Recycled Plastic Decking Installation Guide

Installation Guide, Aftercare, and FAQs

Before You Begin

DISCLAIMER

This information is provided as general guidance only. It does not replace a site-specific risk assessment or SSOW. Always follow current health & safety standards, regulations, and the manufacturer’s instructions for tools and equipment.

Storage, Colour and Warranty

STORAGE AND HANDLING

Cladco recycled plastic decking boards should be stored on flat, level surfaces and not left for prolonged periods in direct sunlight, as this can cause warping. Where possible, keep boards undercover to protect them from UV exposure.

Installation guidance is based on an ambient temperature of 20°C. Variations in temperature will affect the amount of expansion and flex in the boards.

Because the boards are made from 100% recycled plastic, dimensions may vary by up to ±3%. These tolerances are normal and not grounds for complaint.

Handle boards in accordance with your manual handling risk assessment and SSOW. Boards are heavy, so a two-person lift may be required.

COLOUR

The colour and surface texture of the boards will not be absolutely uniform due to the recycled nature of the material. Minor differences are inherent and should be anticipated as part of the character of the decking.

If boards have subtle variations in colour, these should naturally moderate over time. Exposure to sunlight and weather creates a gentle ‘settling’ effect over the first few months outdoors.

20 YEAR WARRANTY

The 20-year manufacturer’s warranty applies only if all installation and handling rules are followed as set out in the guide. Ignoring key steps (e.g. improper base, insufficient expansion gaps, wrong fasteners) can invalidate the warranty.

Tools and Equipment

PROTECTIVE EQUIPMENT

Wear the PPE specified in your risk assessment. This may include:

- Eye protection

- Respiratory protective equipment (RPE) where required

- Hearing protection when using power tools

TOOL SET

A standard toolkit with measuring tape, screwdriver, hammer, and cutting tools will cover most installation requirements.

