Cladco Environmental

FSC® | ISO | Recycling | Renewable Energy | Environmental Policy | Products | Blogs

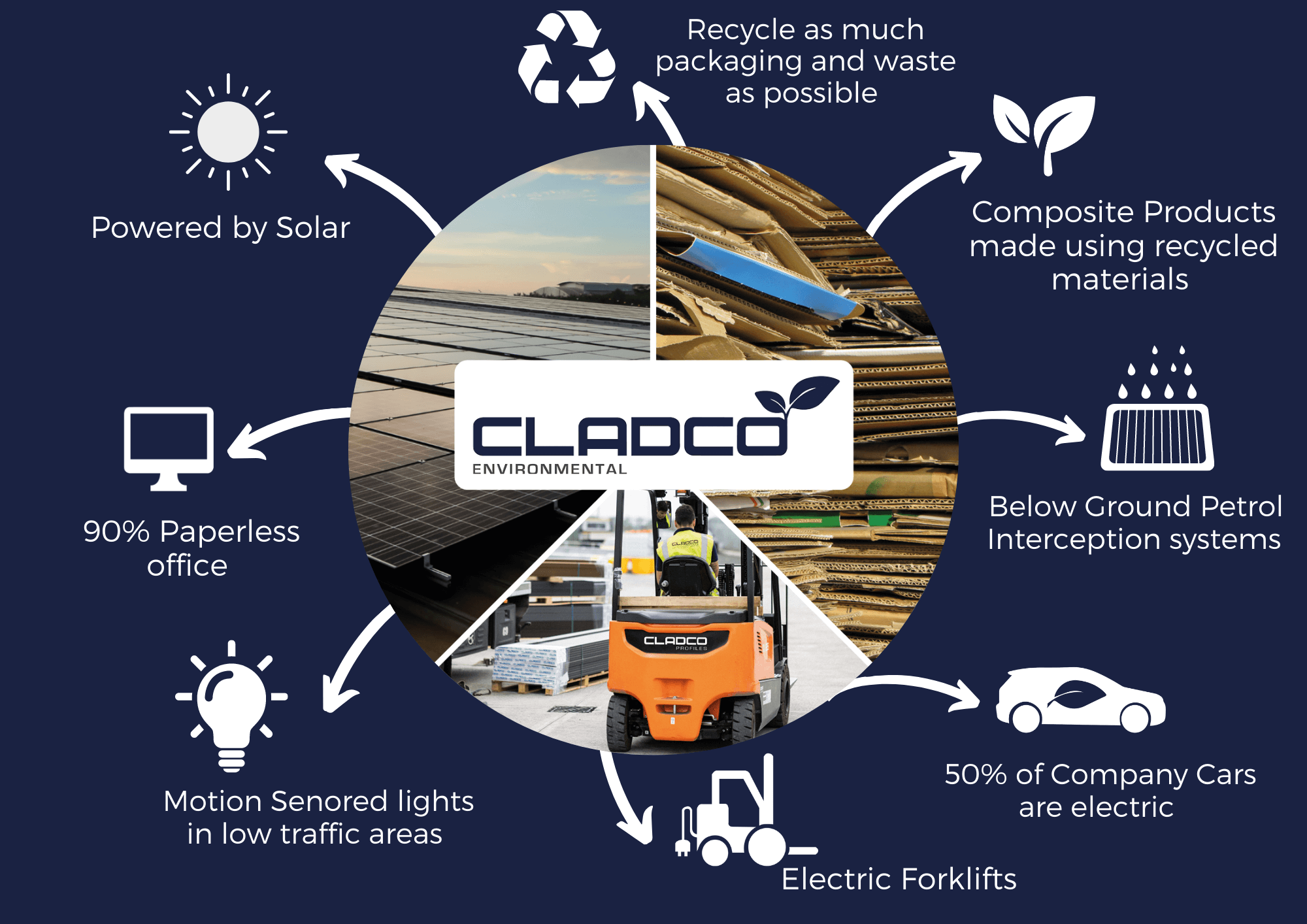

At Cladco Profiles, we are committed to promoting an ethical and environmentally responsible future. Not only do we integrate sustainability into our day-to-day operations, but we also continually review our processes to reduce our environmental impact.

As a business, we focus on three key areas to help minimise our carbon footprint and drive positive, lasting change:

Recyclable

Responsible

Renewable

Supporting well-managed forests and recycled sources with FSC® Certification.

The Forest Stewardship Council, also referred to as FSC®, is an internationally recognised, non-profit organisation dedicated to advocating responsible forestry practices.

The FSC® are involved in certifying forests around the world to ensure the very highest environmental and social standards are met. The FSC® has two components in their global forest certification system:

- Forest Management

- Chain of Custody

Although reforestation methods, such as hand-planting, are helpful in combating land degradation, it is vital to control production and ensure restrictions are in place. By using recycled hardwood fibres in our Signature and Pro-Range composite products, we are not contributing to deforestation and are preventing materials from going to waste.

Playing a critical role in addressing environmental concerns.

