Cladco ProClad Composite Wall Cladding Installation Guide

Installation Guide, Aftercare and FAQS

Storage, Colour and Warranty

STORAGE AND HANDLING

Cladco ProClad composite wall cladding boards should always be stored in a cool shaded spot, on a flat and level surface which supports the whole length of the boards. It is recommended to store the boards on a pallet to ensure they are not sat directly on wet or cold ground. Boards should be stored properly until they are ready to acclimate prior to installation.

Wear protective gloves when handling the boards and take care when lifting them. We recommend that a minimum of two physically capable persons carry the boards. It is recommend that when cutting the boards, they are placed on a timber surface to prevent scuffing.

COLOUR AND GRAIN

Our ProClad boards are manufactured from capped composite materials and are designed to replicate the natural variations of a timber cladding board. Each board features an authentic woodgrain-effect textured surface and a unique multi-tonal colour blend for a natural-looking finish, ensuring no two boards are identical. It is, however, still recommended that you purchase all ProClad boards required for the same project together at the same time, as this will ensure colour consistency throughout – whilst saving any additional delivery costs. As with all materials exposed to direct sunlight, some natural weathering may occur over time. Boards should be acclimatised to the same temperature and stored in the same environment prior to installation.

Please be aware that the appearance of composite boards can change depending on weather conditions. When wet, the boards may display a different tone compared to when they are dry.

15 YEAR WARRANTY

Cladco ProClad cladding boards are supplied with a 15-year warranty, subject to terms and conditions. Cladco cladding boards should be installed as per this installation guide, and failure to do so may invalidate the warranty.

For further information, see our terms and conditions.

COLOUR VARIATION

To ensure a balanced and visually pleasing result, we recommend laying out all the boards before installation to evenly distribute the natural variations across your installation.

Tools and Equipment

PROTECTIVE EQUIPMENT

When handling or carrying cladding boards it is advised to wear long sleeves and gloves. When cutting the boards, we suggest wearing a protective dust mask, ear defenders and safety glasses.

TOOL SET

Standard everyday carpentry tools will be needed to complete the installation, including a tape measure, pencil and stanley knife.

POWER DRILL OR DRIVER

Standard power drills can be used when installing ProClad wall cladding boards.

JIGSAW OR HANDSAW

ProClad wall cladding boards can be cut using any standard wood cutting tools. We recommend using a fine-toothed blade to get the cleanest finish to your cut edge.

SPIRIT LEVEL

A spirit level is essential when installing your battens to ensure a level support system.