POWER DRILL OR DRIVER

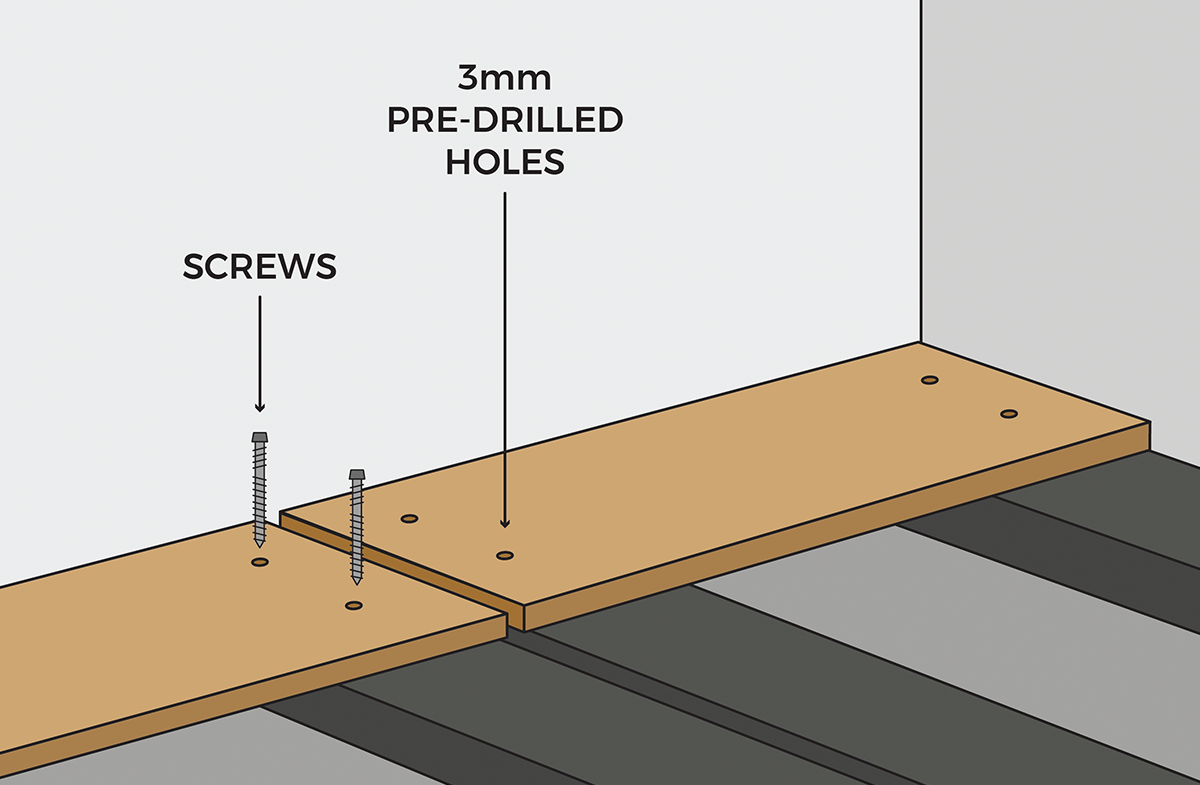

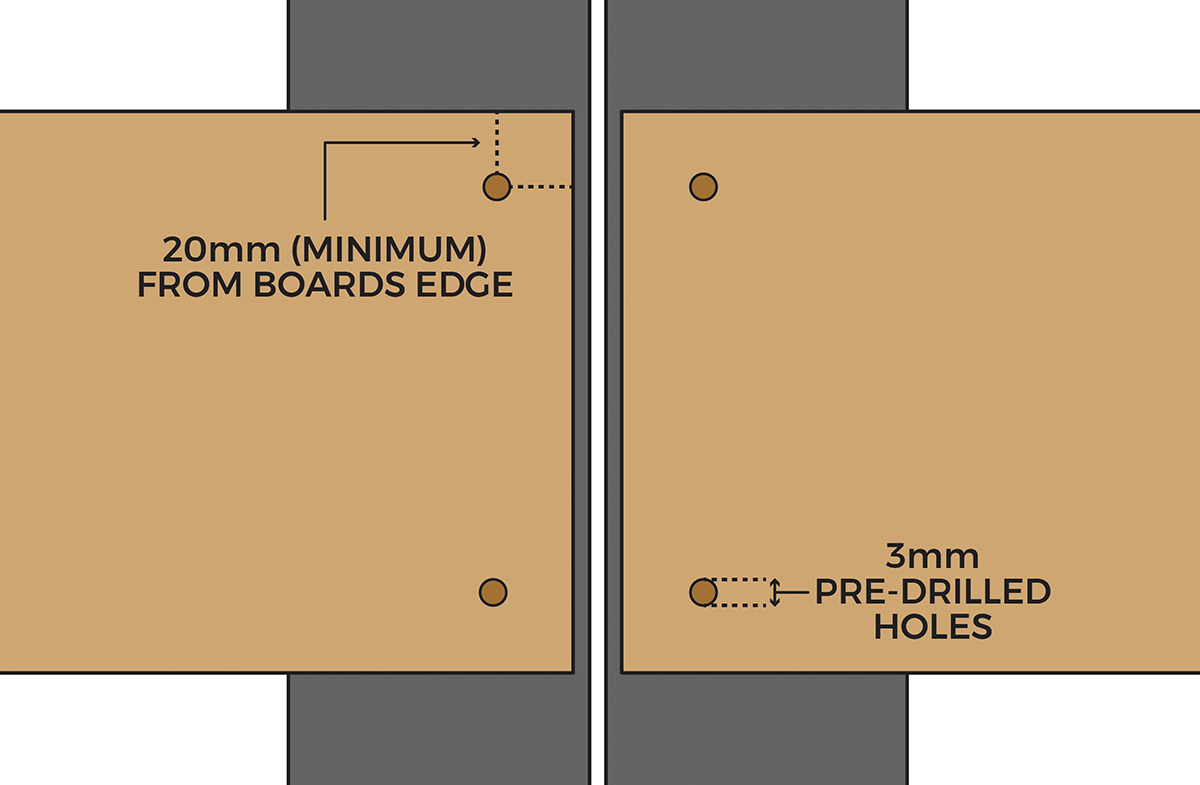

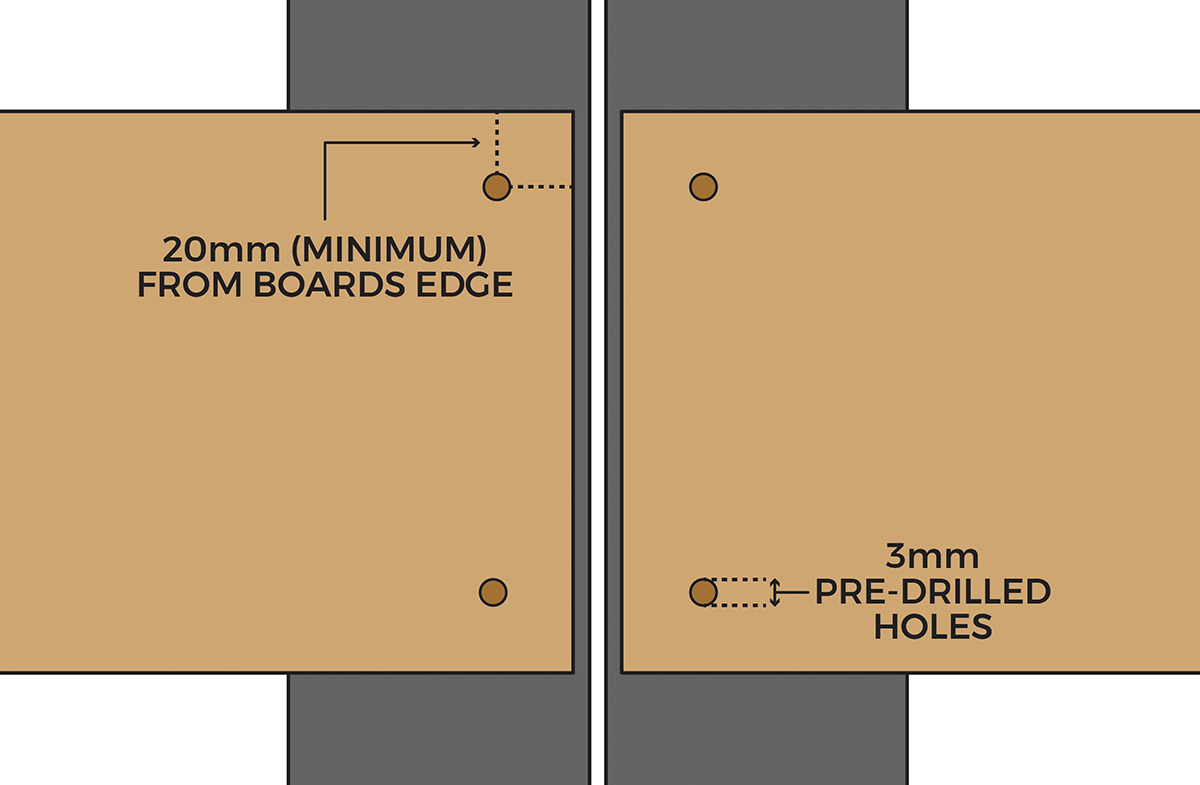

Use stainless steel chipboard screws with countersunk heads (V2A), 4.5mm × 60mm for fixing to the substructure. Our Cladco SPEEDDEKZ stainless screws or Nordeck screws with colour caps are also suitable. Boards can be pre-drilled and screwed in the same way as timber decking.

ELECTRIC SAW

Recycled plastic decking can be cross-cut using a suitable saw (e.g. circular saw or jigsaw) fitted with an appropriate blade or disc - check with the supplier or manufacturer of the blade/disc for suitability. Boards must not be cut lengthways (rip-cut). All cutting should be carried out by a competent person in line with the installer’s risk assessment and Safe System of Work (SSOW).

SPIRIT LEVEL OR STRING

A spirit level and string line will help maintain a consistent slope and straight alignment across your decking area.

Choose from two bases

CONCRETE BASE

If you have an existing stable concrete slab or terrace, it can serve as the base for your recycled plastic decking, avoiding the need for full subsoil excavation.

The surface must be load-bearing and frost-proof, with drainage maintained. A gentle slope of around 2% (approximately 2cm per metre) away from the property will allow rainwater to run off effectively and prevent pooling.

