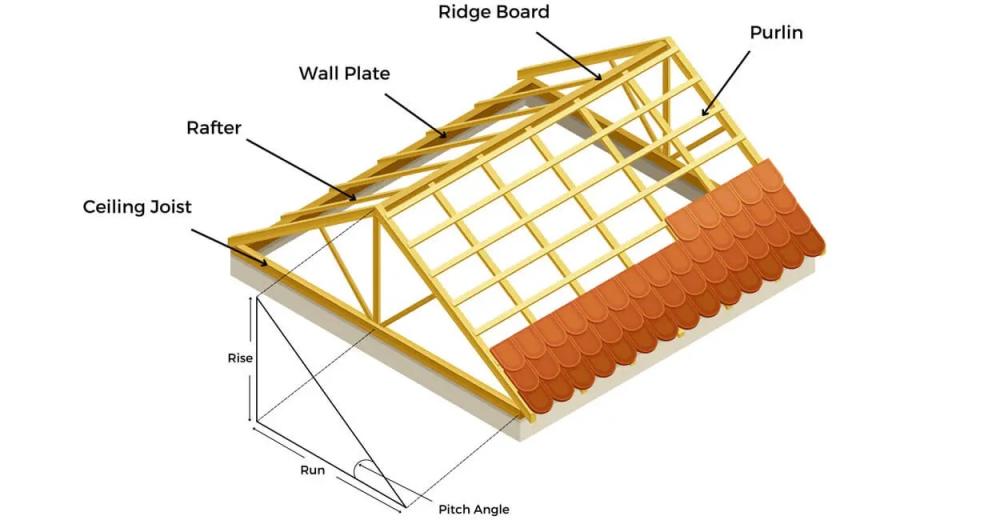

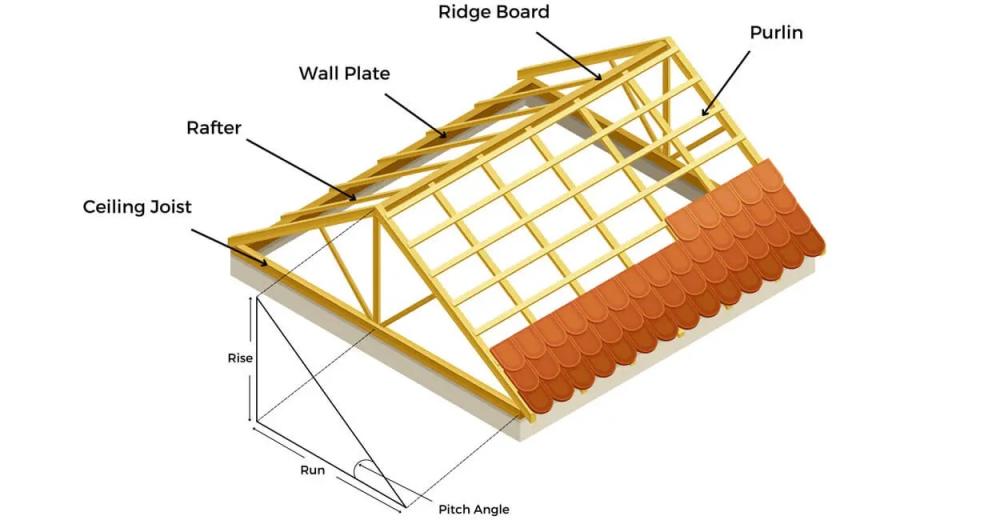

A pitched roof is a roof that has been installed with a slope. The slope of a roof can vary in angle, running from the apex of a building (from its ridge board) down to the base of the roof (to its eaves).

Rising from the horizontal span, the angle determines the steepness, which is calculated in a couple of ways and represented as either a ratio or a degree. For all roofs, measuring this is a necessity, as it informs your choice of roofing, the length of rafters and how your materials are measured and cut.

Unlike a flat roof, or one with a shallow pitch, a pitched roof will improve water run-off into gutters and reduce the build-up of debris, making sure your roof lasts a lot longer with much less need for ongoing maintenance.

Types of pitched roofs

Single pitched roofs

A single-sided roof, also known as a mono-pitch roof, has just one slope rather than two adjoining sides. Common examples include lean-to extensions, single-slope shed roofs, and garage roofs. Unlike traditional pitched roofs, there is no ridge board at the apex.

Due to only one side of the roof requiring construction, a single-pitch roof structure provides a faster installation process. The increased vertical rise of a roof area will increase the materials required and make installation more difficult than lower pitched roofs.