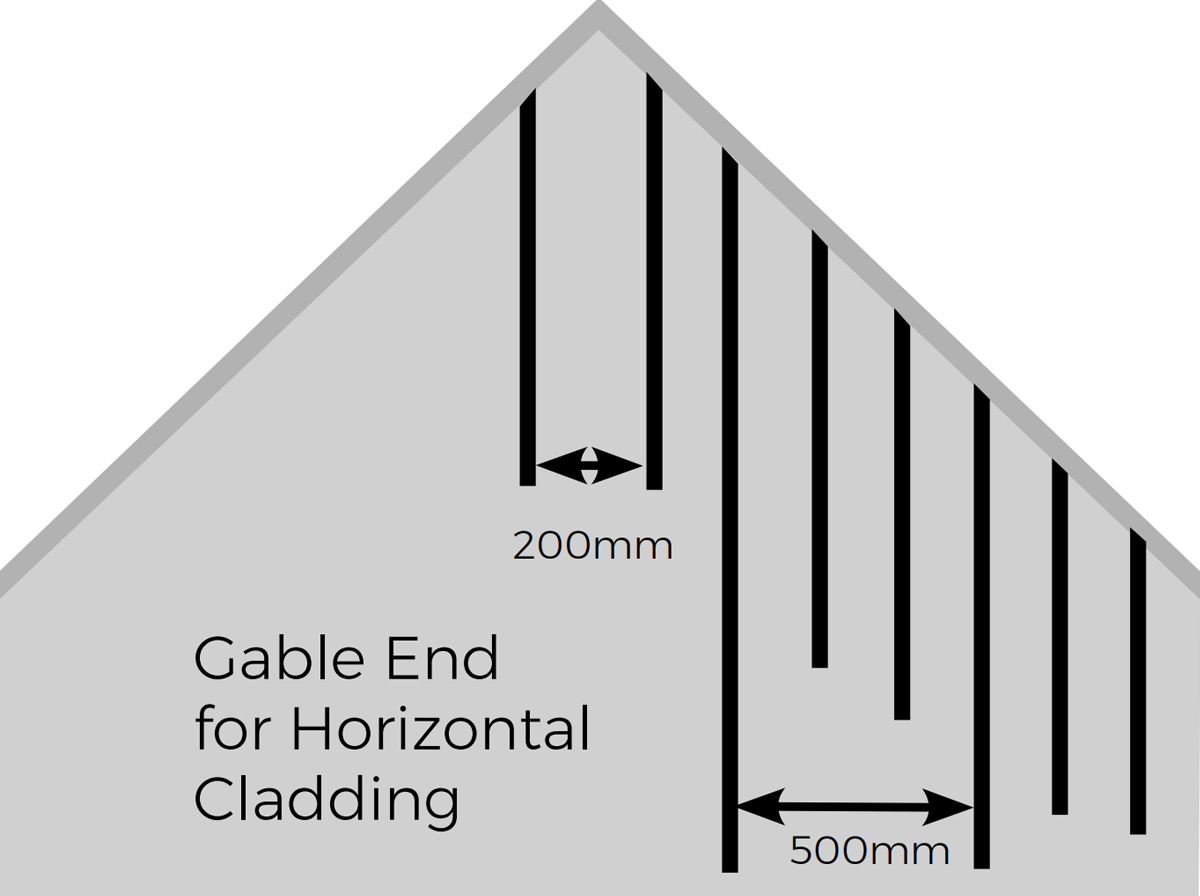

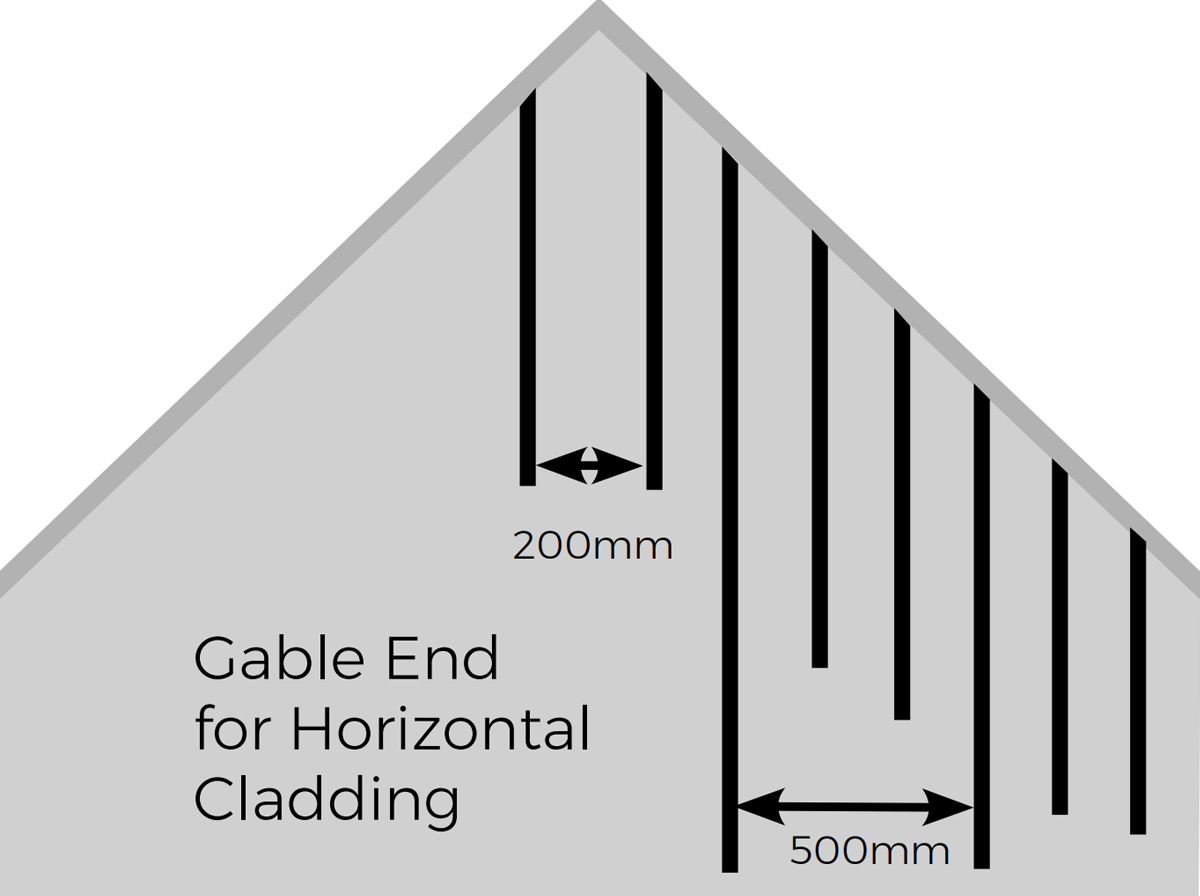

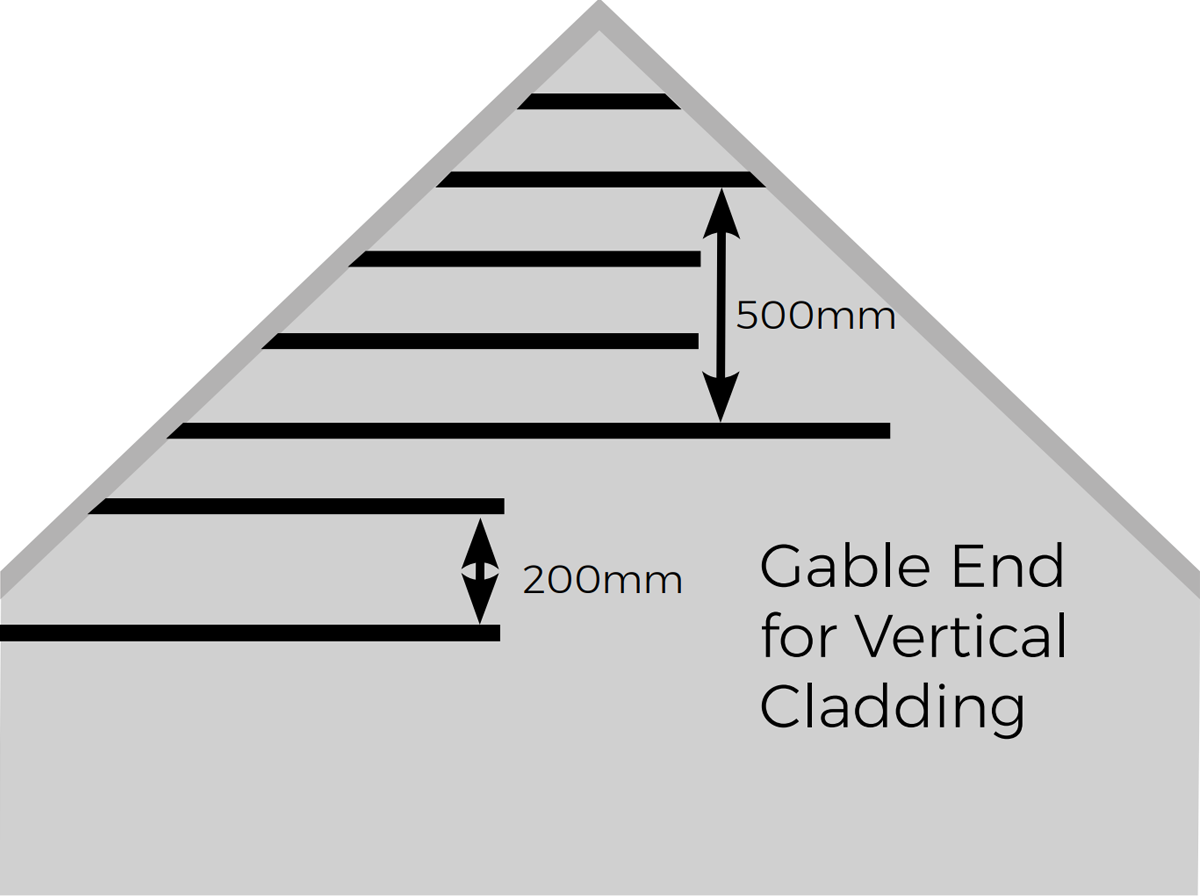

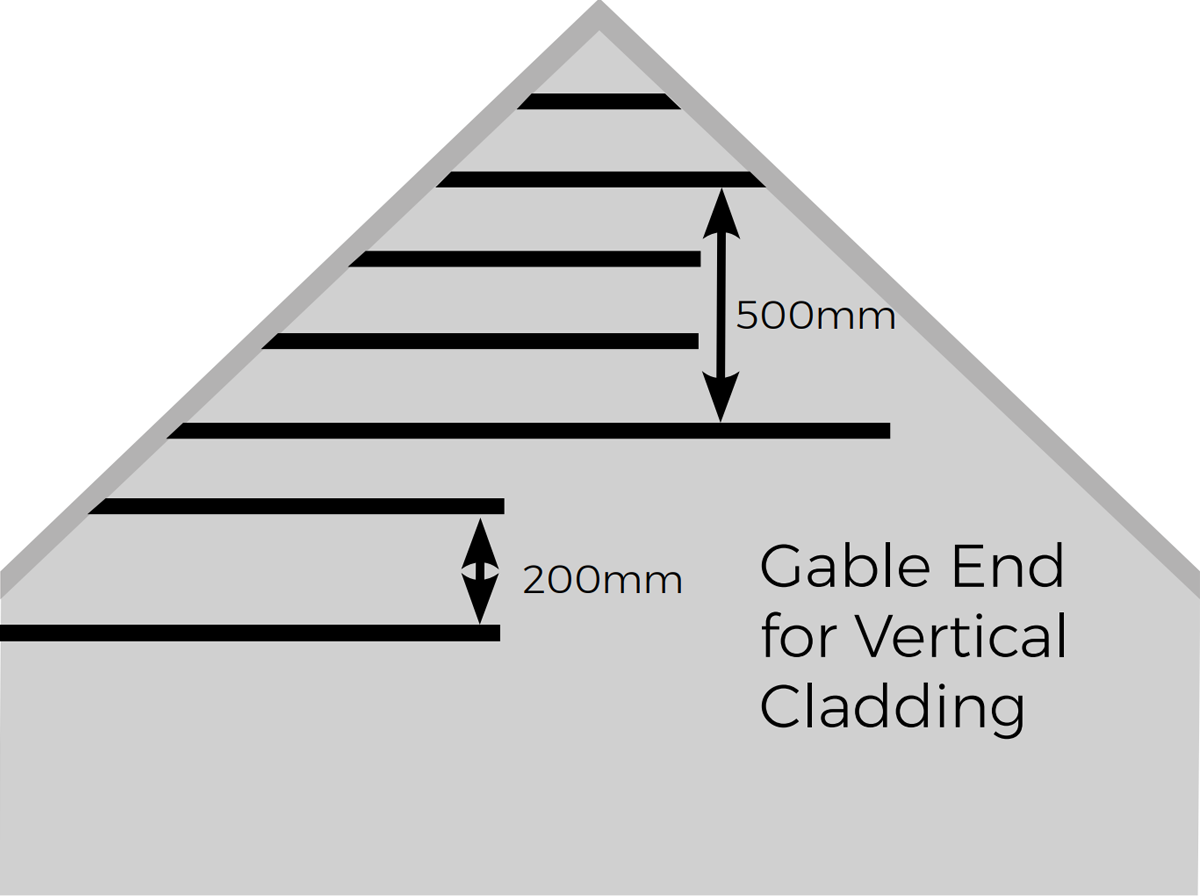

Preparing a Gable End

If your home has a gable end, battens must be spaced up to 500mm apart, with additional, shorter supporting battens installed every 200mm, going up and down the apex (the triangular shape of your gable end). This ensures that the ProClad boards are fully supported across the entire build.

Ensure all battens are level using either a tape measure or a spirit level before installing boards. When installing 30mm x 50mm composite battens flush to the wall, be sure to leave an adequate ventilation gap between the wall and the ProClad boards to allow air to flow. Check your wall is stable and secure before pre-drilling 6mm holes.