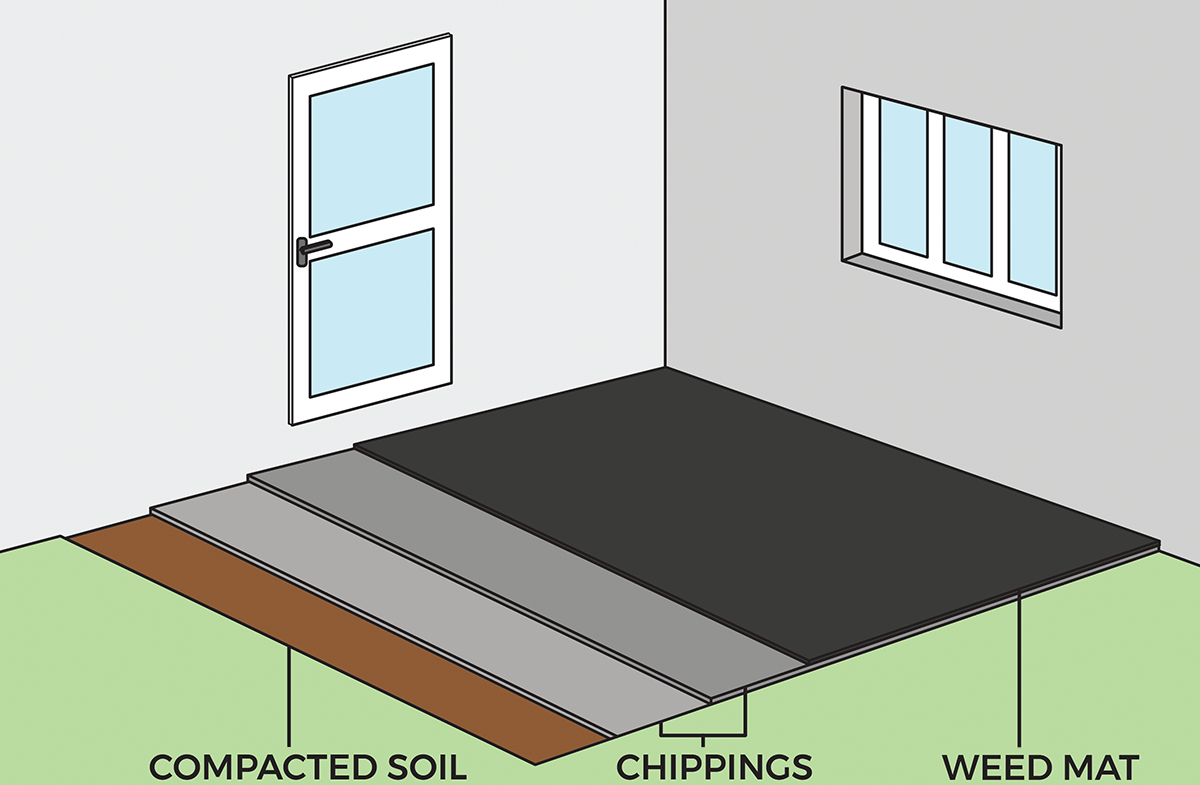

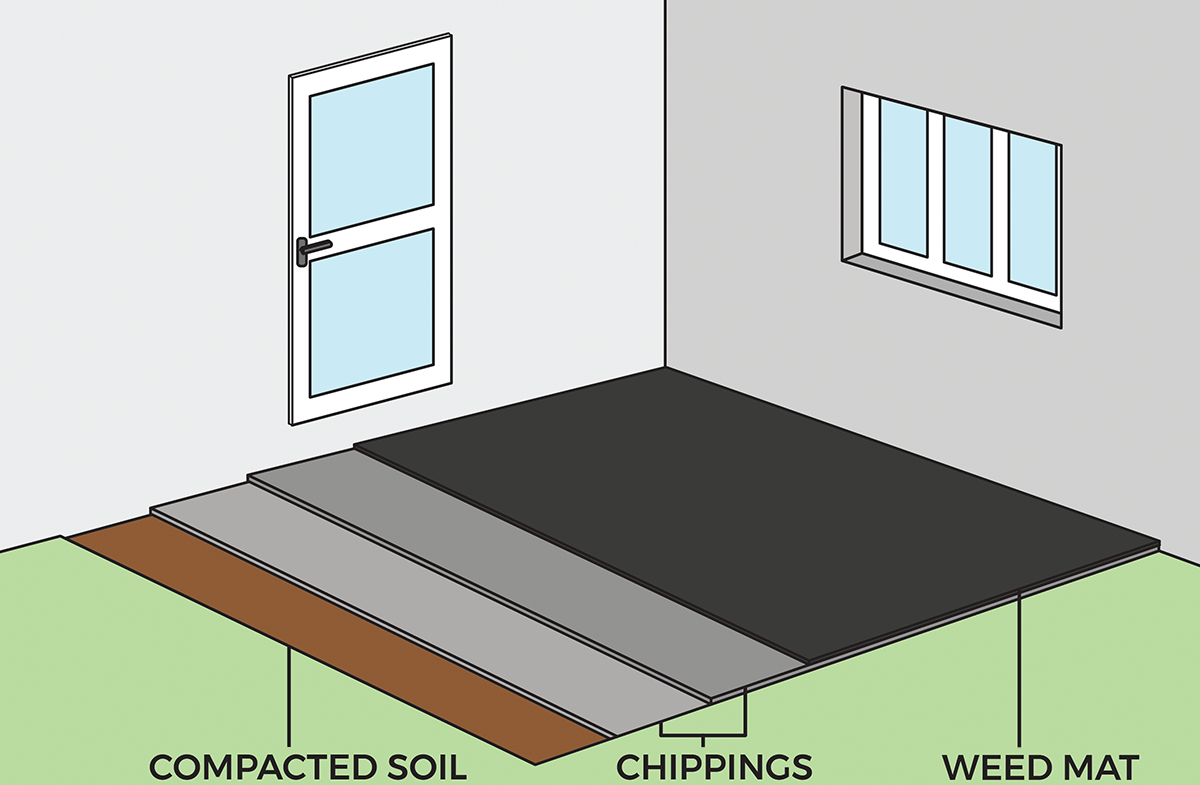

GRASS OR SOIL BASE

A grass or soil base must be excavated and prepared by removing unstable material, compacting the soil, and creating a firm foundation.

Build up a gravel bed with compacted chippings (around 5–10 cm) to provide a stable, load-bearing surface. For the top layer, add a further 3–5 cm of chippings, smoothed and levelled to maintain the required slope for drainage. A gentle slope of around 2% (approximately 2 cm per metre) away from the property will ensure effective rainwater run-off.

Finally, lay a weed-barrier membrane to prevent vegetation from growing between the decking boards once installed.

AIRFLOW

Ensure your substructure design allows for significant airflow and ventilation. If the decking is being installed in areas with poor ventilation, it must be installed on top of a substructure that allows for an airflow gap of 30mm.

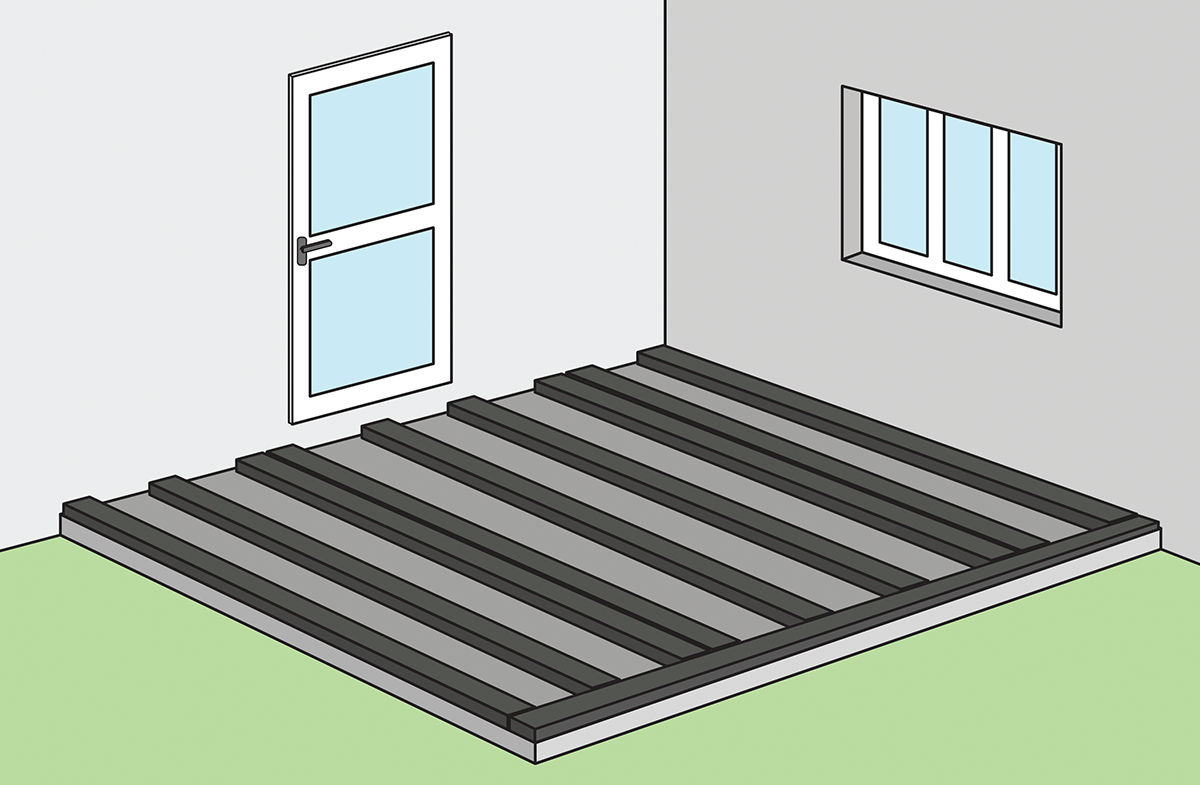

Subframe Installation

1

Mark out the decking area using stakes and a taut string line, ensuring a slope of at least 2% (around 2cm per metre) away from any building for drainage.

