Dripstop Information

At Cladco Profiles, we strive to ensure that every item works for you, for as long as possible. One way of prolonging the life of your metal roofing, would be to install them with Dripstop®, an additional layer applied to the underside of the sheet to help minimise moisture build-up.

The term ‘roof sweating’ refers to condensation that can occur in uninsulated buildings when excess humidity collects on the reverse of your roof. It typically happens at the start and end of the day due to the sharp differences in temperature inside and outside your roofing system. Water vapour can collect and form droplets, which may fall and cause rot, rust, or damage to flooring.

The Dripstop® layer can be added to 32/1000 box profile, 34/1000 box profile, 13/3 corrugated and 41/1000 tile form sheets in our 0.7mm roofing range. We do not manufacture Dripstop® on our 0.5mm sheets. To ensure optimum performance, it is recommended that roofs are pitched to more than 10°. Please get in touch with our sales team on 01837 659901 to enquire about using Dripstop® in your project.

What is Dripstop®?

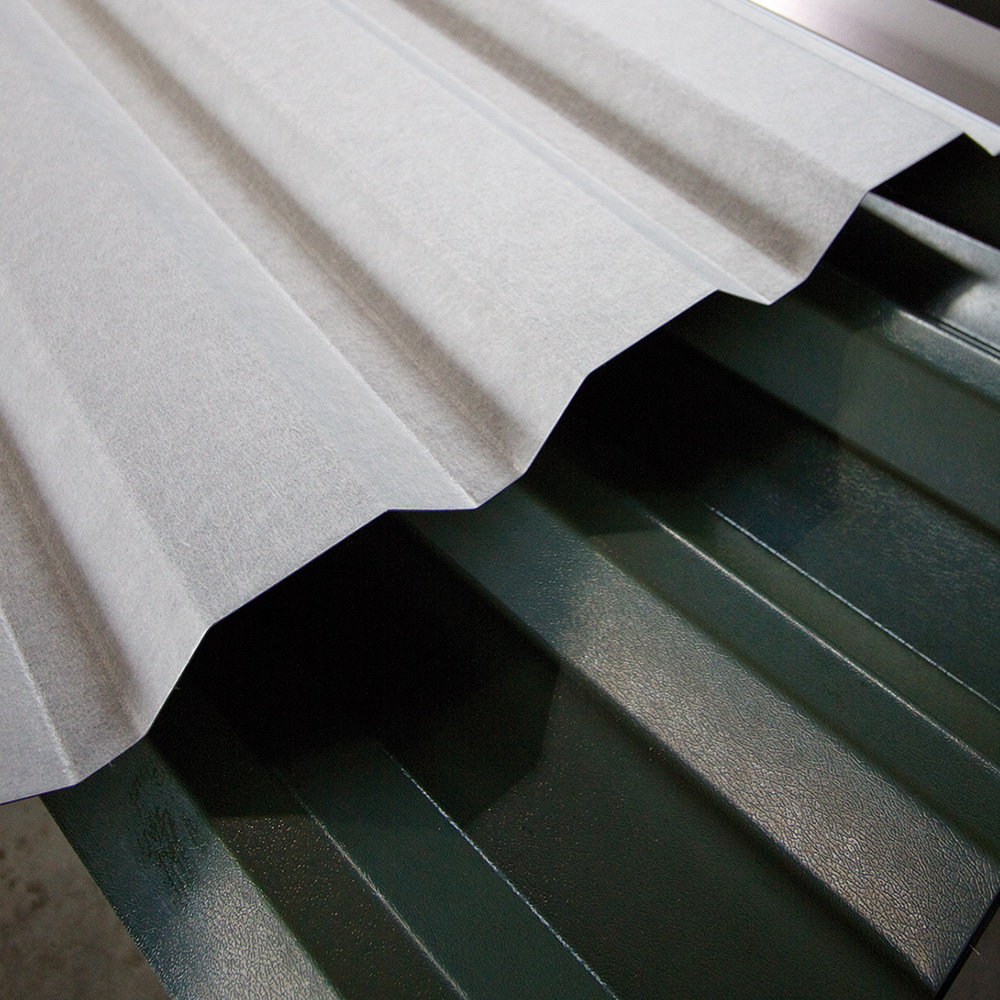

Dripstop® is an anti-condensation, grey polyester fleece membrane which is applied to the reverse side of sheet profiles to prevent dripping in conditions of high humidity.

