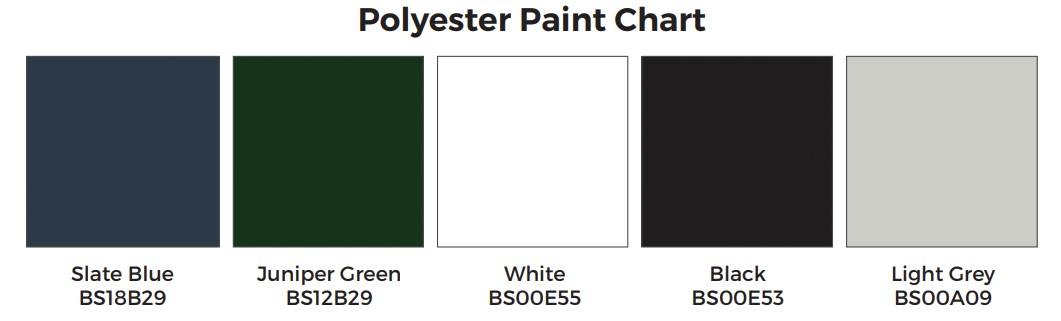

Polyester Paint

Polyester paint metal sheeting is manufactured from a 25-micron thick, smooth enamel-coated steel sheet, which is economic to use and gives excellent weather resistance and longevity of typically 8 to 12 years to the first maintenance or repaint, with a life in excess of 20 years in normal environments. We provide a choice of five colours in our polyester coatings to suit your design needs, allowing you to be sympathetic to the surrounding environment with your colour choice. These colours include: Slate Blue, Juniper Green, White, Black and Light Grey.

The reverse/internal surface of the polyester box profile roofing sheets is coated with a standard alkali grey wash coat.

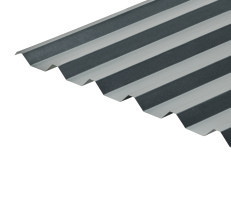

Galvanised

The coated steel strip we form into roofing sheet profiles and flashings is produced by leading suppliers, giving us quality control and traceability of the material we use. To produce high-quality, pre-coated sheeting, a system of multi-layered coatings is applied to a zinc-coated, high-tensile steel strip and oven-cured to ensure optimum adhesion.

For further information on coatings, take a look at our coatings information page.

Dripstop Anti-Condensation

What is dripstop? Dripstop is an anti-condensation adhesive felt membrane that is applied to all our box profile roofing sheets during the manufacturing process. Dripstop condensation control is a proven solution to preventing drips from forming on the underside of your roofing sheets, especially in conditions of high humidity and lack of airflow.

Installing Your Box Profile Sheets

For a single-pitch box profile roof, the minimum pitch we recommend is 4-5 degrees. Lay your box profile sheets in runs. Make a start at the eaves and in the corner away from the direction of the prevailing wind to prevent water ingress and side laps facing into the wind. Adjustments will have to be made regularly if the first sheet is not laid perpendicular to the eaves and ridge - something that may be unavoidable if the building is not square.

For more information and further installation help and advice, take a look at our 32/1000 installation guide and 34/1000 installation guide, or visit our roofing help and advice page.

Box Profile Roof Lights

Cladco 34/1000 and 32/1000 GRP roof lights are manufactured from heavy-duty 1.5mm thick translucent GRP (Glass Reinforced Plastic) materials and will let in daylight through at a transmission rate of over 80%.

Their width and profile match that of our box profile metal roof sheets, ensuring these translucent roof light panels can be installed seamlessly alongside our box profile roof sheets. GRP translucent roof lights are available in lengths of 2.5m, 3m and 3.5m.

Insulated Box Profile Panels

32/1000 box profile insulated panels are perfect for cladding both walls and roofs. Insulated panels are sold in set lengths from 2.5m up to 6m, providing an off-the-shelf insulated roof panel that’s easy to fix seamlessly with our 23/1000 box profile sheets and help to prevent condensation.

FAQs

How many sheets do i need?

When it comes to planning a box profile roofing project, our handy roofing sheet calculator will guide you through how many sheets to order, as well as what potential flashings and accessories you may need, and will provide the total cost of your upcoming project.

How much do you overlap box profile sheets?

Sheets should be overlapped by a minimum of 1 profile per sheet.

What is the width of your box profile sheets?

Both the 32/1000 and the 34/1000 box profile sheets are 1000mm in width when lapped.

What coating is best for my box profile project?

Typically, polyester paint and PVC plastisol coatings are popular choices. Polyester coatings offer good durability and cost-effectiveness, while PVC plastisol provides enhanced durability and resistance to weathering. Assessing factors like weather exposure, aesthetic preferences, and budget will help determine the ideal coating for your project.

Which thickness of box profile is best for my project?

The suitable thickness of our box profile roofing sheets for your project depends on factors like structural and durability requirements. Thicker sheets offer increased strength and durability, ideal for demanding environments or larger structures. For standard residential or commercial applications, 0.5mm to 0.7mm thickness often suffices. Assessing your specific project's load-bearing needs and environmental conditions will help determine the most suitable thickness for optimal performance.