Side & End Laps

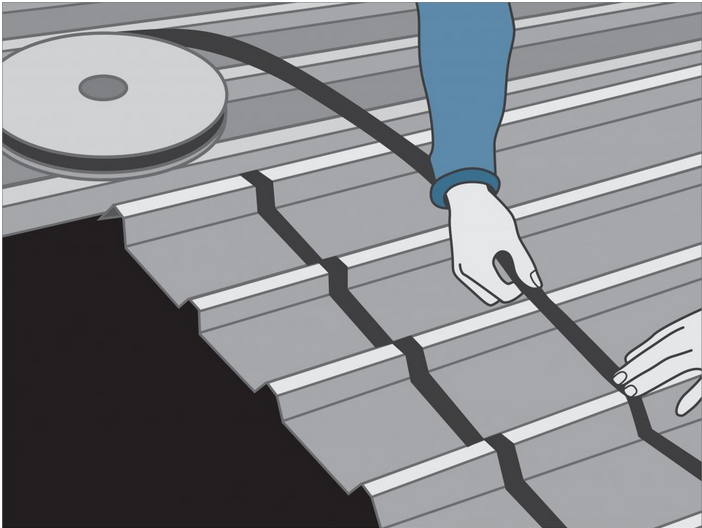

Side end laps benefit from mastic lapping tape and stitcher screws, these materials provide a weather proof joint on side laps helping to protect the interior from the elements. Cladco Mastic Tape should be installed along the crest of the sheeting. Mastic lapping tape can often be considered more effective than silicone sealants.

Cladco Stitcher Screws can be used at 600mm spacings down the sheet which will then consolidate the join between sheets with lapping tape between. This is the most effective way to seal end joints.

Roofing Sides & Lap Joints

When overlapping you should ensure a minimum overlap of 250mm, this will ensure enough of the steel sheeting is covered. The overlap section should be supported by a purlin below.

Side lap roofing should use mastic lapping tape across the width of the sheet to create a rain and weather resistant seal. Its advisable to leave a 25mm gap at the ends of the top and bottom.

Ensure you are happy with the placement of sheets before applying the mastic lapping tape as its very difficult to remove the sheets, ensure the sheet is positioned perfectly before securing.

Roofing Side Laps & Further information at Cladco

Roofing projects can be difficult and it’s never easy trying to complete a project by yourself, that’s why here at Cladco profiles we have a team of experts on hand to assist you with every step of the way, simply call us on 01837 659901 or contact us here.

The help & advice section will help you with questions and queries and even maintenance for your steel sheeting.

The FAQs section of our website can help you with queries and questions you may have surrounding how to install or look after your steel roofing sheets.