The innovative technology traps moisture within specially designed pockets formed inside the membrane. These pockets hold any liquid until it can be released back into the environment within your building as normal humidity.

It’s important not to expose the Dripstop® side of the roof to sunlight, strong wind, or rain to prevent damage. You can find more information in our blog.

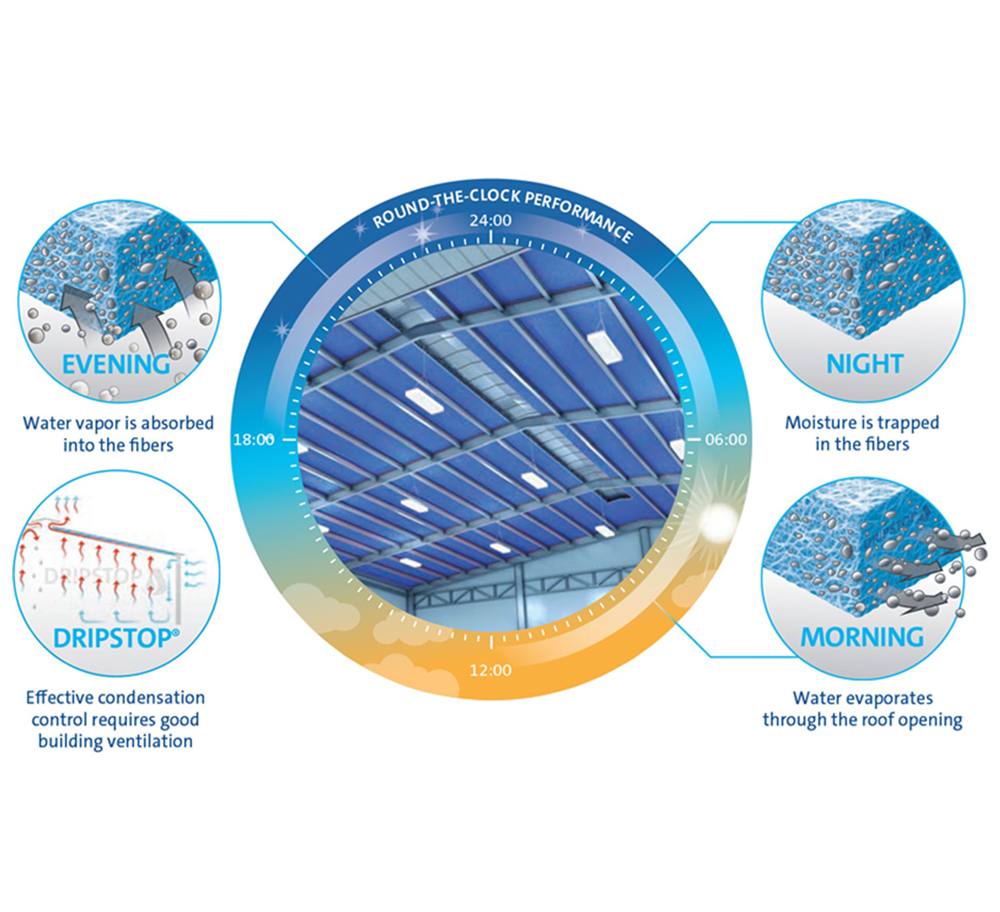

How does Dripstop® work?

Condensation forms when there are large changes in temperature, often during the transition from day to night. Dripstop® helps keep condensation safely under control by collecting vapour in small pockets within the membrane — essentially soaking it up like a towel. As the surrounding air warms up again, the collected water evaporates and the fleece membrane dries out.

While it can trap condensation, it cannot completely stop it from occurring. For the Dripstop® to work effectively, your building must have adequate ventilation to allow the membrane to dry as part of its natural cycle. This ensures the material can absorb and release large amounts of condensation without chemical agents, maximising the effectiveness and lifespan of your roof.

This cost-effective solution also helps to maintain structural integrity by providing an extra protective layer within your roofing system. Dripstop® is easy to clean using a hose or pressure washer and is incredibly durable, withstanding environmental temperatures from -40C to +80C.

Dripstop® - safe, reliable, drip-control

Condensation forms when there are large differences in temperature, often during the transition from day to night. Dripstop® keeps condensation safely under control. High air permeability ensures water evaporates completely with rising daytime temperatures and optimal roof ventilation.