2

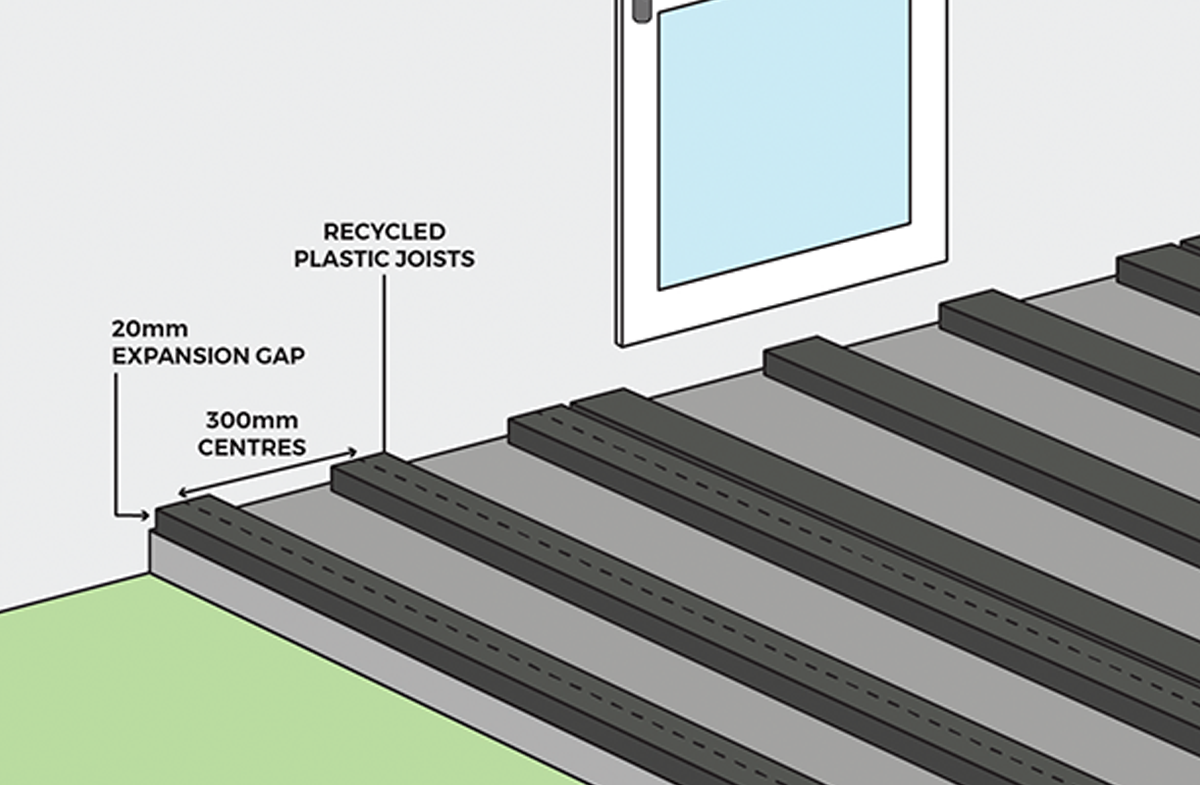

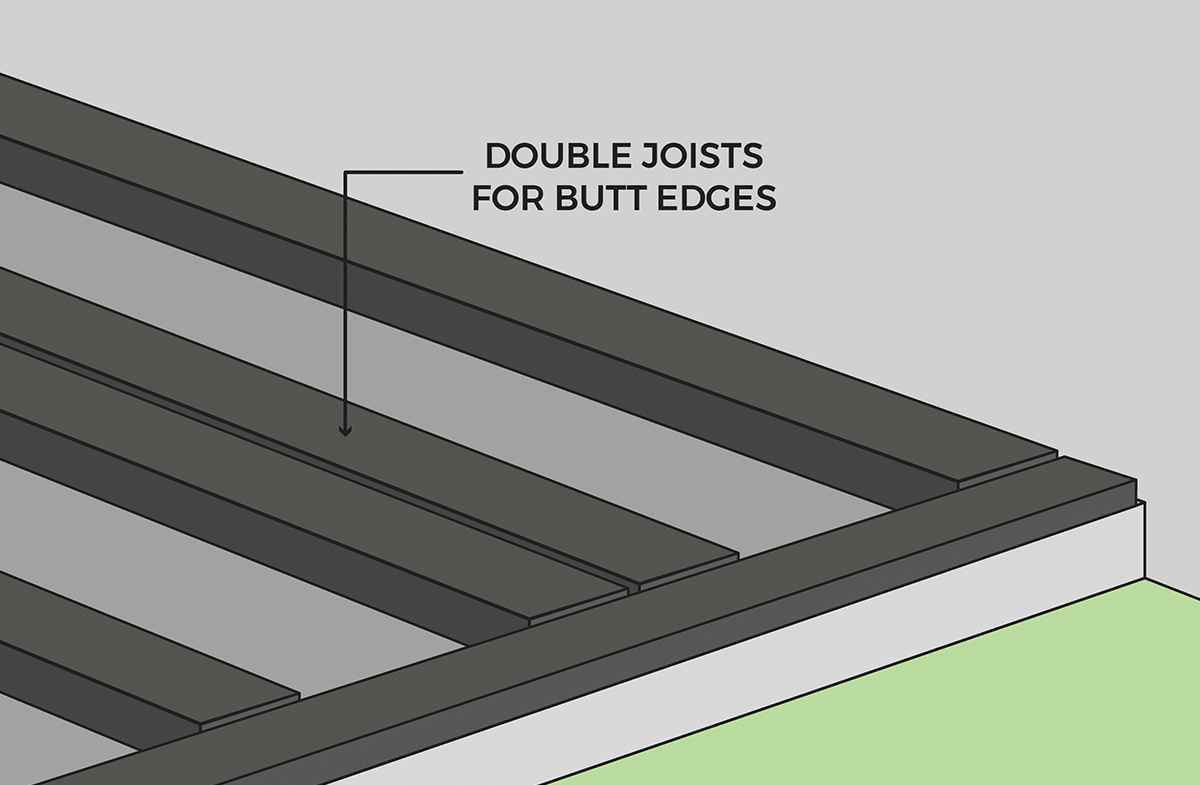

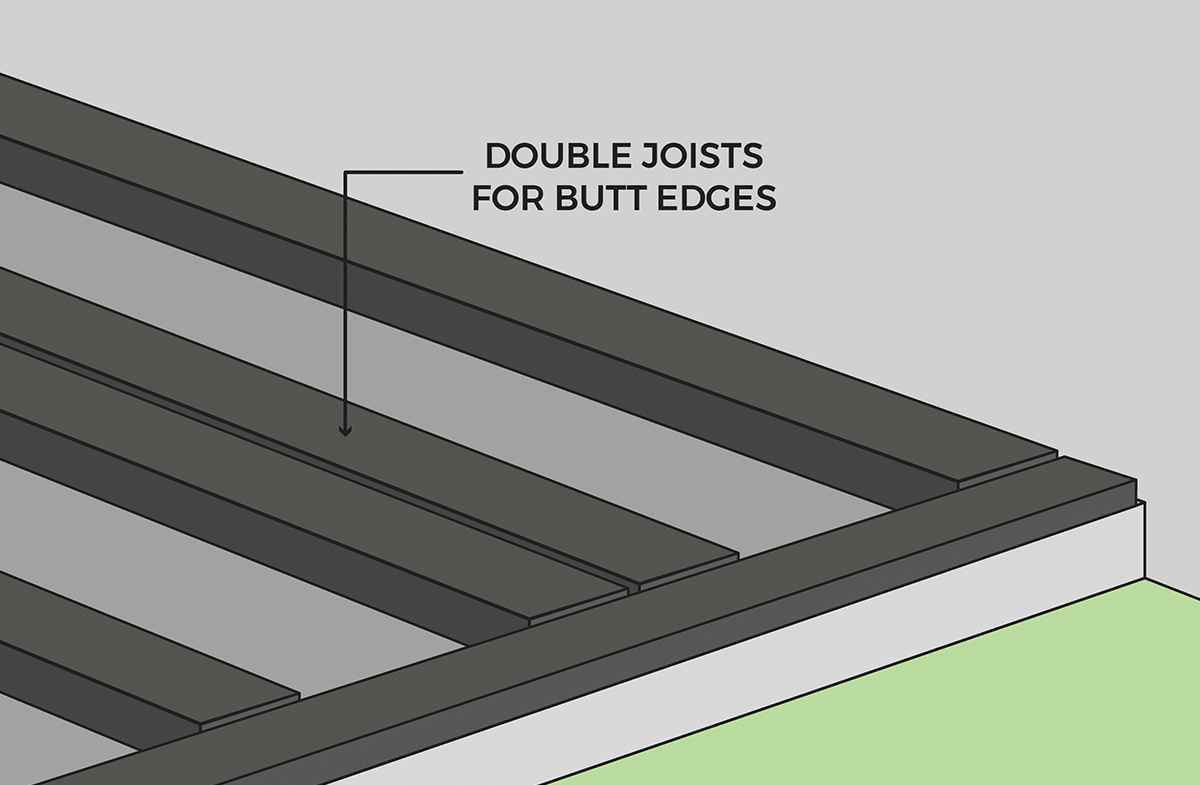

Lay your recycled plastic substructure joists (recommended dimensions approx. 