Fibre Cement Lap Cladding Installation Guide

Installation Guide, Aftercare and FAQS

Important Advice Prior to Installation

Do not install fibre cement lap wall cladding if the boards, building or the surrounding areas are wet.

Do not dry sweep dust or debris off the boards, as it may cause the particles to enter the air and could be inhaled – wipe away with a damp cloth.

Nail guns can be used for fixing the boards.

Do not cut the fibre cement lap wall cladding boards indoors.

Always follow the manufacturer’s safety recommendations when using saws or other machinery.

Always carry fibre cement lap boards upright with the help of another physically abled person.

Storage and Warranty

STORAGE AND HANDLING

Cladco fibre cement lap wall cladding boards should always be stored in a cool, dry, shaded spot, on a flat level surface with the entire board supported. Ensure boards are protected from the weather, dust, water and debris. It is recommend to store the boards indoors.

Installing Cladco fibre cement lap boards while wet increases the likelihood of efflorescence and butt ends shrinking. We recommend installing boards in dry conditions only. Cladco fibre cement lap wall cladding boards should always be moved and carried by two physically abled people, edge to edge, to prevent the boards from bending, cracking or splitting. Take care when handling and moving the fibre cement lap boards, and avoid bending or arching movements, as this can cause them to break.

10 YEAR WARRANTY

Cladco fibre cement lap wall cladding boards are supplied with a 10-year warranty subject to terms and conditions. Cladco fibre cement lap wall cladding boards should be installed as per this installation guide. Failure to do so may invalidate the warranty. For further information, visit our terms and condition page.

Installing Cladco fibre cement lap boards while wet increases the likelihood of efflorescence and butt ends shrinking. We recommend installing boards in dry conditions only. Cladco fibre cement lap wall cladding boards should always be moved and carried by two physically abled people, edge to edge, to prevent the boards from bending, cracking or splitting. Take care when handling and moving the fibre cement lap boards, and avoid bending or arching movements, as this can cause them to break.

Tools and Equipment

PROTECTIVE EQUIPMENT

Cladco fibre cement lap wall cladding boards should always be stored in a cool, dry, shaded spot, on a flat level surface with the entire board supported. Ensure boards are protected from the weather, dust, water and debris. It is recommend to store the boards indoors.

Installing Cladco fibre cement lap boards while wet increases the likelihood of efflorescence and butt ends shrinking. We recommend installing boards in dry conditions only. Cladco fibre cement lap wall cladding boards should always be moved and carried by two physically abled people, edge to edge, to prevent the boards from bending, cracking or splitting. Take care when handling and moving the fibre cement lap boards, and avoid bending or arching movements, as this can cause them to break.

TOOL SET

Cladco fibre cement lap wall cladding boards should always be stored in a cool, dry, shaded spot, on a flat level surface with the entire board supported. Ensure boards are protected from the weather, dust, water and debris. It is recommend to store the boards indoors.

Installing Cladco fibre cement lap boards while wet increases the likelihood of efflorescence and butt ends shrinking. We recommend installing boards in dry conditions only. Cladco fibre cement lap wall cladding boards should always be moved and carried by two physically abled people, edge to edge, to prevent the boards from bending, cracking or splitting. Take care when handling and moving the fibre cement lap boards, and avoid bending or arching movements, as this can cause them to break.

CUTTING TOOLS

Cladco fibre cement lap wall cladding boards should always be stored in a cool, dry, shaded spot, on a flat level surface with the entire board supported. Ensure boards are protected from the weather, dust, water and debris. It is recommend to store the boards indoors.

Installing Cladco fibre cement lap boards while wet increases the likelihood of efflorescence and butt ends shrinking. We recommend installing boards in dry conditions only. Cladco fibre cement lap wall cladding boards should always be moved and carried by two physically abled people, edge to edge, to prevent the boards from bending, cracking or splitting. Take care when handling and moving the fibre cement lap boards, and avoid bending or arching movements, as this can cause them to break.

STAPLE GUN

Cladco fibre cement lap wall cladding boards should always be stored in a cool, dry, shaded spot, on a flat level surface with the entire board supported. Ensure boards are protected from the weather, dust, water and debris. It is recommend to store the boards indoors.

Installing Cladco fibre cement lap boards while wet increases the likelihood of efflorescence and butt ends shrinking. We recommend installing boards in dry conditions only. Cladco fibre cement lap wall cladding boards should always be moved and carried by two physically abled people, edge to edge, to prevent the boards from bending, cracking or splitting. Take care when handling and moving the fibre cement lap boards, and avoid bending or arching movements, as this can cause them to break.