The way Dripstop® works is smart and simple. The secret lies in the innovative membrane structure, which maximizes its ability to absorb and release large amounts of condensation.

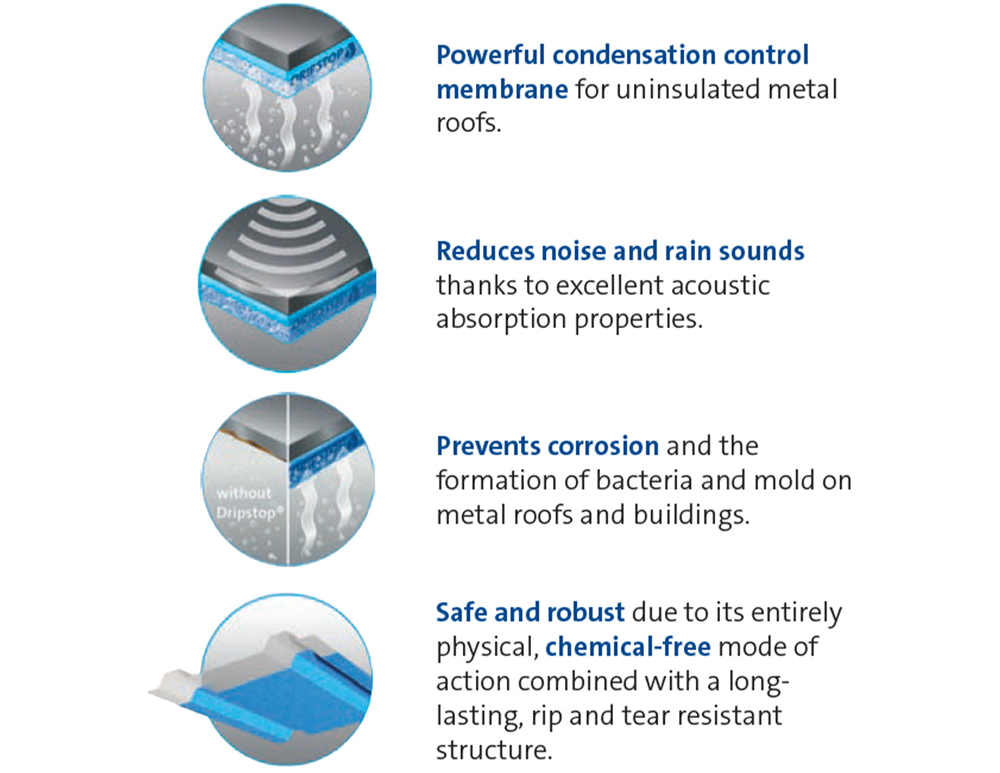

The material’s smart behaviour is based on a purely physical principle, which means it works 100% without chemical agents. That’s how Dripstop® retains its full effectiveness over the product’s entire useful life.

Where Can Dripstop® Be Used?

Dripstop® is suitable for a wide range of building types and industries where moisture control is essential, including residential, commercial, industrial, and agricultural settings.

Residential

This membrane can be installed on metal roofing sheets to protect roofing systems, lofts, and attics from condensation and water damage.

Commercial

It can help maintain dry interiors in offices, retail spaces, and warehouses by preventing moisture from dripping onto furniture, equipment, or stock.

Industrial

The membrane helps safeguard machinery, work areas, and sensitive environments such as food processing or pharmaceutical facilities from condensation-related moisture.

Agricultural

The added layer keeps barns, poultry houses, and storage sheds dry, protecting livestock, crops, and stored materials from water damage.

Dripstop® and Cladco

If you select Dripstop® on your order, it will be applied during the roll forming process on site at Cladco. This factory-fitting process ensures that by the time your sheets reach you, they’re ready to install.

If you’re unsure whether or not Dripstop® can be applied to your desired roofing sheets, please contact us - we’re happy to help.

Dripstop® Benefits

Dripstop® offers a wide range of practical benefits, making it a trusted choice for building projects across multiple industries.

