Whether you're looking for a new roof for your shed, agricultural barn or commercial building, you've probably already discovered there are plenty of materials to choose from. Two of the most popular roof coverings are plastic and metal options, which have a variety of benefits.

In this article, we'll take a look at how they compare in terms of cost, maintenance, appearance, and overall lifespan for both plastic and metal roof options.

Plastic roofing materials

Polycarbonate roofing sheets

Polycarbonate roof sheets are a lightweight, durable roofing material often used on greenhouses and conservatories as a roofing product.

The transparency of the material allows natural light to flood the space, brightening interiors and creating a more comfortable environment. This keeps the building warm when the sun is shining, whilst trapping high temperatures and saving on heating costs. Built-in UV protection means you can enjoy the benefits of sunlight without the risk of harmful rays.

Also used for domestic skylights, polycarbonate is a cheaper alternative to glass that is lightweight, easier to install and less fragile. Polycarbonate sheets are also manufactured in a variety of profiles, with corrugated plastic, twinwall and flat sheets being among the most commonly used.

Cost: Polycarbonate sheets are a cheaper alternative to glass, whilst being easier to install and more durable.

Ease of Installation: Due to their lightweight structure, polycarbonate roofing sheets are easy to handle and install. Unlike glass, they will not smash if dropped or mishandled at height and are virtually unbreakable due to their modular structure.

Maintenance: These plastic sheets have a tendency to attract moss and algae, especially over the winter months. This means they will need regular cleaning for optimum light transmission as the seasons change.

Durability: Polycarbonate sheets are exceptionally strong and durable thanks to their bonded chemical structure and high volume of bonds.

Aesthetics: A downside to polycarbonate roofing sheets is that they are not as aesthetically appealing as real glass sheets. Whilst they suit buildings like greenhouses, they do not work so well on household roofs due to staining and potential algae build-up.

GRP (Glass Reinforced Plastic) roof sheets

GRP roof sheets, also known as roof lights, are manufactured from high-grade glass-reinforced plastic, with Cladco GRP roof lights being 1.5mm thick for added strength and longevity. They have a resin-enriched gel coating which protects the roof lights from harmful UV rays whilst permitting an 80% light transmission rate. The gel also prevents moss and discolouration from occurring over time.

They are often installed on animal barns, cattle sheds, and other buildings that require natural daylight to create a more comfortable living environment.

Cost: GRP roof panels are a more expensive option compared to polycarbonate sheets, starting at roughly £44 per 2.5m. The higher cost is offset by their longevity and reduced maintenance compared to plastic roofing sheets.

Ease of installation: Cladco GRP roof lights are a versatile option and can be installed at a minimum pitch of 10°, alongside a variety of other metal roof sheets. These include corrugated and box profiles, and together create a seamless, metal roof.

Maintenance: Cladco glass-reinforced plastic roofing panels feature an antifungal gel layer, reducing maintenance needs for years to come.

Durability: Cladco GRP roof lights provide protection from high winds, heavy rainfall and harsh weather conditions. This keeps the building and its contents safe thanks to GRP's strong reinforced materials.

Aesthetics: GRP sheets are well-suited to commercial and agricultural-style projects. They would not necessarily suit the aesthetics of a home or garden shed roof due to their heavy structure and industrial appearance.

Bitumen roof sheets

Bitumen is a widely used material in various roofing projects, particularly for garage roofs, garden sheds, and small garden rooms. It is made from asphalt and blended with polymerised plastic or occasionally rubber. This mixture is then reinforced with fibreglass to create a flexible, waterproof membrane that can be either nailed down or adhered to flat or low-pitched roofs. Bitumen is available in rolls that can be rolled out across the roof space or as individually cut shingles.

Cost: Bitumen is one of the most cost-effective choices for roofing materials, whether plastic or metal, with prices starting as low as £5 per square metre. Additionally, it can be easily installed by someone without professional experience, which helps save on potential labour costs.

Cost: Bitumen is one of the most cost-effective choices for roofing materials, whether plastic or metal, with prices starting as low as £5 per square metre. Additionally, it can be easily installed by someone without professional experience, which helps save on potential labour costs.

Ease of installation: Most bitumen roofing sheets require very few tools to fit, and many options come with a self-adhesive layer on the underside of the sheet, helping to ensure a quick, hassle-free installation. The shingle version, whilst still being easy to fit, requires a little more time and patience due to the individual tile-like elements. They need to be fitted one at a time in an overlapping method.

*Please note: some bitumen sheets will need professional tools to install, such as a high heat source like a roofing torch.