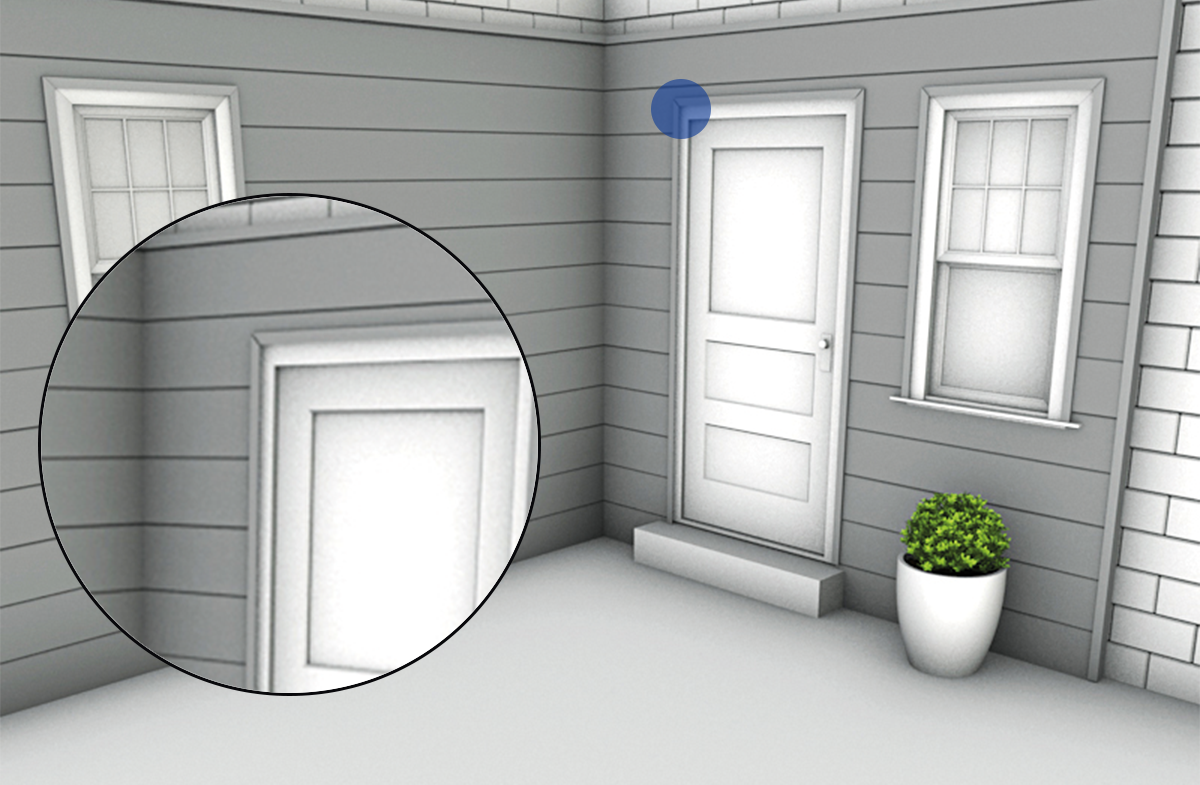

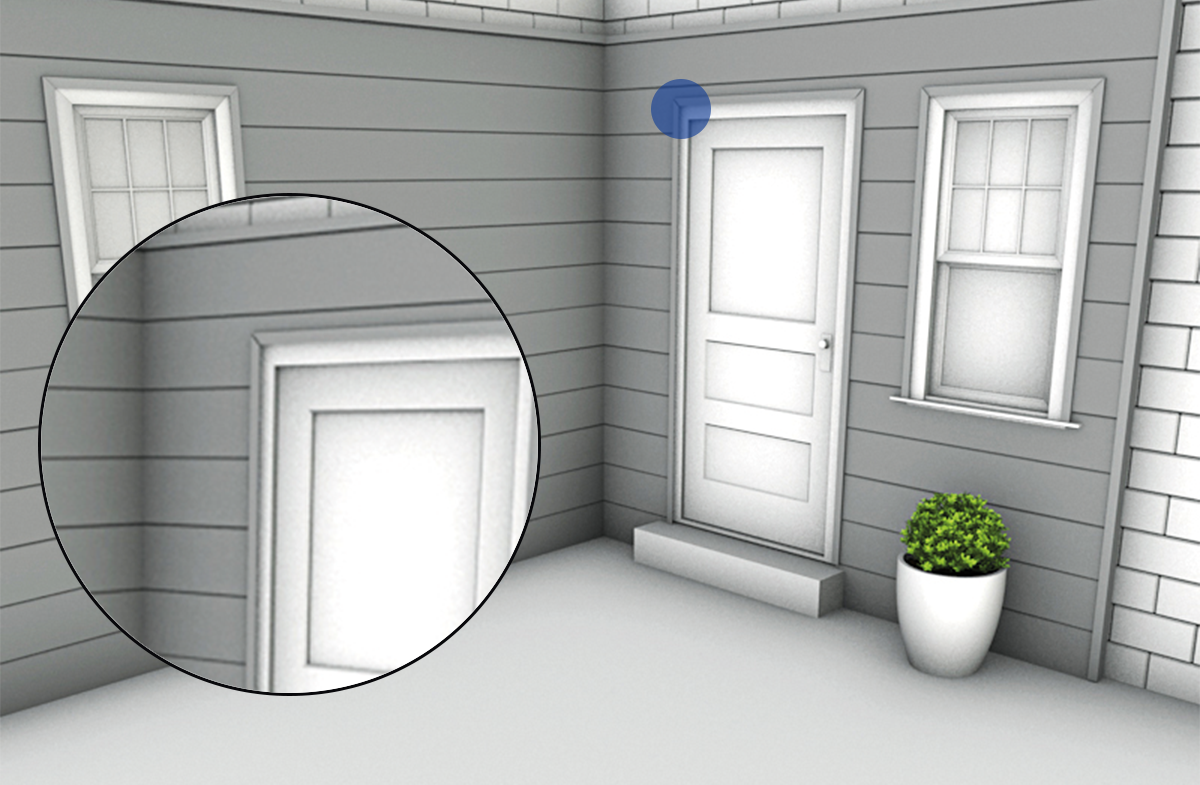

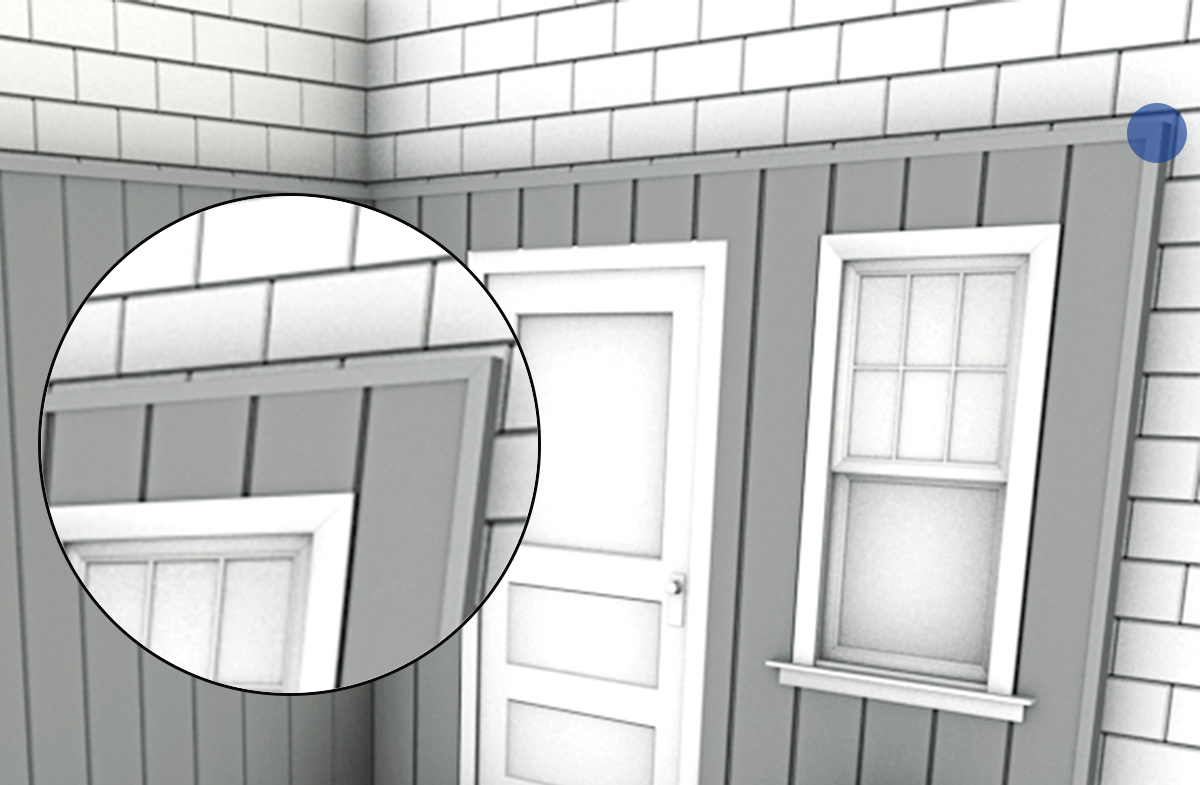

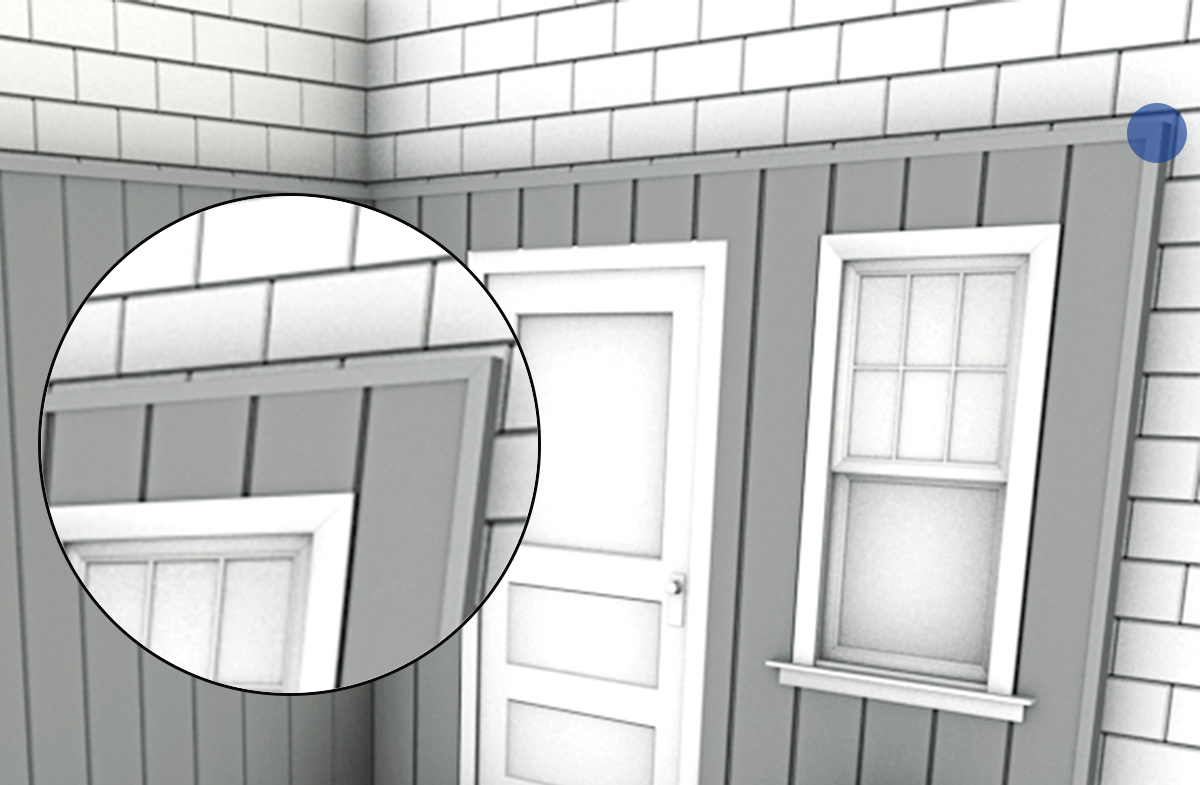

DOORS AND FIXTURES

Thanks to the flexibility of ProClad boards, exterior fittings such as lights can be installed just as easily as they would be with traditional timber cladding.

ProClad boards and ProDeck corner trims can be easily cut and adjusted around wall fixings, doors, and windows using standard woodworking tools. This makes it simple to incorporate additional features—like exterior garden lights—into your design for a clean, professional finish.

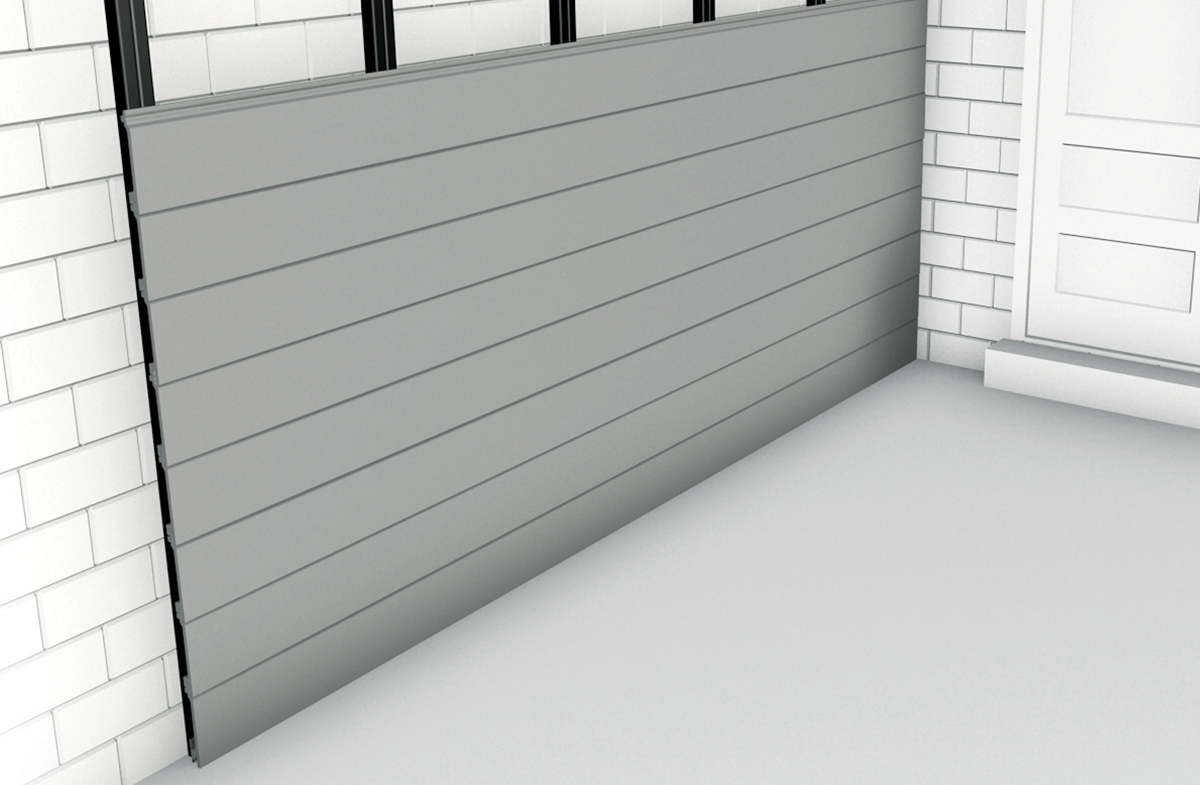

Installation - Horizontal

1

Pre-drill the battens and the surface below using a 6mm drill bit. The battens are 30mm high and should be secured at least 50mm into the surface. Choose fixings that are appropriate for the material you’re working with— screws should be 5–6mm in diameter and at least 80mm long*.

