Cutting Sheets On-Site

Cladco Profiles will deliver your roofing sheets to you at the exact size you need them, so providing you send over the correct measurements, you shouldn’t need to cut them yourself. We do understand, however, that sometimes this cannot be avoided, and you may need to further trim your cladding. In this instance, we have some recommendations which should aid you in cutting your sheets effectively in the shortest amount of time possible, with no mistakes.

If necessary, we recommend seeking advice from a professional prior to cutting sheets.

Firstly, you’ll need to ensure you take measurements of the roof, so you know exactly how much you need to cut. Never guess this step, it could end up being a costly mistake. Mark the cut-lines with a felt-tip pen or a Sharpie: a pencil won’t do this time.

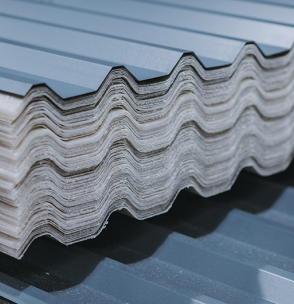

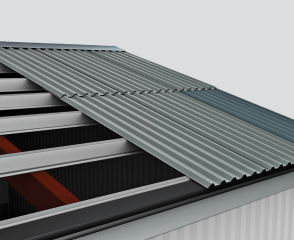

If you need to cut your roof, we always recommend doing so on the ground. Cutting metal while on a roof is dangerous and could result in serious injury. Lay your profile sheets face down across padded supports. Doing this will stop scratching and will make the process much easier.

When choosing your tools, If necessary, we recommend seeking advice from a professional. You may wish to use a tool that will produce as little heat as possible. Heat can damage the coating on the sheet and thus cause discolouration, scratching and in some respects could ruin your anti-condensation felt attachment. For longer, straight cuts using a circular saw with a fine-tooth metal cutting blade that produces a cold cut is often advised. If you only need to make smaller cut-outs and openings, or for cuts that are not straight, a jigsaw or reciprocating saw may be recommended by a professional.

In some instances, you may be recommended to use an angle grinder with a small tooth blade or disc when cutting metal classing. Reciprocating nibblers are widely used in the roofing trade, and these produce an excellent, clean cut.

As you can see, there are a wide variety of tools you may wish to use when cutting sheets, however you must always seek advice before cutting from a qualified professional. Cladco accept no responsibility for any injury or accident that may have occurred by using the above tools. We do not recommend any specific tools but recommend the advice from a qualified professional.

Remember to remove any swarf with a brush to prevent damage to the sheet.