Maintenance: As bitumen roofing is generally fitted on flat or low-sloping roofs, you will need to keep them well maintained. Regularly removing and brushing away leaves and debris, especially in the autumn months, is a must. If not, this can lead to a build-up of unnecessary weight on the structure of the building and cause potential damage from water pooling.

Durability: Bitumen roofing options do not last as long as some of their plastic roofing counterparts, such as polycarbonate sheets. They last on average 15-20 years in normal environments. Over time, thinner sheets are susceptible to tearing and lifting at the edges, meaning damaged sheets will need replacing.

Aesthetics: Often associated with garden sheds, the attractiveness of bitumen sheets is considered quite low. Ideal for use on low or flat roofs in gardens, they would generally not be considered a stylish option for domestic roofing projects.

Metal roofing materials

premium materials for all our profiles, including 32/1000 and 34/1000 box profile, 13/3 corrugated, 30/500 standing seam and 41/1000 tile form sheets. Cladco metal roofing sheets are available in a range of coatings and colours to suit the style of any design.

Metal roofing sheets are a great option for agricultural, commercial, and industrial applications due to their strength and durability. More recently they have seen a rise in popularity on domestic builds when used as both a roofing and wall cladding material.

Box Profile roof sheets

32/1000 and 34/1000

Box profile roof sheets by Cladco are available in either 32/1000 or 34/1000, with both manufactured from premium galvanised steel.

Cladco 32/1000 sheets feature 6 x 32mm high profiles across the entire sheet, which sits at a lower height than the 34/1000 profile, which features 7 x 34mm high profiles.

Cost: Sheets start at £9.36 per sheet (0.5mm thick plain galvanised) and can range in price according to the thickness and any coating that might be applied.

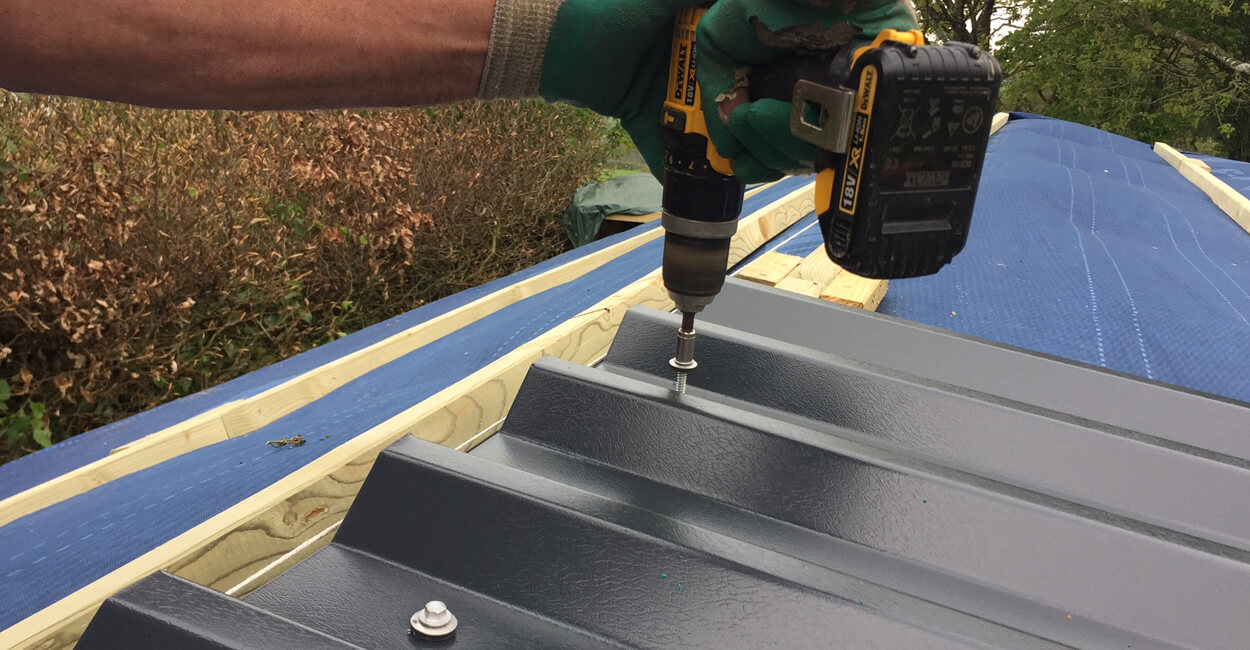

Ease of Installation: Box profile metal roofing sheets can be installed to a pitch of at least 4°, providing a 1m coverage when lapped. Care must be taken when installing steel roof sheets due to their sharp edges and weight. It is recommended that at least two people are on hand to manoeuvre and carry any metal roofing material.