50mm × 100mm) flat, never on edge, and space them at a maximum of 300mm centreto-centre.

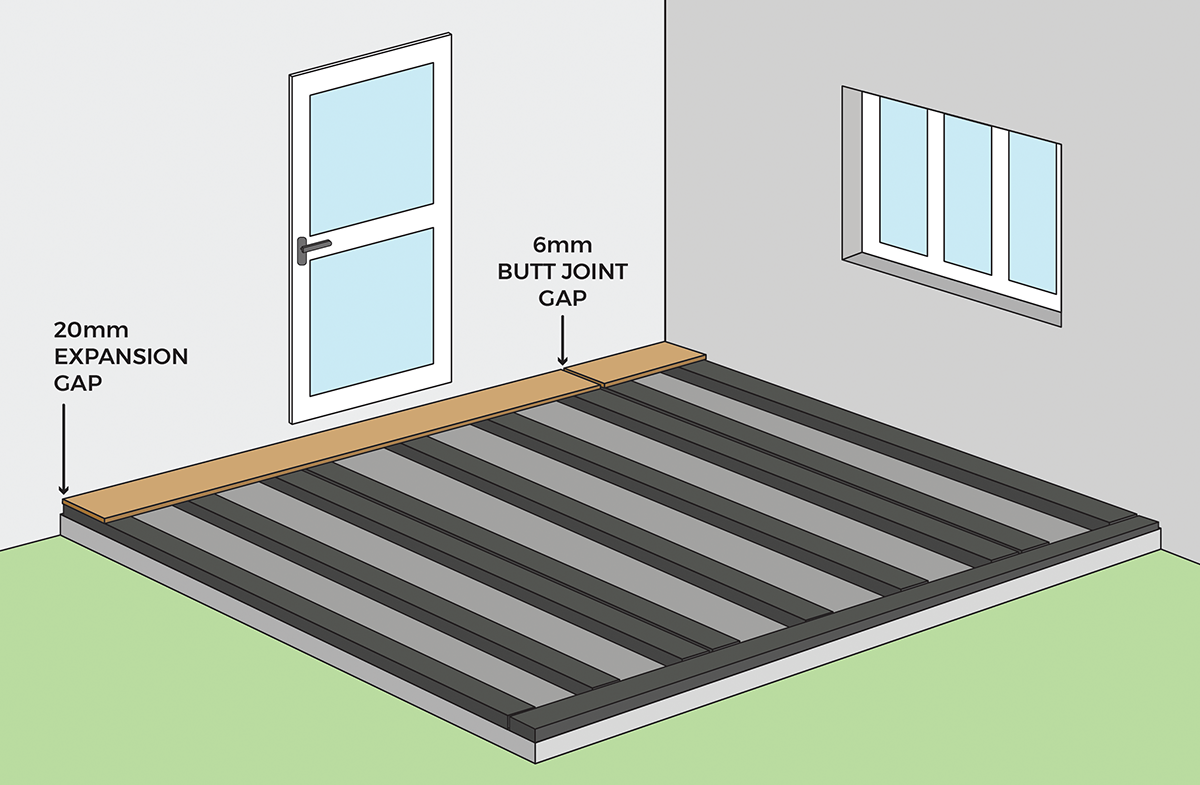

Leave a 20mm expansion gap between the subframe and any fixed boundaries such as walls or parapets.