As an ISO 14001-accredited business, we adhere to the International Standard for Environmental Management, which ensures we continuously reduce our environmental impact. Through our commitment to high-quality, eco-friendly products, we strive for strategic business growth alongside environmental responsibility.

This accreditation highlights our focus on waste reduction and energy conservation, while guaranteeing regulatory compliance at Cladco Profiles. It reflects our dedication to ongoing environmental improvements and meeting all relevant regulations.

- Pollutant emissions

- Biodiversity loss

- Resource consumption

- Climate change

- Resource depletion

Recyclable

Our commitment to environmental well-being is ingrained in every part of our business, and we take daily steps to recycle materials wherever possible.

- Our range of 100% recycled plastic products, including decking boards, furniture, plus cladding and decking framework, can all be recycled at the end of their life.

- Our composite products, made from a mix of recycled hardwood fibres and recycled plastics, are responsibly sourced to reduce landfill waste.

- The hardwood fibres in our products come from recycled timber, helping to combat deforestation and protect forests and woodlands.

- Our steel coils, including inner tubes, are fully recyclable, as are our sample boxes and postage bags. Overall, 99% of all Cladco packaging is recyclable.

- All steel sheet offcuts are collected, weighed, and, where necessary, processed before being sent to recycling plants across Europe and worldwide.

RESPONSIBLE

Around 16.5 million tonnes of plastic enter our oceans each year, while an estimated 15 billion trees are lost to deforestation.

At Cladco, we’re determined to help change that by designing and supplying products that reduce environmental impact and plastic pollution.

- Our expanding range of composite decking, cladding and fencing is made from responsibly sourced recycled hardwood fibres and post-consumer plastics. These products help reduce landfill waste and support a more sustainable environment.

- Each year, Cladco Profiles prevents an average of around 6,240 tonnes of plastic from going to waste through composite product sales alone.

- Our 100% recycled plastic products, manufactured from post-consumer food packaging, drinks bottles and similar materials, offer a durable and sustainable alternative to traditional timber. By giving plastic waste a new life, these materials reduce landfill dependence, cut emissions from incineration, and provide customers with a long-lasting alternative to timber.

Renewable

As a responsible business, we're continually exploring new ways we can use renewable energy within our daily processes, which is a key step toward a more sustainable future.

- Solar panels have been installed at our headquarters in Okehampton, Devon, to power the machinery used to roll and press our steel roofing sheets.

- We also operate an in-house filtration system to deionise the water used for our forklifts, helping to prevent thousands of plastic bottles from entering landfill sites or the ocean.

- Since purchasing our first electric forklift back in 1982, we have continued to expand our fleet. Today, over 50% of our forklifts across all sites are electric, helping to reduce emissions and support our long-term sustainability targets.

Environmental Policy

It is the organisation’s objective to carry out all necessary activities, to protect the environment and to continually improve the Environmental Management System through the implementation of the following:

- Assess and regularly re-assess the environmental effects of the organisation’s activities.

- Training of employees in environmental issues.

- Minimise material & energy wastage.

- Minimise the production of waste.

- Minimise the risk from operations and activities undertaken by the organisation.

- Promote the use of recyclable and renewable materials.

- Prevent pollution in all its forms.

- Control noise emissions from operations.

Top management demonstrates commitment with respect to the Environmental Management System by:

- Ensuring that the Environmental Management System achieves its intended outcomes.

- Directing and supporting persons to contribute to the effectiveness of the Environmental Management System.

- Promoting continual improvement.

- Supporting other relevant management roles to demonstrate their leadership as it applies to their areas of responsibility.

- Ensuring that the resources needed for the Environmental Management System are available.

- Taking accountability for the effectiveness of the Environmental Management System.

- Ensuring that the Environmental Policy and Environmental Objectives are established and are compatible with the strategic direction and the context of the Organisation.

- Ensuring the integration of the Environmental Management System requirements into the Organisation’s business processes.

- Communicating the importance of effective environmental management and of conforming to the Environmental Management System requirements.

Cladco Profiles is proud to save an average of

520 MILLION PLASTIC BOTTLES

from polluting our oceans per year. This equates to

6240 TONNES OF PLASTIC

Composite Products

All of our composite products - including decking, cladding and fencing - are made from recycled hardwood fibres and recycled plastics, combined with bonding agents, colour tints and additives to create durable, low-maintenance materials.

In 2023, our composite products were re-certified as FSC® (100% recycled), reinforcing their sustainable credentials and further reducing environmental impact.

Discover more about our FSC® certification and explore practical ways to recycle composite decking in our informative environmental articles.

Recycled Plastic Products

We have a wide range of recycled plastic products here at Cladco, providing our customers with sustainable and eco-friendly alternatives to timber and composite materials.

From durable outdoor furniture to cladding battens, decking boards, or frame joists and posts, our recycled plastic products are manufactured from 100% recycled plastic, offering a long-lasting and low-maintenance solution for modern projects.

Find Out More

Discover some of our Blogs you may find helpful, including our journey to obtaining ISO accreditations and how your garden can impact climate change.