*Cladco does not provide the fixings and screws for your installation.

2

Battens should be attached to the surface at a maximum distance of 500mm apart. The battens will need to run the entire length of the area being clad, adding in additional battens at any point where you will need to join two cladding boards end to end. Remember to install your battens at a 90° angle to the way that you want your wall cladding boards to run. Battens should be 50mm wide x 30mm high and should be fully supported once installed. It is important to ensure the surface below the battens is flat and stable.

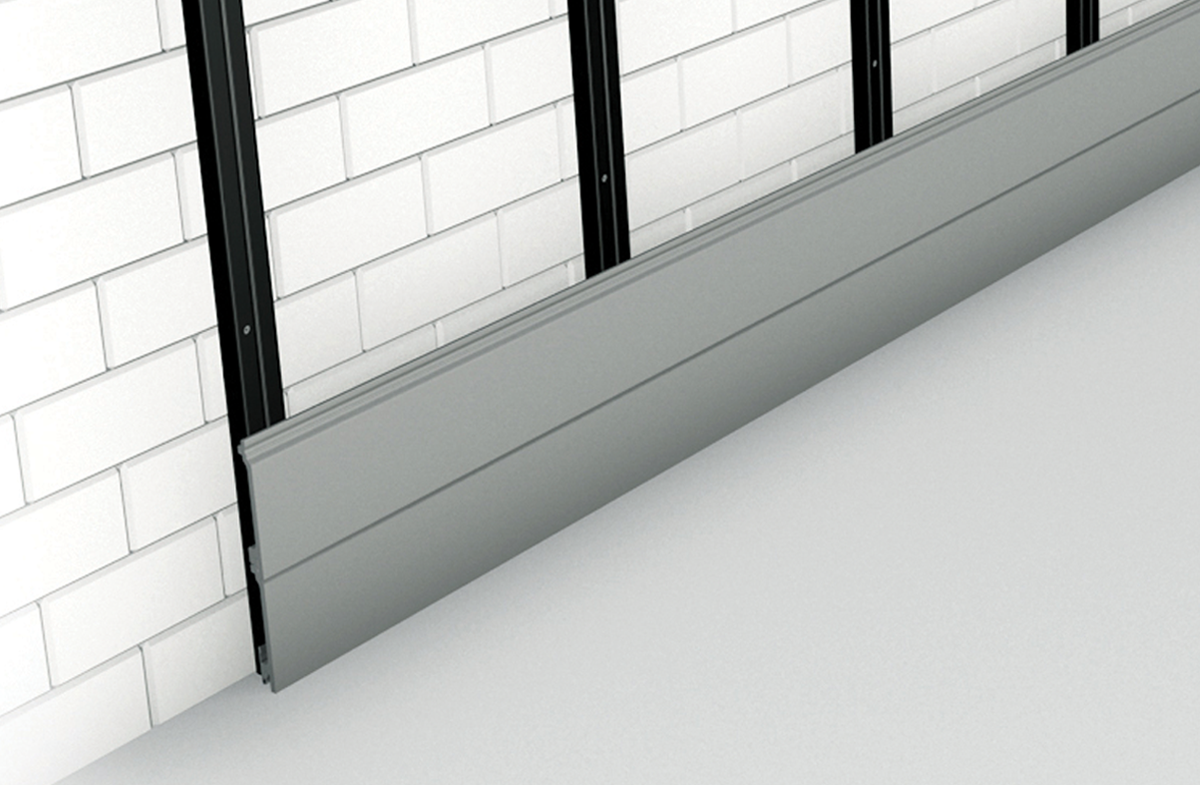

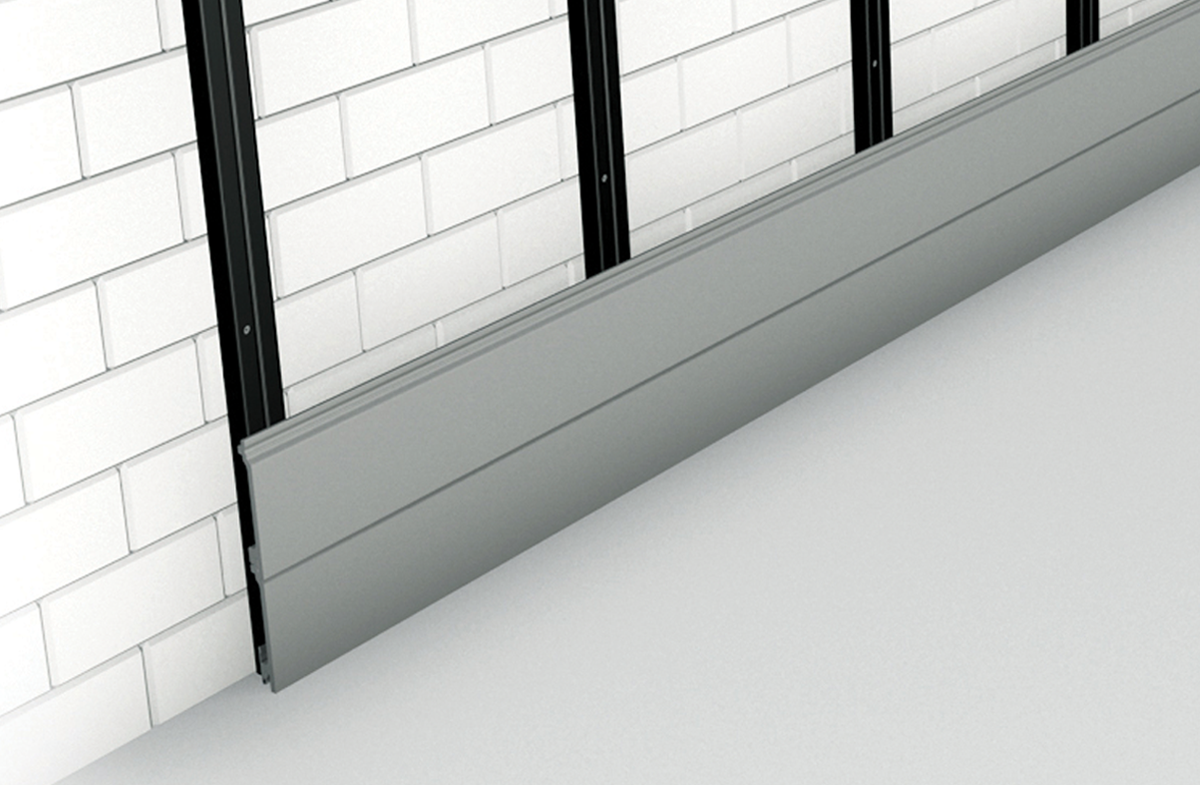

3

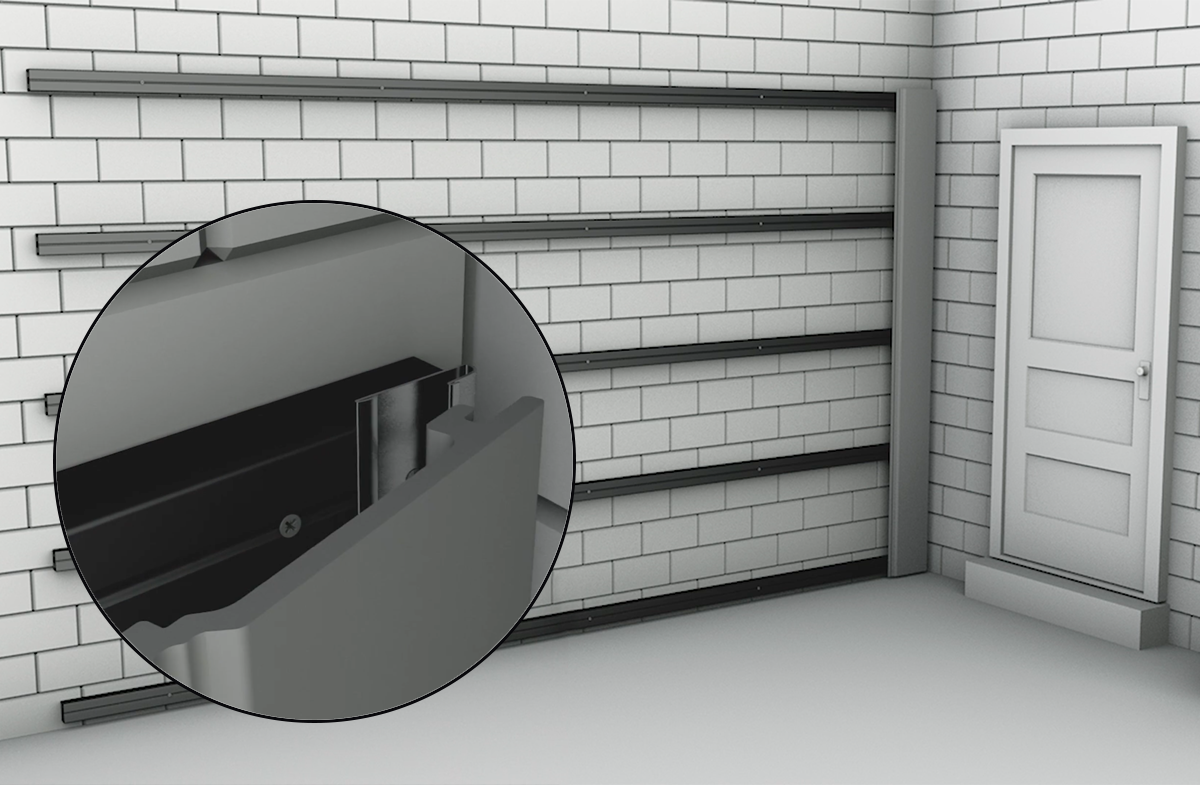

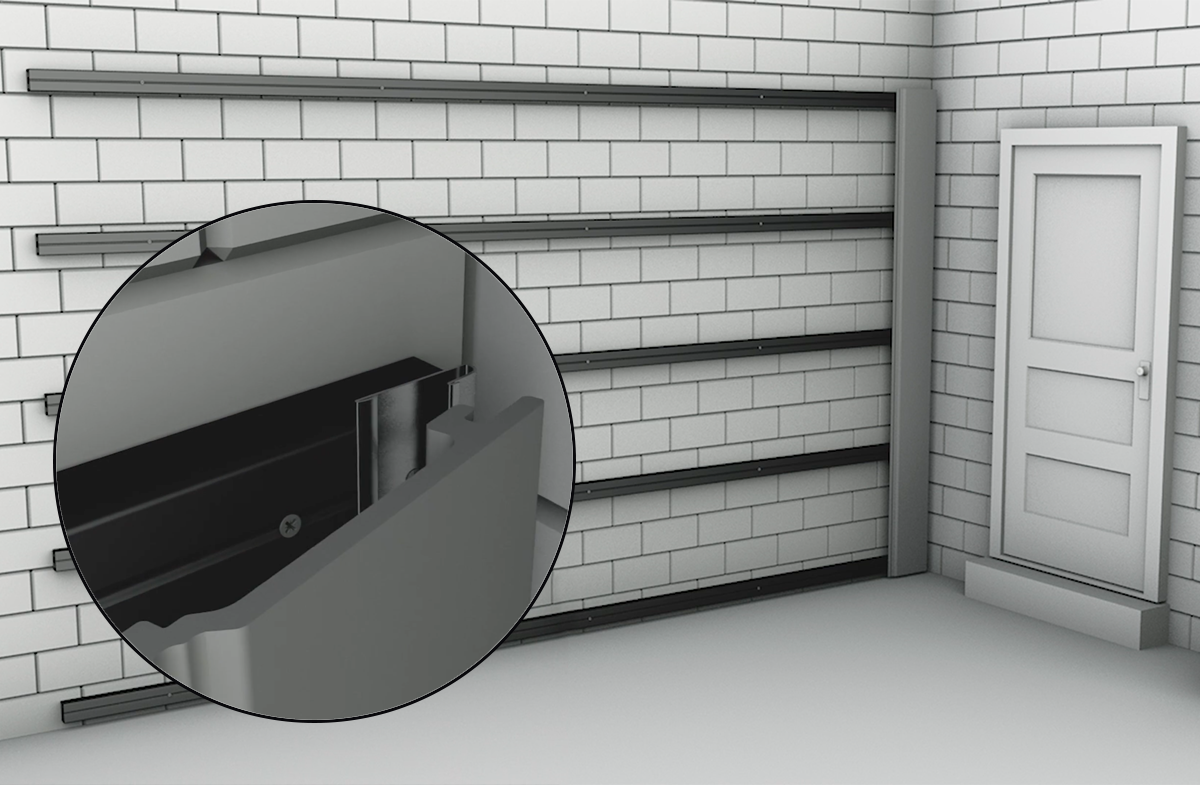

Attach a starter strip to the bottom of each batten, leaving a 10mm ventilation gap at the base of the installation. Ensure no sealant is applied around this area. This will give the first cladding board something to sit on. You will need to pre-drill a pilot hole into the composite batten and attach the starter strip using a screw that is at least 15mm long. Ensure that each strip is level with the next and that the first board sits level on the strips before continuing to the next step.

EXTREME TEMPERATURES

Extreme temperature changes could cause the boards to expand or contract. Ensure boards have had sufficient time to acclimatise to the temperature before installing. Do not install in extreme temperatures.

CUTTING

If boards need to be cut to size, ensure the boards are installed and secured immediately after cutting.

4

Place the first wall cladding board onto the starter strips. Mark and then pre-drill pilot holes through the fixing groove of the board into the batten below. Secure the boards using a screw at least 20mm in length, ensuring that the board is fastened securely on each batten that it touches. Secure these fixings by hand, as it is important not to over-tighten the screws and risk splitting the board.