3

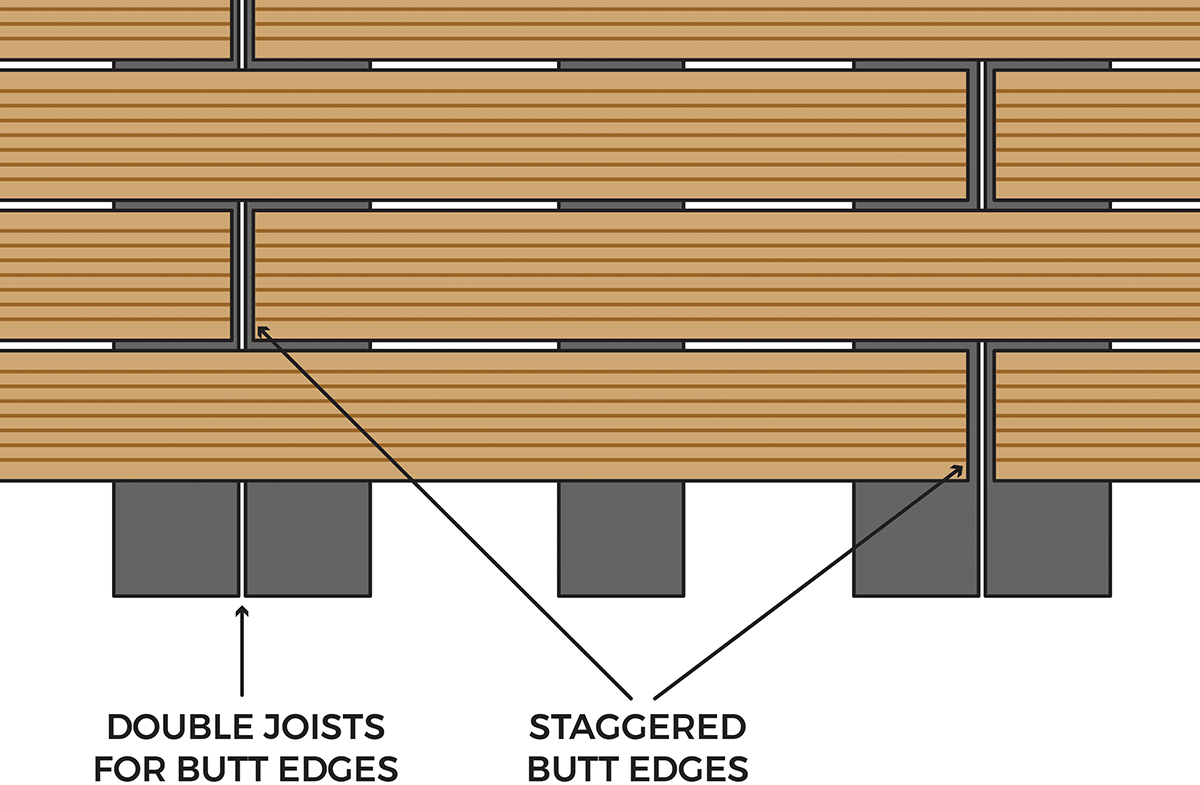

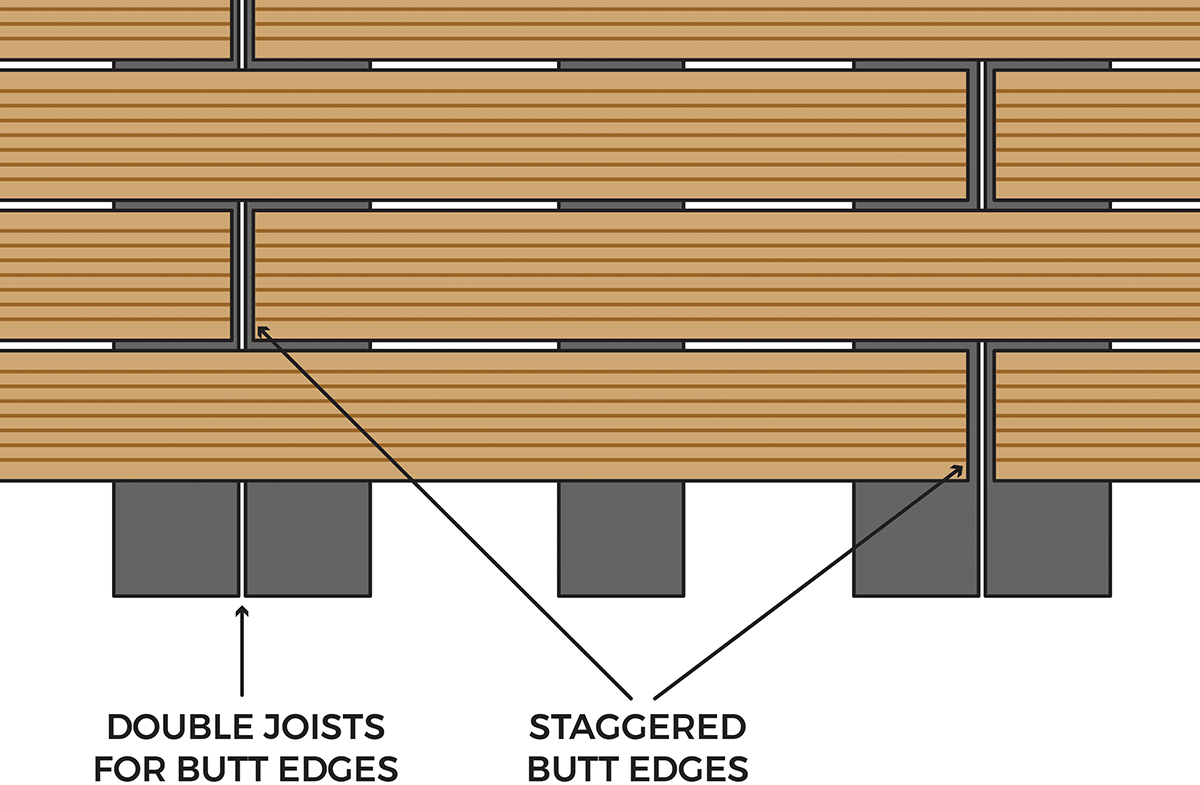

Stagger butt edges in the substructure so that board joints are properly supported, avoiding a single continuous line of joins. For larger areas exceeding 6m × 6m, divide the deck into separate modules with expansion joints.

SLIP-RESISTANCE

These recycled plastic decking boards have excellent slip-resistance in both dry and wet conditions. Even when installed on slopes up to 5°, the slip risk remains very small.

Laying the Decking Boards

1

Mark out the decking area using stakes and a taut string line, ensuring a slope of at least 2% (around 2cm per metre) away from any building for drainage.

2

Lay your recycled plastic substructure joists (recommended dimensions approx. 50mm × 100mm) flat, never on edge, and space them at a maximum of 300mm centreto-centre.

Leave a 20mm expansion gap between the subframe and any fixed boundaries such as walls or parapets.

3

Stagger butt edges in the substructure so that board joints are properly supported, avoiding a single continuous line of joins. For larger areas exceeding 6m × 6m, divide the deck into separate modules with expansion joints.