Dual pitched roofs

Dual-pitched roofs have two sides sloping down from either side of the apex (the topmost section of the roof truss or ridge board) towards the bottom corner, or eaves, of the roof.

Thanks to this type of roof's design, benefits can include having more loft space that increases further with the size of the roof and a greater pitch angle. Additionally, these types of roofs are more structurally sound due to the fixed triangular design of the roof covering and timber truss supports.

Pitched roofs are commonly installed using a system of rafters, purlins and trusses constructed out of timber. The latter will be preferred for larger building types, providing improved structural support across the span of the roof and for a gable roof end.

How is roof pitch calculated

To calculate the roof pitch, you will need good access to your roofing structure to take the measurements of the horizontal span, or run, from the lowest corner of the roof to the central point directly under the apex (ridge board).

Next, take the vertical height, or rise, from the central point under the apex to the roof's ridge board. The vertical rise divided by the run will give you the tangent. We recommend using the online roofing pitch calculator at Calculators.io to work this out quickly for you.

The roof pitch is displayed either as a degree or a ratio, for example, 14°, or the equivalent ratio of 3:12. The latter calculation shows for every 12 inches along the horizontal span, or run, the roof rises by 3 inches vertically.

What is the minimum angle for a pitched roof?

The minimum angle for a roof is generally considered as 4°, or just under 1/12. Only certain materials will be able to install down to this due to reduced water run-off efficiency and stability, so it's important this angle is calculated before buying any materials.

Box profile roofing sheets can be installed down to a minimum 4° pitch, which makes them ideal for a lean-to roof, single-sided garage roofs, or sheds with a nearly flat roof. Other options include standing seam roof sheets, which can be installed as low as 6°, corrugated roofing sheets which can be installed down to 10° and tile effect roof sheeting which can be installed down to 12°.

Ready to choose the right roofing sheet for your project? Explore our full range online to compare profiles and finishes, order a sample to check the quality before you buy, or speak directly to our friendly sales team on 01837 659901 for expert advice and guidance.

Step by step guide - Constructing a pitched roof

How to build a pitched roof for a shed

Single pitch

Step 1 - Check planning permission

For any new building project, start by checking whether or not you require planning permission for your shed. We discuss this in our planning permission article.

Step 2 - Measure the roof

Measure the length and width of your shed roof to determine the number of materials that will be needed and the overall shape. Take into account the overlap of roof sheets, and check the manufacturer's recommendations to determine the quantities you will require.

Step 3 - Buy your materials

The angle or pitch of your roof will determine which materials are best suited. Some roof coverings, such as corrugated roofing sheets, will require a minimum pitch of 10° (just over 2/12).

Our handy roofing calculator makes it easy to estimate the sheets, fixings, and flashings required for a single-sided roof.

We also recommend you check that you have the required PPE, such as safety gloves, as well as either mastic lapping tape for box profile and corrugated roofing sheets, or silicone sealant for tile form roofing.

Step 4 - Install rafters and purlins

Secure your timber rafters from the barge board to the ridge board, at distances of 300mm-600mm apart. Allow for enough overhang at the eaves (the lowest end) to allow for effective water run-off.

When using steel roofing sheets, purlins will need to be installed across the width of the roof, crossing and securing onto the rafters to prevent the sheets from flexing in the wind. Purlins need to be installed at a maximum of 1.2 metres apart for 0.7mm thick sheeting, and up to 1 metre for 0.5mm thick sheeting.

Step 5 - Install roof materials

Install the roofing sheets onto the purlins using the recommended fixings, whether you are installing onto steel or timber purlins.

Foam fillers are recommended for metal roofing sheets to go underneath the eaves to add a layer of protection from insects, pests and the weather.

Step 6 - Finishing touches

Install corner barge flashings along the side edges of the roof for added aesthetics and protection. Custom fascia trim flashings are also a great addition to complete the look.

Dual pitch

Step 1 - Measure

Start by working out the square meterage of your roof by multiplying the horizontal length with the length of your rafters. For dual sided roofs, this figure will be doubled. Alternatively, use our roofing calculator to work this all out for you.

Step 2 - Buy materials

Create your shopping list, making sure to include fixings, purlins, rafters and PPE. Read our article on shed roofing options for more details.

Depending on the size of your shed, this will determine how many roof trusses or rafters you will need to be able to support your roof.