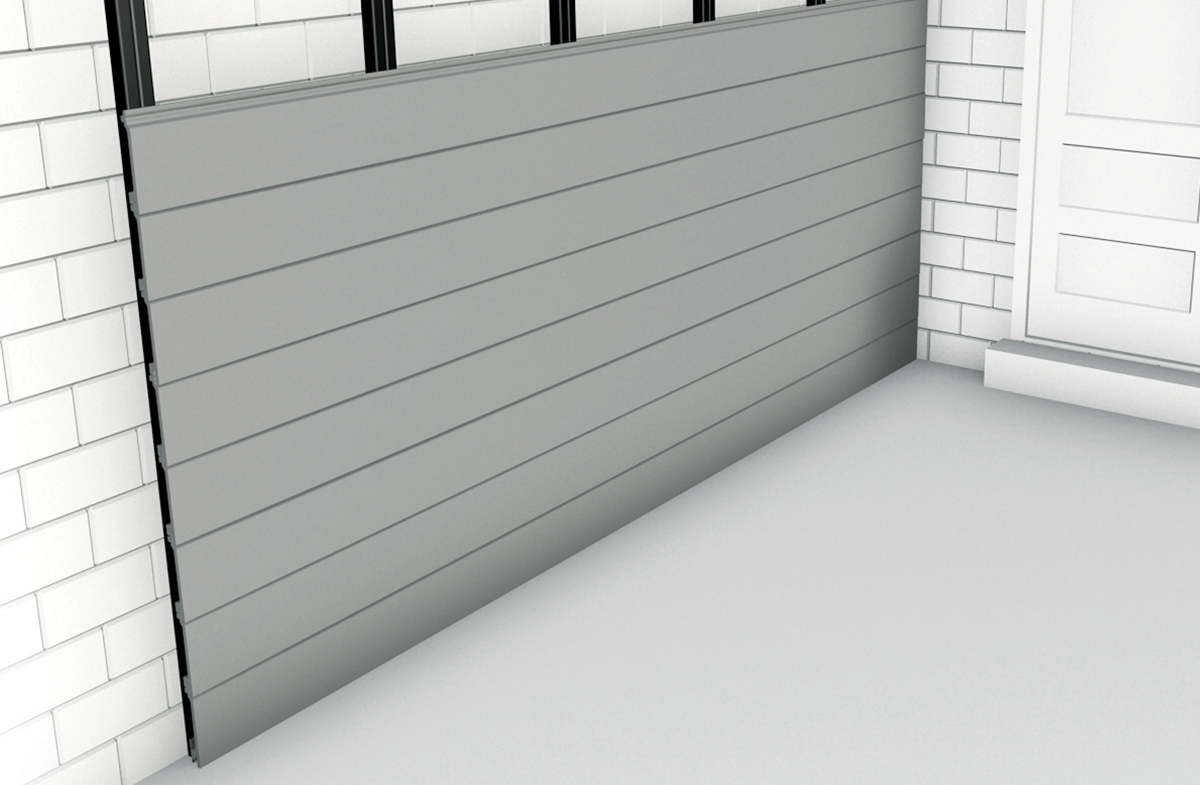

5

Slot the second board onto the first and repeat the fixing process, making sure it is securely fitted to each batten. Continue this method with each subsequent board until you reach the required height. Be sure to leave the sections between the battens empty to allow proper airflow beneath the boards.

6

When butting two boards together, you should use a mitred edge for a neat finish. The most common mitre angle is 45°. As the cuts are angled, you’ll have one side of the wood longer than the other. You’ll need to keep track of which side will be which and make your measurements correctly.

7

Set the mitre saw to the angle it will need to cut. Use the included instructions for your machine, as each is different. Set the pieces side by side to ensure a neat joint. Screw the wall cladding board through the top and into the batten.

8

Continue to fit the cladding boards in this manner until you have completely covered the area you want. It is possible to fit your boards side by side by simply butting the two ends up together and allowing for a temperature expansion gap. You may need to install more battens if you wish to do this, as each board will need to be supported on a batten where it meets the next board.

WOODGRAIN EFFECT CLADDING

ProClad capped composite wall cladding features an authentic woodgrain-effect finish, available in seven multi-tonal colours that replicate the natural look and texture of timber.

Enhance the exterior of your home or commercial property with ProClad’s durable, low-maintenance boards—designed to create a sleek, contemporary finish that complements or contrasts your building’s style.