4

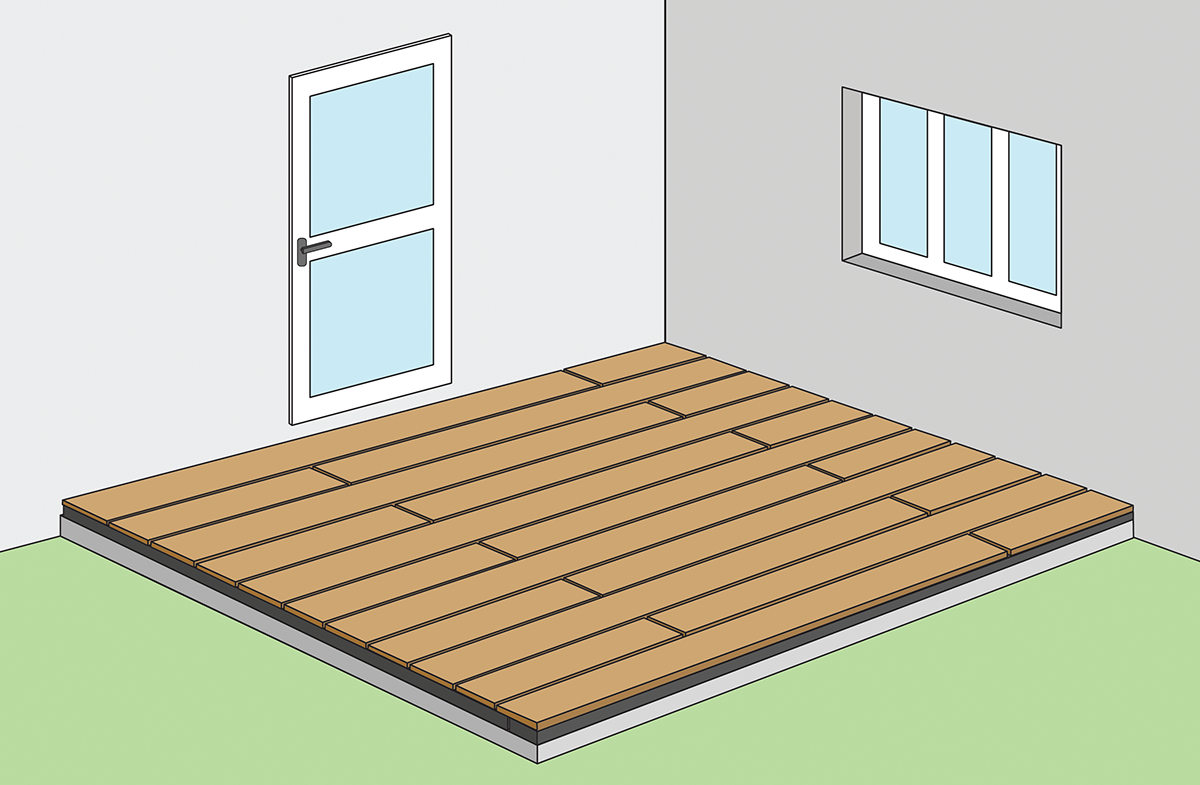

Continue to install the rest of the boards following the same method ensuring consistent spacing between boards. Check alignment regularly as you continue across the surface to maintain a straight, even finish until all boards are installed.

TIPS FOR FINISHING THE BOARDS

Finish exposed edges, end faces, and wall or boundary connections if desired. Options include curb stones or edge profiles which are screwed onto the decking boards.

When fitting edge materials, ensure that water cannot collect, and that expansion/movement of the decking boards is not restricted.