For more information on installing Cladco box profile sheets, take a look at our helpful installation guides for 32/1000 and 34/1000.

Maintenance: Cladco box profile roof sheets are low-maintenance, with their ribbed profile encouraging rainwater and debris run-off, whilst improving impact resistance. If paired with a PVC plastisol coating, the metal sheets can be expected to last up to 40 years in the correct conditions.

Durability: Box profile sheets are available in either 0.7mm or 0.5mm thicknesses. 0.7mm provides higher tensile strength, and 0.5mm thickness is ideal for siding or smaller projects. Both thicknesses are tested to current CE EN 14782 standards. The scratch-resistance of each sheet can be improved with the addition of protective coatings.

Aesthetics: Traditionally associated with an industrial or agricultural appearance, box profile roofing has become an increasingly versatile roofing solution thanks to its modern colour and coating options. Our PVC plastisol sheets feature an authentic leather-grain texture and are offered in a wide palette, including black, anthracite, juniper green and slate blue. For a sleeker look, polyester-painted sheets provide a glossier finish, although in a more limited colour range.

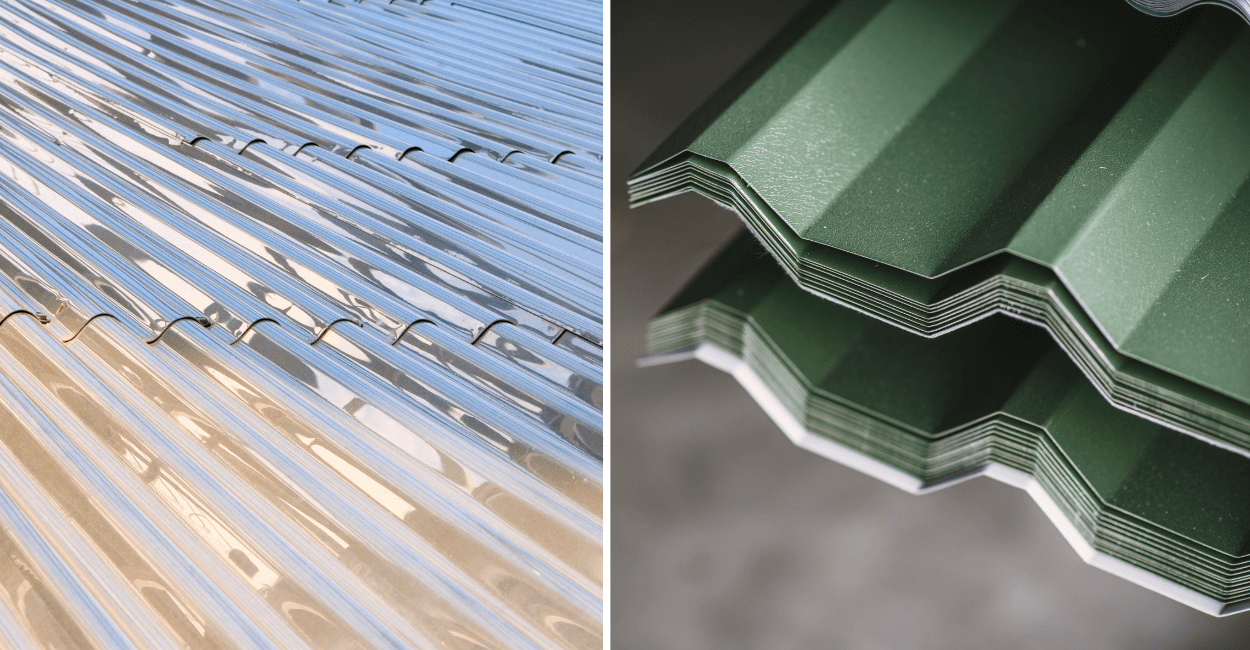

Corrugated steel roofing sheets

Corrugated roof sheets are a favoured roofing profile in both metal and other materials. Cladco 13/3 corrugated sheets are a popular metal roofing choice suitable for agricultural, industrial, and now more than ever, domestic applications.

Their waved profile improves structural strength whilst enabling efficient rainwater runoff. They have recently seen a surge in popularity as a cladding material on contemporary home designs, too, especially black-coloured cladding.

Cost: Corrugated roofing sheets start at £9.36 per sheet (0.5mm plain galvanised) and can range in price according to the thickness and any coating used. For example, 0.7mm corrugated roofing sheets with a PVC plastisol coating start at £16.36 in comparison.

Ease of installation: 13/3 corrugated roof sheets by Cladco can be fitted to a minimum pitch of 10° and provide a 1 metre coverage when lapped. Care must be taken when installing metal sheets due to their sharp edges and weight. It is recommended that at least two people are available to handle any roofing panels. For more information and further guidance, take a look at our guide.