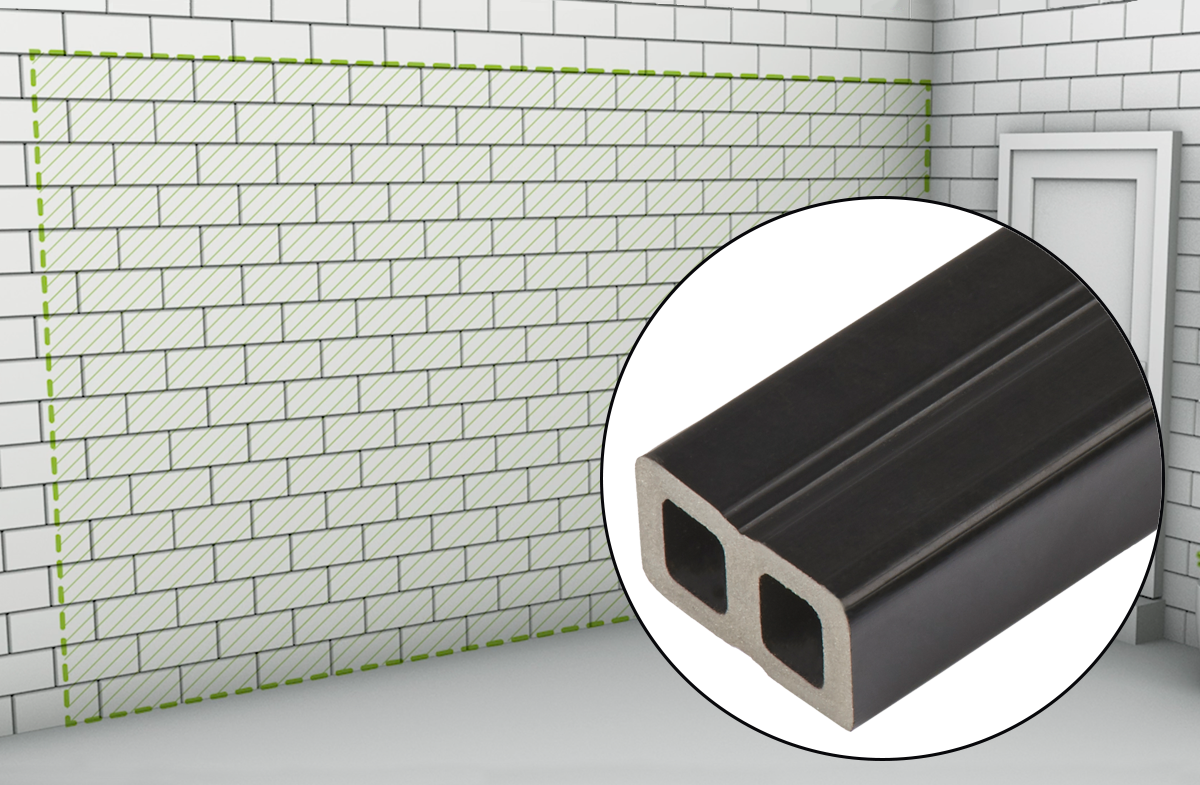

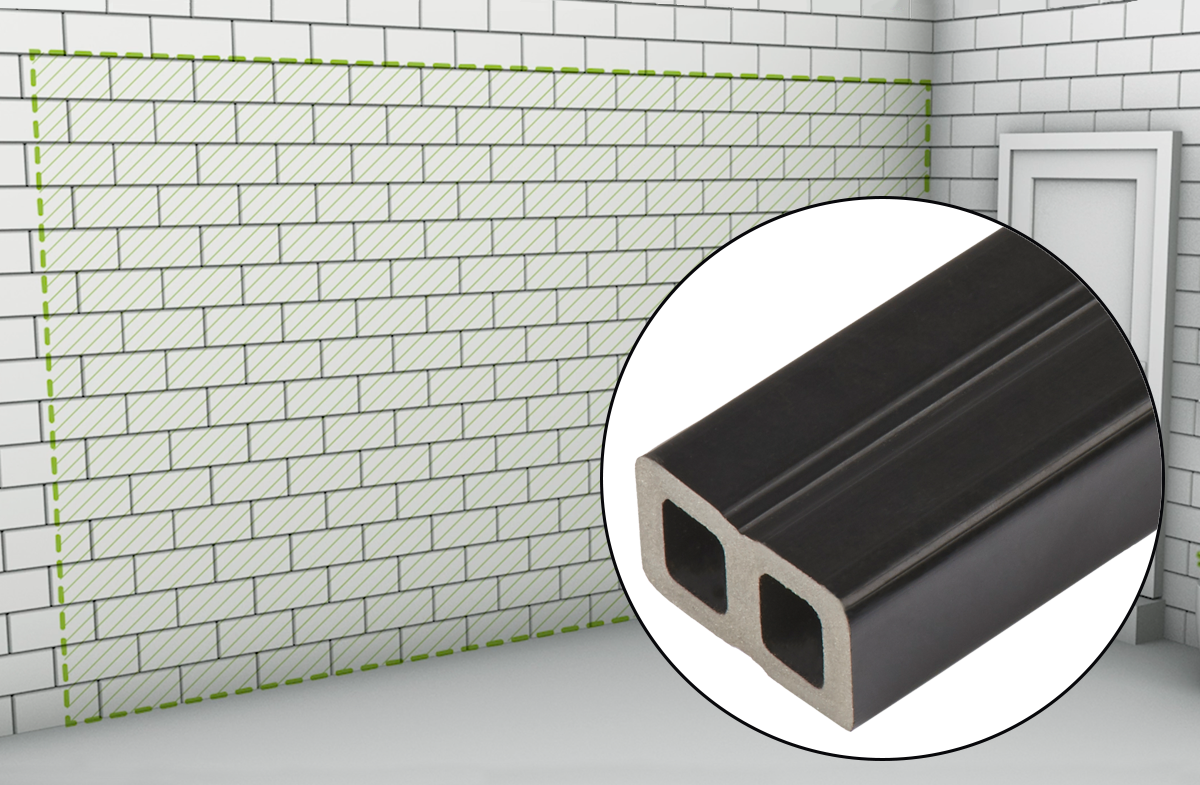

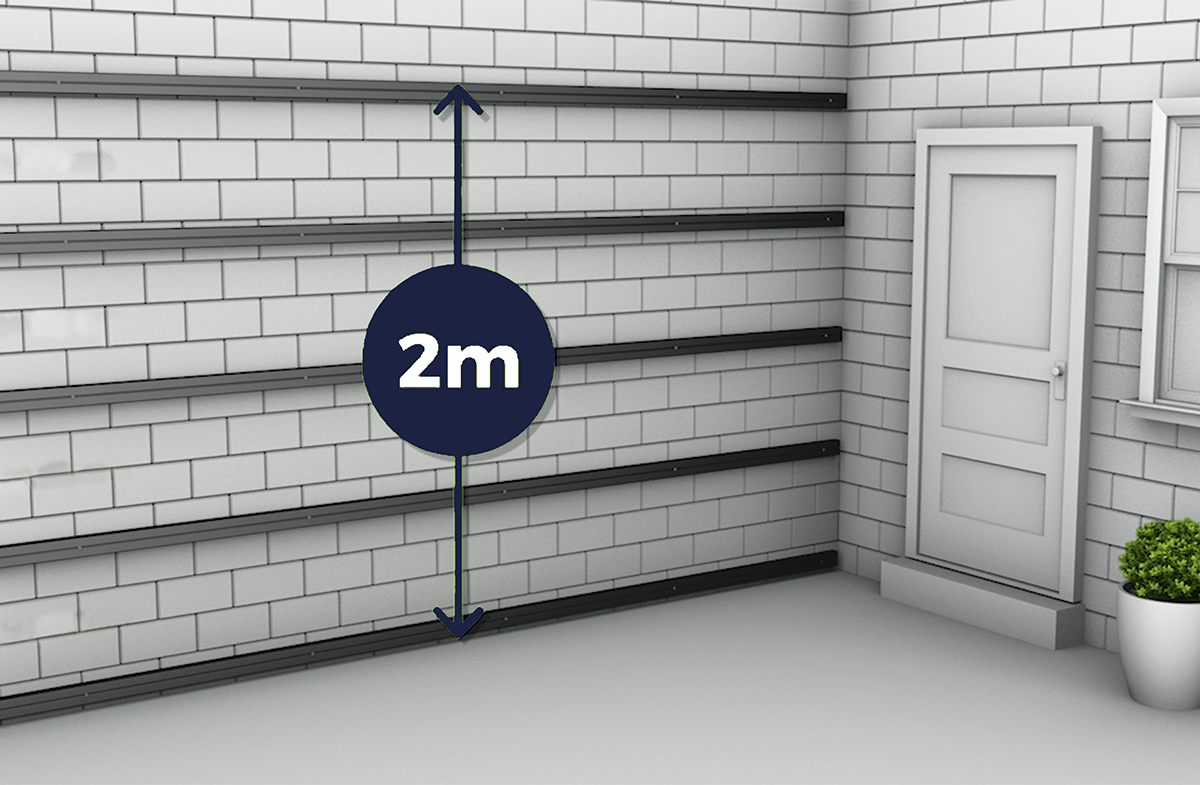

Installation - Vertical

1

We recommend the battens used to support your ProClad composite wall cladding boards are made from a composite material, as this helps to maximise the long-term performance of your cladding. Alternatively, you can use wooden battens to support your cladding following the same fitting process as you would for composite battens.

2

Pre-drill both the battens and the surface below using a 6mm drill bit. Cladco composite battens are 30mm high and should be secured at least 50mm into the underlying surface. Be sure to select fixings appropriate for the material you’re drilling into. Screws should be 5–6mm in diameter and a minimum of 80mm in length*.

*Cladco does not provide the fixings and screws for your installation.

3

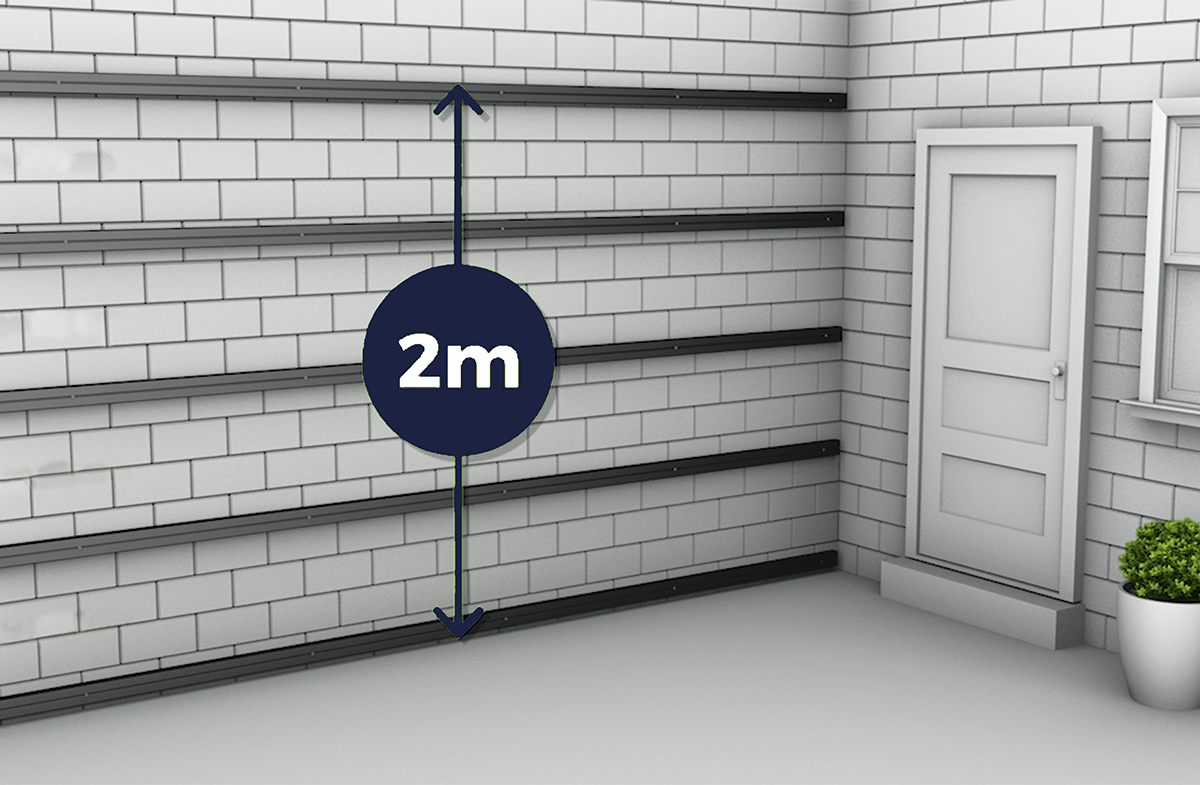

Battens should be fixed to the surface no more than 500mm apart. They must span the full length of the area being clad, with additional battens installed wherever two cladding boards will be joined end to end. Ensure the battens are mounted at a 90° angle to the direction you intend the cladding boards to run. It’s also essential that the surface beneath the battens is flat and stable to guarantee a secure installation.