For most standard sized garden sheds (e.g. 8x6 feet), rafters can be installed from the base of your roof to the apex ridge board, instead of using trusses. Common rafters use timber 2" x 4" sized boards.

Step 3 - Install braces

For small shed roof builds, permanent bracing will likely not be required as the gable ends will be built as part of the wall.

Step 4 - Include purlins

If you plan on installing roofing sheets, include horizontal timber or steel Z purlins to prevent the steel sheets from flexing. Purlins will need to be fixed to the rafters at a maximum of 1.2m apart (0.7mm thick sheets), or 1m apart (0.5mm thick sheets).

Step 5 - Install roofing materials

Install roofing materials once your rafter and purlins are in place. Lap metal profiled sheets by one profile (when choosing box profile or tile form) and one and a half profiles for corrugated sheeting. Secure sheets using appropriate fixings and remember to allow for overhang at the eaves.

For full details on installing steel sheet roofing material, visit our Roofing Help & Advice section.

How to build a pitched roof for a garage

Single pitch

Step 1 - Order materials

You will want to consider the design of your garage roof compared to the surrounding areas to help it blend in or contrast the local area. Whether you are installing an enclosed garage or an open-sided carport, the first step is measuring the width and depth of the roof.

Step 2 - Build ceiling joists and rafters

Construct the initial line of rafters according to the angle of the roof and cut joists accordingly. Secure the ends of the rafters to the wall plates at the eaves and to the ridge board.

Step 3 - Include purlins

Much like a shed roof, if you plan on installing roofing sheets, include horizontal timber or steel Z purlins to prevent the steel sheets from flexing.

Step 4 - Install roofing

Starting from one corner, work your way across the roof, overlapping steel sheeting by one profile for box profile or tile form, and 1.5 profiles for corrugated, and securing with stitcher screws and fixings, as well as silicone sealant for tile form sheeting or mastic lapping tape for box profile or corrugated.

Dual pitch

Step 1 - Measure and buy materials

Similar to above, the shape of the roof is measured in the same way, accounting for both sides of the building with identical dimensions.

Step 2 - Build roof trusses

For a larger building, trusses will need cross beams (ceiling joists) fixed to create a stable construction for the roof.

Ideally, each truss should be 600mm (24 inches) apart at most. This can be as low as 300mm (12 inches) or 400mm (16 inches), where required, to provide adequate support for the purlins.

Collar ties can be installed across the span of the apex section of the truss construction, fixed from rafter to rafter from the ridge board.

Step 3 - Install braces

For larger buildings, trusses will need to be braced to provide temporary support to then install the trusses. Nail a 2" by 6" timber support beam to the centre of the end truss down to the ground for a central brace.

Step 4 - Include purlins

The steps involved in installing a garage roof with a dual pitch are similar to a single, with the opposite side being a mirror image. Be sure that the first and second row of purlins will align with the first and second row on both sides with matching dimensions.

Step 5 - Install roofing materials

For roofing tiles, be sure to follow the product guidelines for adequate overlap. It is worth obtaining a few quotes from local contractors before proceeding.

How to build a pitched roof for an extension

Single pitch OR lean-to roofs

Step 1 - Check for planning permission

Extensions may require planning permission from your local planning authority. We talk in-depth about planning permission for your roof extensions in our blog, which you can read here. Lean-to roofs are installed against the back wall of a house and can span the length of the entire wall.

Step 2 - Secure your ledger

A ledger board will enable your single-sided roof to connect to your existing structure on the external wall. Be sure to account for your 'height above plate', which includes the height of the rafters once installed plus the height of the rise.

Step 3 - Wall plates

Fix a timber wall plate onto the top of your external walls to allow the rafters to be installed. Wall plates will give a brick wall, for example, a suitable wall plate covering that can be screwed into.

Step 4 - Install rafters

Measure each rafter to include an overhang. Rafters should be placed 24 inches (2 feet) apart at regular intervals to allow intermediate support. Cut your notched bird's mouth to sit onto the wall plate.

Install joist hangers along the ledger to secure your rafters in place.

Step 5 - Roofing materials

For a low-pitch roof, steel box profile roofing sheets can be installed from a minimum of 4° from the corner upwards across the building structure.

Step 6 - fascia boards

A custom steel fascia trim can be installed to cover a small gap by the roofing with an edging piece. This can help to hide the wall plate onto which the rafters are secured to.

Last Updated: November 27, 2025

Please note all information is correct at the time of writing. However, we encourage you to do your own research to ensure it remains accurate and relevant to your needs.