Maintenance: Cladco corrugated roof sheets require minimal upkeep, with their curved profile helping rainwater and debris to run off easily while also enhancing impact resistance. When finished with a durable PVC plastisol coating, the sheets can achieve a lifespan of up to 40 years under suitable conditions.

Durability: Our 13/3 corrugated sheets come in two thickness options: 0.7mm and 0.5mm. The 0.7mm thickness offers greater tensile strength, while the 0.5mm thickness is ideal for siding applications. Both thicknesses meet the current CE EN 14782 standards. To enhance durability further, protective coatings can be added.

Aesthetics: Corrugated roofing options have always had an association with agricultural buildings. Now, however, roof styles are easy to update thanks to a selection of coatings and colours to suit. PVC plastisol is available in a range of colours and provides an authentic leather-grain finish to the texture of the sheet. Polyester paint is available in a smaller selection of colours and provides a glossier finish to the sheets.

Tile Form sheets

Cladco tile form roof sheets are designed to replicate the look of traditional roof tiles. Applied in large panels, they are a great way to achieve a traditional look to the design of your building and are developed to last.

Cost: Tile effect metal roofing sheets are a more expensive option in the grand scheme of metal roofing options. Prices start at around £22.50 for a 0.7 sheet. This is because their unique profile requires extra attention during the manufacturing process. The GreenCoat® Pural BT coating is also a premium option which extends the quality of the roof, and the cost.

Ease of installation: When compared with the other roof options, tile form sheets require extra care during installation. You may need a professional to fit it if you are uncertain or inexperienced. For some additional advice, take a look at our installation guide here.

Maintenance: Thanks to their single-sheet design, tile effect roofing avoids the common problems seen with traditional tiled roofs, such as cracked or dislodged tiles. Maintenance is minimal, usually limited to brushing away leaves or debris that may collect on the waved profile.

Durability: Tile effect metal roofing sheets are manufactured with a GreenCoat® Pural BT coating. This improves the structure of the sheet, making them more durable and improving wear and weather resistance.

Aesthetics: Tile effect sheets are an appealing option for those needing a new roof for their domestic project. This is because of their similarities to clay shingles and tiles. Available in Nordic night black, silver fir green, slate grey and tile red, there is a suitable colour for homes, garden rooms and summerhouses alike.

Standing Seam sheets

Cladco standing seam roof sheets, manufactured from SSAB Swedish steel with GreenCoat® Pural BT coating, offers a sleek concealed-fix design, long-lasting durability, and A1 fire rating. Ideal for roofing or cladding, with ribbed or unribbed options available.

Cost: Sheets are available in both ribbed and unribbed designs, each priced at £20.70 per sheet. Ribbed sheets feature fine reinforcing ridges that help to reduce drumming and oil canning in high winds, while unribbed sheets offer a completely smooth, modern finish often chosen for aesthetics.

Ease of installation: While standing seam sheets may be a little tricky for those with no roofing experience, competent roofers should find these sheets straightforward to fit. With a wide choice of flashings and accessories available, achieving a professional, secure finish is made much easier.

Maintenance: Standing seam roofing requires very little upkeep, though regular checks for debris, sealant condition, or signs of corrosion are recommended. Keeping the roof clear of leaves and twigs will help preserve both appearance and performance. The GreenCoat® Pural BT coating provides an additional durable protection, and any scratches can be treated with colour-matched metallic touch-up paint to guard against rust.

Durability: Manufactured from high-quality SSAB Swedish steel and coated with GreenCoat® Pural BT, standing seam sheets are designed to withstand even the harshest weather conditions, UV exposure, and general wear. With correct installation and maintenance, they can provide reliable performance and a lifespan of up to 40 years.

Aesthetics: With their concealed fixings and sleek, modern profile, standing seam sheets offer a clean architectural look suited to both contemporary homes and commercial buildings. Available in ribbed or unribbed styles, they deliver either a subtly reinforced design or a smooth, minimalist finish.

As you can see, when it comes to plastic vs metal roof sheets, there are benefits on both sides, with the final decision depending on which factors you prioritise, whether the overall price, aesthetics, ease of installation, or the level of maintenance required.

Plastic sheets are lightweight, affordable and simple to fit, making them ideal for smaller or temporary projects. Metal roofing, by contrast, delivers superior strength, durability and long-term value, with modern colour and profile options making it a versatile choice for domestic, agricultural, industrial and commercial applications.

Last Updated: September 19, 2025

Please note all information is correct at the time of writing. However, we encourage you to do your own research to ensure it remains accurate and relevant to your needs.