EXTREME TEMPERATURES

Extreme temperature changes could cause the boards to expand or contract. Ensure boards have had sufficient time to acclimatise to the temperature before installing. Do not install in extreme temperatures.

CUTTING

If boards need to be cut to size, ensure the boards are installed and secured immediately after cutting.

4

Attach a starter strip to the right side of each batten, as this will give the first cladding board something to sit on. You may wish to pre-drill a pilot hole into the composite batten and attach the starter strip using a screw that is at least 15mm long. Ensure that each strip is level with the next and that the first board sits level on the strips before continuing to the next step. Leave a 10mm ventilation gap at the side of the installation and ensure no sealant is applied around this area.

5

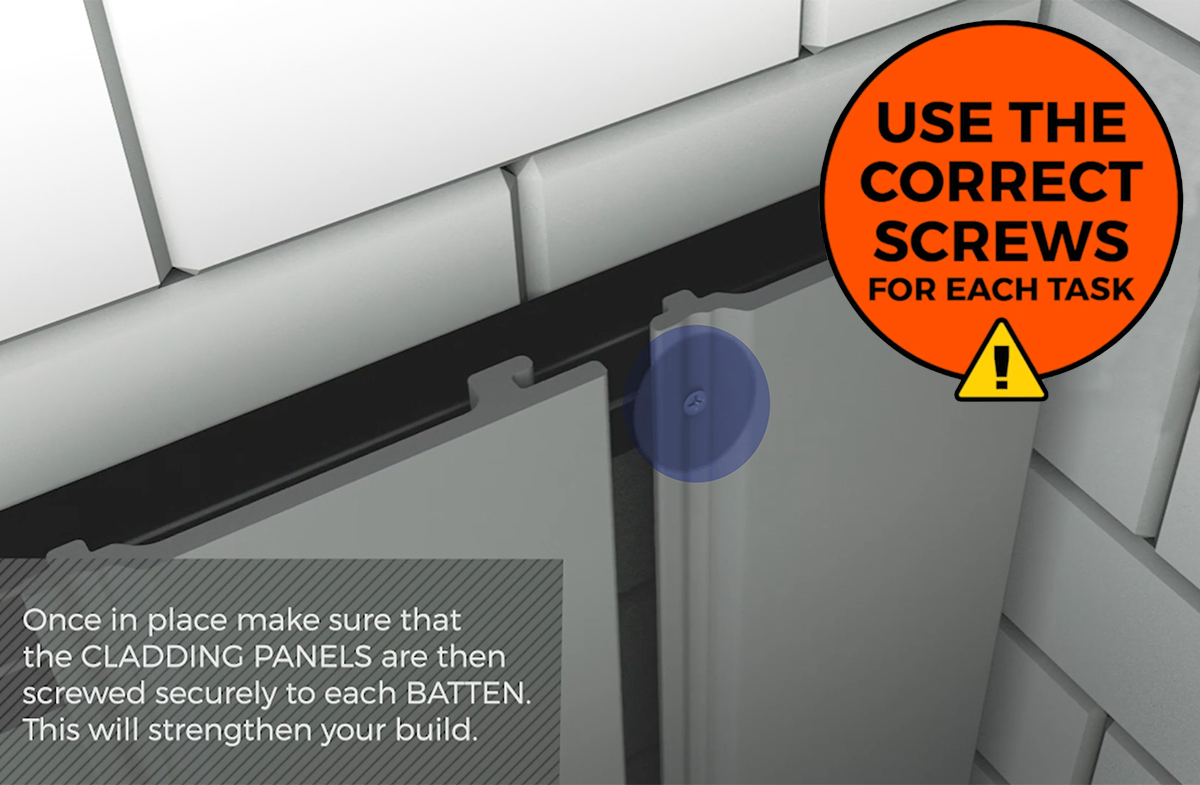

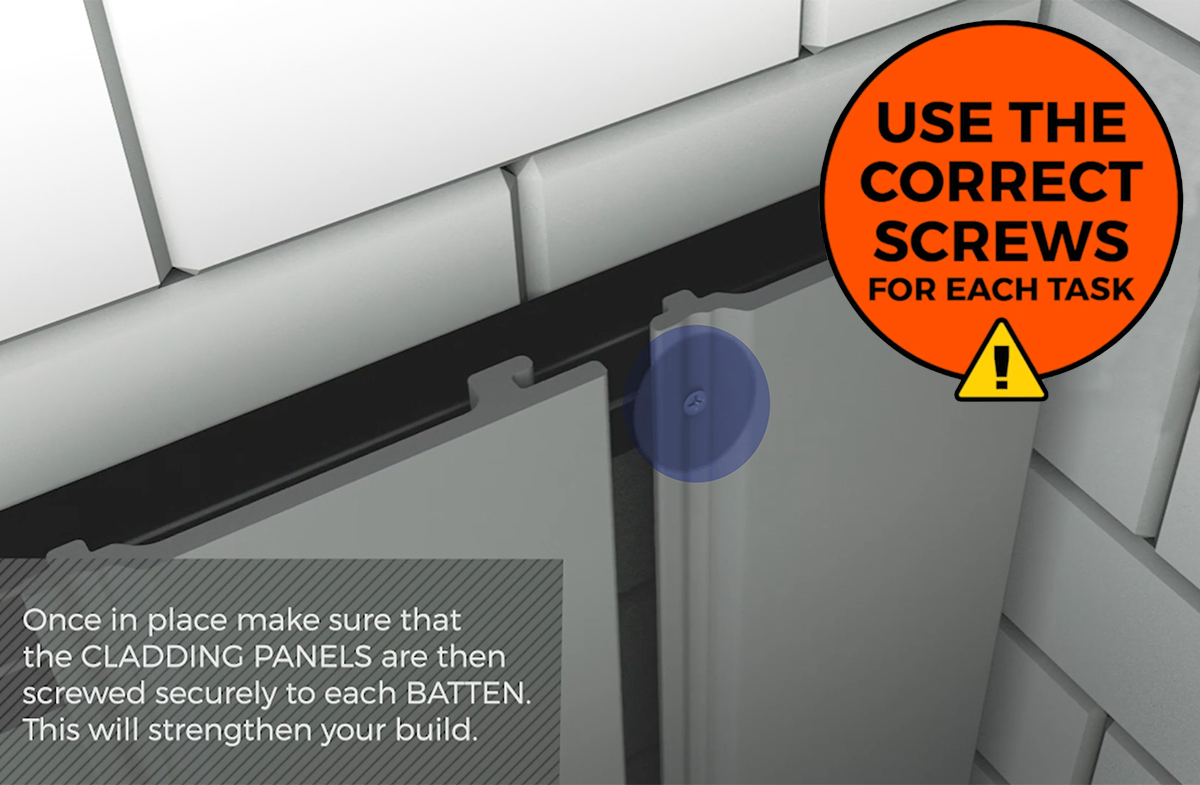

Place the first wall cladding board on to the starter strips. Mark and then pre-drill pilot holes through the fixing groove of the board into the composite batten below. Secure the boards using a screw at least 30mm in length, ensuring that the board is fastened securely on each batten that it touches. Secure these fixings by hand, as it is important not to overtighten the screws and risk splitting the board.

6

Ensure that the section between the battens remains empty allowing air to flow beneath the boards. Slot the second board onto the first and repeat the fixing process ensuring that the second board is fitted securely in place on each batten.

SHARE YOUR PROJECT

We love seeing how our customers have used Cladco ProClad Composite Wall Cladding Boards to transform their buildings. Send us your finished project by emailing photos into [email protected], or tag us on Instagram using @CladcoProfiles.

7

It is possible to fit your boards side by side by simply butting the two ends up together. You may need to install more battens if you wish to do this, as each board will need to be supported on a batten where it meets the next board. Continue to fit the cladding boards in this manner until you have completely covered the area you want.

8

Depending on your installation, you may want to finish off the edges using trims to give you a lasting professional look. There are a range of trims available in all colours to complement your cladding boards, which can be secured to your installation by glue.