Condensation control

- Protects stored goods

- Prevents harm to human health and livestock

- Helps fight corrosion

- Prevents mould and damage to the building structures

Simple installation

- Easy to install and minimizes construction time

- Cuts installation costs and time

- Reduces risk of injury during installation

Reliable quality

- Easy to clean if needed

- Reduces noise and rain sounds

- Manufacturer warranty

- Certified worldwide

Technical Information

| PROPERTY | VALUE | TESTING METHOD | |

|---|---|---|---|

| Weight | g/m2 | 110 ±10% | EN ISO 9073-1 |

| Thickness | mm | <1 | EN ISO 9073-2 |

| Water absorption 0° | g/m2 | 1000*1 min | FILC int. 19 |

| Water absorption 45° | g/m2 | 800*1 min | FILC int. 19 |

| Water absorption 90° | g/m2 | 600*1 min | FILC int. 19 |

| Water absorption | g/100cm2 | 11,44*1 0° 10,42*1 45° 9,48*1 90° |

DIN 53923 |

| Water absorption | g/m2 | 750*1 min | NF P 15-203-1 |

| Flammability | A2 - s1, d0*1 | EN 13501-1 | |

| Peel adhesion MD | N/25 mm | 10*1 min | FILC int. 29 |

| Adhesion after ageing - MD | N/25 mm | improved | Filc int.22 |

| Sound absorption in Alpha cabin; absorption coefficient | 0,02*1 500Hz 0,03*1 1000Hz 0,07*1 2000Hz 0,22*1 4000Hz 0,32*1 8000Hz |

D49 1977 | |

| Rainfall noise sound insulation | dB | 71*2 LIA 69*3 2 ΔLIA |

ISO 140-18 |

| Thermal conductivity (λ) | W/mK | 0,038 | DIN 52612 |

| Bacteria resistance | 0 | DIN EN 14119 | |

| Colour | grey | ||

| Width | mm | 1500 max | |

| Ø Card pipe | mm | 76 | |

| *1 - Nonwoven on flat metal sheet *2 - Profiled metal sheet *3 - Nonwoven on profiled metal sheet |

|||

Average values, subject to normal production tolerances.

Working Conditions

- Dripstop and metal sheet must be conditioned to an operating temperature of +10 °C or higher. It is best if they are both stored in the area where profiling takes place.

- There must be no traces of water, condensation, dust, oil or lubricants, silicone, rust… on the metal sheet surface, as impurities prevent good contact between the glue and the metal sheet and thus adversely affect the profiling process itself and the product quality.

- Surfaces containing plasticizers (e.g. Plastisol) are also not suitable for gluing. Dripstop can be applied to metal sheet with a surface tension of min. 38 mN/m. A test should be performed with a 38 mN/m test marker.

- Even pressure must be ensured over the entire surface between the metal sheet and Dripstop before profiling.

- Coverings with Dripstop must be installed in accordance with applicable building standards and good construction practices.

- Adequate constant ventilation of the roof covering must be ensured in order for Dripstop to dry. This means that the air enters at the gutter and exits through the ridge, thus ensuring a constant flow of air under the roof covering.

- The slope of the gutter must allow constant water drainage.

- In roofs with a slope of less than 10°, it is mandatory to prevent capillary action at the gutter, on the overlaps and in the ridge. A drip edge must be made at the gutter and on the ridge. In slopes exceeding 10°, it is sufficient to prevent capillary action at the gutter and on the overlaps.

Storage

The storage area must be dry and closed, and the product must not be exposed to direct sunlight. The quality of the product will not change over a period of one year from production when stored at temperatures of +5 °C ~ +30 °C.

Warning

- The product is permanently glued and cannot be re-glued once it is removed.

- Do not expose roofing sides with Dripstop to direct sunlight and other weather conditions (strong wind, rain).

- In case of contamination of Dripstop, cleaning with water is recommended.

- When installing the roof, Dripstop on the roof profiles must be dry.

- Changes in quality resulting from contamination by microorganisms are not subject to complaints.

Other

- Profiled metal sheet with Dripstop is usable at temperatures from -40 °C to 80 °C. Please contact Filc d.o.o. for further information.

- The values given here are average values and are based on existing technical expertise and experience. It is up to the user to test and verify the suitability of the product for its final use. Checking patent rights and existing legal regulations is the responsibility of the buyer. In accordance with continuous product improvement, changes in technical characteristics may occur without prior notice.

- The technical sheet is not a substitute for the technical specifications of the product. To determine the required technical parameters, please contact Filc d.o.o.