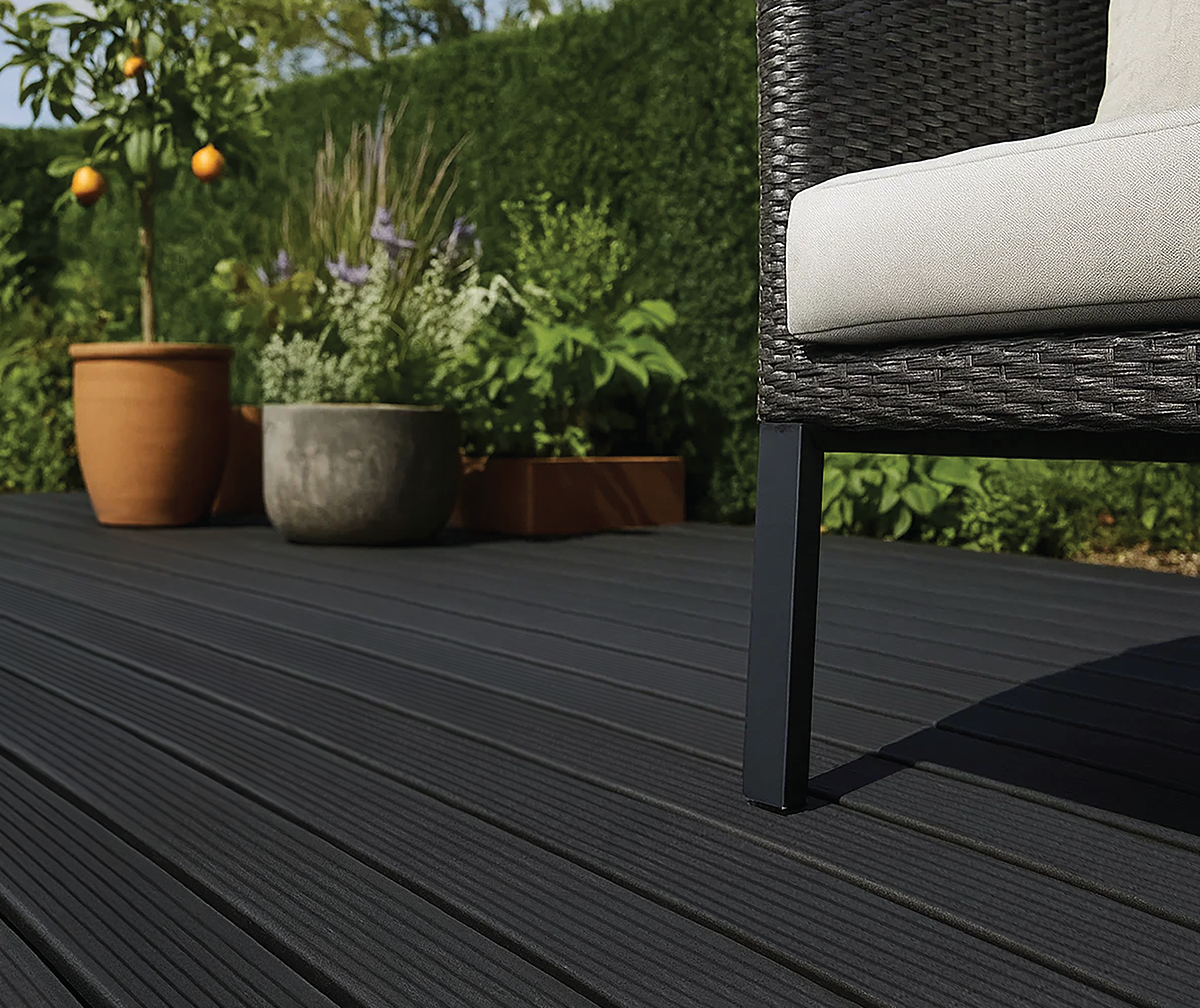

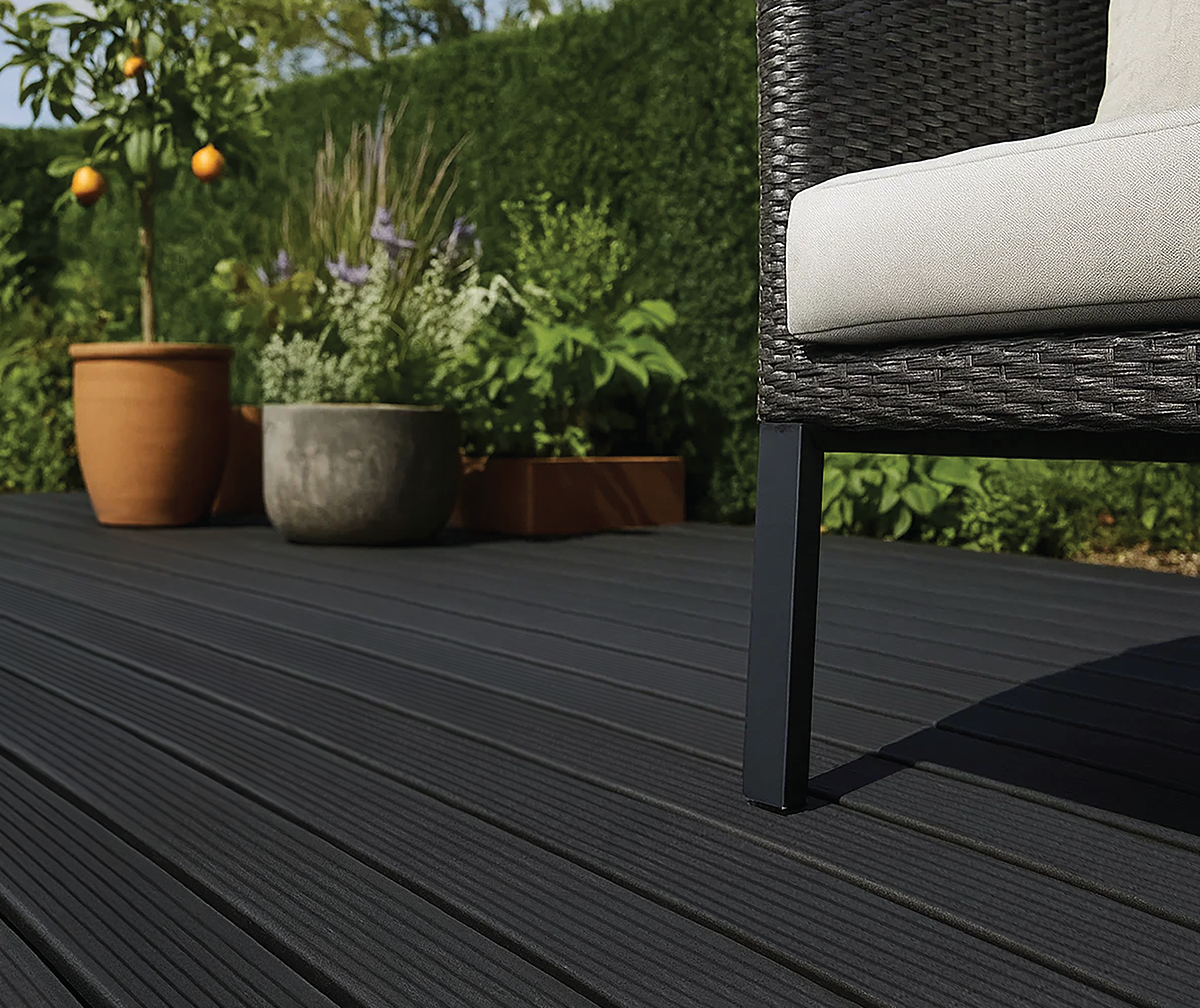

100% RECYCLED, 100% BUILT TO LAST

Made from 100% recycled plastic, these robust decking boards combine sustainability with strength and style. Resistant to water, frost, rot, and fungi, they won’t split or warp, even in areas prone to wet conditions. Subtle variations in colour and texture give each board a unique character, making them an ideal choice for gardens, terraces, parks, marinas, and public walkways where durability and low maintenance are essential.

Aftercare and Maintenance

MAINTENANCE

Recycled plastic decking requires very little upkeep, but regular care will help maintain its appearance and performance over time. Surfaces should be kept free of leaves, dirt, and debris to allow water to drain and air to circulate. Boards can be washed down with a mop, using clean warm water and mild household detergents as required.

All screws and fasteners should be checked periodically, and any that have worked loose must be retightened or replaced. The drainage slope should remain clear at all times to ensure effective water run-off, and boards should not be obstructed by soil, mulch, or plant growth.

It is also important to maintain the expansion and ventilation gaps around the decking. These spaces allow for natural thermal movement and must not be restricted by objects, edging, or vegetation. While the boards will not rot and require no surface treatments, routine inspection and basic cleaning will help ensure reliable long-term performance.

Frequently Asked Questions

Will my recycled plastic decking rot or need treatment?

No. Unlike timber, recycled plastic boards will not rot and require no surface treatments. With routine inspection and cleaning, they will provide long-term performance.

Do I need to prepare a base before installing the decking?

Yes. The surface must be load-bearing and frost-proof. On concrete, ensure there is a 2% slope (around 2cm per metre) for drainage. On grass or soil, excavate and build a compacted gravel bed with a weed-barrier membrane.

Will recycled plastic decking look the same over time?

Because the boards are made from recycled plastic, slight colour variations and surface differences are natural from the start. These differences are part of the material’s character and don’t affect performance. The colour is consistent throughout the board, so unlike timber, there’s no surface treatment or coating that can wear away.

How far apart should the subframe supports be?

Recycled plastic joists should be laid flat at a maximum spacing of 300mm centre-to-centre to give the boards the right level of support.

Do I need to leave gaps between board ends?

Yes. A minimum 6mm gap must be left at butt joints to allow for thermal expansion and movement.

What are these boards made of?

The boards are manufactured from 100% recycled plastic, giving them a strong, durable structure. Because of this, you may notice small variations in colour, surface texture, or dimensions of up to ±3%, which are completely normal and part of the material’s character.

What is it resistant to?

Recycled plastic decking is designed to perform outdoors in all weather conditions. It is water-resistant and frost-resistant, meaning it won’t absorb moisture or be damaged by freezing temperatures. The boards do not split or warp, even after years of use, and are naturally resistant to rot and fungi. This makes them a durable, long-lasting choice compared with traditional timber decking.

What is the slip resistance of recycled plastic decking?

Recycled plastic decking has excellent slip resistance. In independent testing (using the British Pendulum Test, BS EN 16165:2021 / ASTM E303-22), samples of three surfaces (INT027, RBU040, RGU050) produced median values of around 69-86 PTV/BPN in dry conditions, and 49-68 in wet conditions. All showed low slip potential in both dry and wet conditions. Even when installed on slopes up to 5°, the slip risk remains very small.

Can I use a jet washer to clean the boards?

Yes, recycled plastic decking can be cleaned with a jet washer. For best results, use a medium pressure setting and keep the nozzle at a sensible distance from the surface to avoid marking the boards. Regular cleaning with a mop, warm water, and mild household detergents is also effective for day-to-day upkeep.

Can I cut boards to size?

Yes, the boards can be cut down to the required length using an electric saw with a fine-toothed blade. Cut ends can be chamfered or rounded off if desired for a smoother finish. However, the boards must not be cut lengthways, as this would compromise their strength and stability

Where can recycled plastic decking be installed?

Recycled plastic decking is highly versatile. It is well suited to domestic gardens and terraces, as well as public spaces such as parks, marinas, and walkways. Its resistance to water and frost also makes it an excellent choice for areas that are regularly exposed to wet conditions.

Which Nordeck colour caps should I use with recycled plastic decking?

To achieve the best possible match and keep fixings concealed, we recommend using Nordeck colour caps that correspond to the board colour. Use black Nordeck caps with black recycled plastic decking boards, cedar wood Nordeck caps with beige boards, and ash grey Nordeck caps with grey boards. As there is no suitable colour match for brown decking (the chestnut caps are not recommended), we suggest using alternative fixing methods instead.

What colours are available?

There are four colours available with our recycled plastic decking: brown, black, beige, and grey.