Finishing Touches

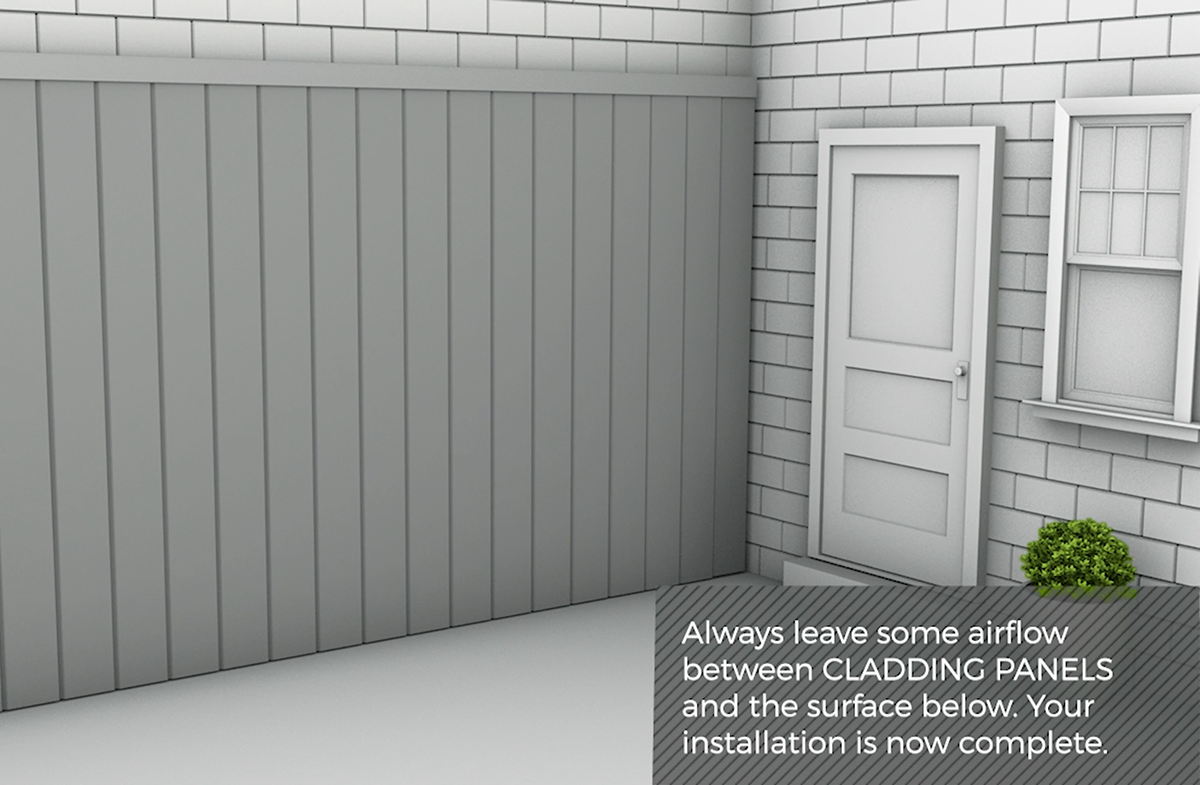

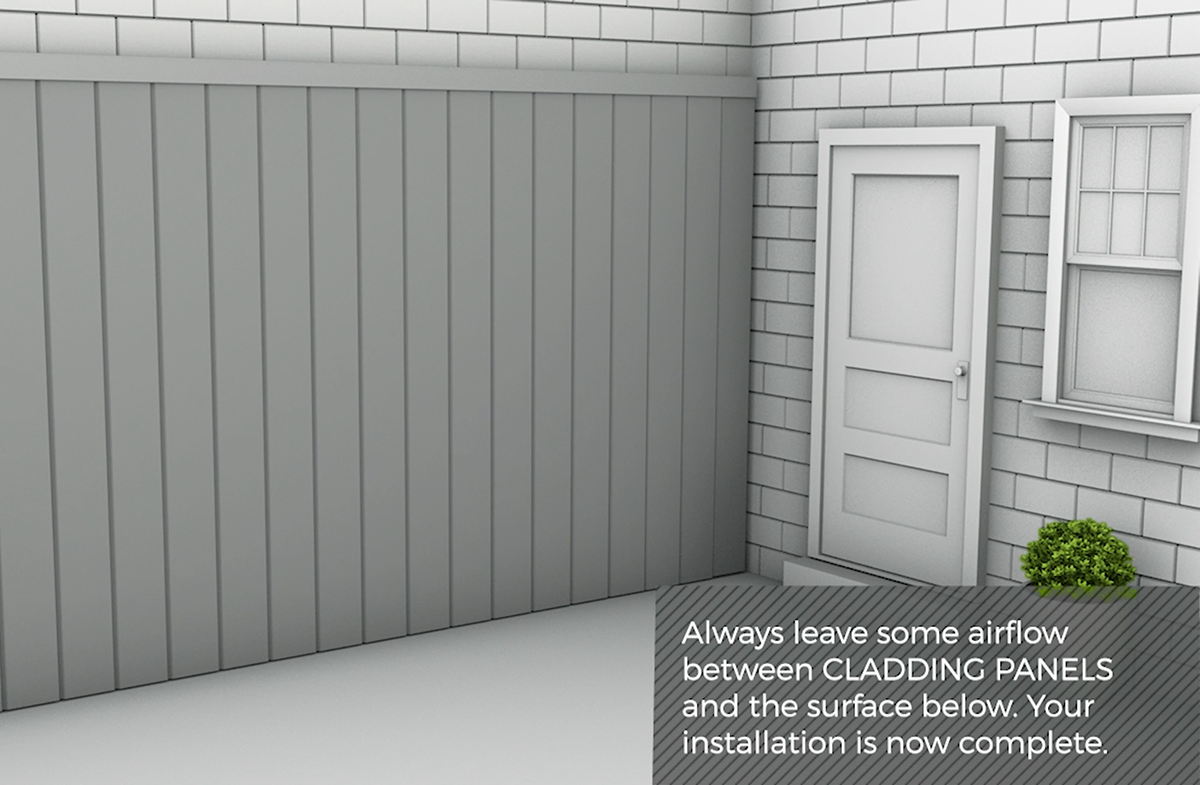

AIRFLOW

Please do not completely seal your installation to allow some air to flow between the cladding boards and the surface below when fitting the trims. Allow for a 10mm air gap between the cladding boards and the base of the installation.

Whether you have installed your ProClad boards vertically or horizontally, you can use matching your ProClad boards to complete the look of your project for a professional touch. ProDeck corner trims can be worked into your installation easily using normal woodworking tools and Cladco high strength adhesive.

Measure the area where the corner trim will be installed—for example, the height and width around a door or window.

Corner trims can be cut to length and worked in the same way as timber. If fitting two trims side by side, you can either mitre them for a clean angled finish or cut them to fit as required.

Once the corner trim is cut to size, apply Cladco adhesive along one or both inner edges to secure it to the cladding.

To allow for expansion, you may choose to apply adhesive only along the top edge. After fixing the first piece, cut and fit the second trim as needed to complete the desired finished look.

Aftercare and Maintenance

MAINTAINING YOUR PROCLAD CLADDING

Cladco ProClad has a 15-year warranty and is stain and fade resistant. In some cases, pressure washing may be required for persistent dirt. When using a pressure washer, it is recommended that a distance of at least 30cm is left between the cladding and the nozzle, to avoid any damage.

For standard everyday debris such as plants, leaves, berries, and animal droppings, simply brush away. Soapy water can also be used to ease this process.

FIRE AND HEAT SOURCES

Take care when using fire pits or BBQs near ProClad Composite Wall Cladding, as embers or direct heat may damage the surface. Cladco cannot be held responsible for any fire-related damage or contact with flames. Using a heat source near the cladding is entirely at the customer’s own risk.

MOULD AND MILDEW

Mould and mildew are common in outdoor environments. The climate will affect how mould grows, dependent on temperature and moisture levels. To minimise mould growth on your cladding, ensure it is cleaned often. If mould is present, use soapy, hot water to remove it. In cases of more stubborn dirt or grime, pressure washing may be necessary to restore the cladding’s appearance.

DISCOLOURATION

Discolouration can be caused by chemicals found in everyday household products, such as suntan lotion, or insect repellent. Take care when using these products near your ProClad boards.

During the first 6-12 months after installation, the colouring of the cladding will stabilise.

FAQS

Can ProClad be installed indoors?

Yes, Cladco ProClad Composite Wall Cladding is a versatile cladding material, designed to transform the exterior of your home. However, the boards can easily be installed indoors, if desired.

Can I use a pressure washer?

A pressure washer can be used to clean your ProClad cladding boards. We recommend using a pressure washer with a psi of no greater than 2,000.

A fan tip should be used with a 40 to 60° spread, keeping the head 250-300mm away from the surface. Always test in an inconspicuous area first. Direct, prolonged contact could damage the surface of the boards and should be avoided.

Do I need planning permission to install my wall cladding?

In most cases, adding cladding to your home does not require planning permission, providing that the materials are of a similar appearance to the rest of your home. In some cases, you may need to apply for planning permission if your home is a listed building in an area of exceptional beauty or a national park. Please note that we are not licensed planning or building surveyors. We recommend speaking to a licenced professional.

Do I need to paint my ProClad Composite Wall Cladding Boards?

Cladco ProClad Composite Wall Cladding Boards are available in a variety of seven colours. The lowmaintenance composite material with a capped polymer shell does not need to be sanded, treated or painted. Simply select your chosen colour, install and enjoy.

What is ProClad Cladding made of?

Cladco ProClad Composite Wall Cladding products are manufactured from a mix of recycled hardwood fibres and recycled plastic that makes up the composite core. This is then capped with a polymer protective shell for increased strength.

What colours are available?

ProClad cladding is available in seven colours to match your chosen design or to blend into the environment. ProDeck corner trims are also available in the same seven colours.

Do ProClad Cladding Boards fade?

These cladding boards may undergo a stabilisation process, during which a slight colour change may occur as they reach their final colour. This process generally takes place within the first six months following installation.

How much do ProClad Cladding products weigh?

Cladco ProClad Composite Wall Cladding Boards are available in 3.6m lengths. Each board weighs approximately 6.15kg.

Is ProClad cladding maintenance-free?

ProClad cladding needs less upkeep and is less maintenance than traditional timber or even composite cladding options. However, the cladding may accumulate dirt over time as with most building exteriors. This can be easily removed with a brush and water if needed. For more stubborn debris, soapy water can be used to facilitate the cleaning of the surface.

Why are watermarks appearing on my composite cladding?

Watermarks may occur as a result of the weathering process associated with composite materials. As the tannins from the timber content of the boards come to the surface, these marks can become visible. This condition is temporary, and the marks will naturally fade as the cladding stabilises.

Do ProClad boards fade?

Composite materials are prone to fading over time. Although the core of the ProClad boards ismade from this material, the capped shell should minimise this. If this does occur, the colour should stabilise within the first 6-12 months after installation.

Are ProClad boards susceptible to scratching?

The polymer-capped protective shell makes the ProClad boards highly resistant to scratching, as well as stains, mould and varying weather conditions.

Do some colours need more maintenance than others?

Some of our lighter cladding colours, such as Sandstone, can show dirt more easily, so you will likely need to clean them more often than our darker colours.

Why is airflow behind the boards necessary?

Cladco ProClad Composite Wall Cladding functions as a rain screen cladding option, which allows adequate airflow to enable proper ventilation of any rainwater that may penetrate the cladding. Without sufficient airflow, standing water will not evaporate, which can lead to mould spots on your cladding.

Why is spacing at the ends of the Boards required?

Ventilation behind your cladding boards is crucial for the evaporation of excess water. Allowing space at the ends of the boards, around the perimeter of your installation, provides an exit for air and improves moisture control.

Can This Be Used on Domestic Properties?

Cladco ProClad Composite Wall Cladding is an appropriate choice for exterior applications on domestic properties. However, it is the responsibility of the customer to ensure that the product complies with relevant building standards and regulations. Cladco shall not assume any liability should the products fail to meet specific building, fire, structural, or other legal requirements pertinent to your intended use or installation.

Why is mould appearing on my cladding?

Mould or mildew may develop due to airborne spores. Ensure proper airflow behind the cladding and maintain adequate spacing during installation. Regular checks and cleaning will keep your cladding in excellent condition.