HEALTH AND SAFETY

Cladco fibre cement lap wall cladding boards should always be stored in a cool, dry, shaded spot, on a flat level surface with the entire board supported. Ensure boards are protected from the weather, dust, water and debris. It is recommend to store the boards indoors.

Installing Cladco fibre cement lap boards while wet increases the likelihood of efflorescence and butt ends shrinking. We recommend installing boards in dry conditions only. Cladco fibre cement lap wall cladding boards should always be moved and carried by two physically abled people, edge to edge, to prevent the boards from bending, cracking or splitting. Take care when handling and moving the fibre cement lap boards, and avoid bending or arching movements, as this can cause them to break.

Preparing the Wall

1

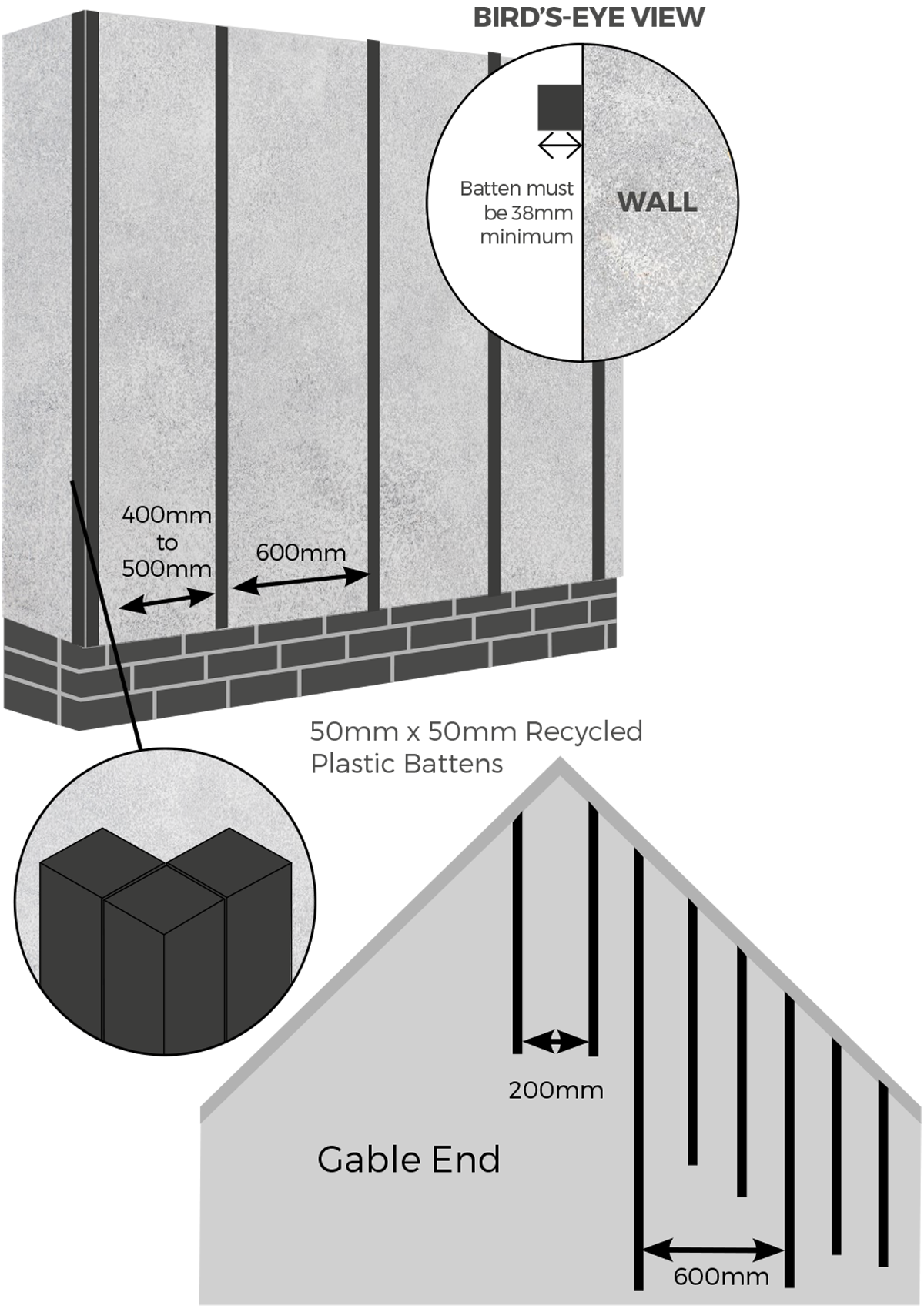

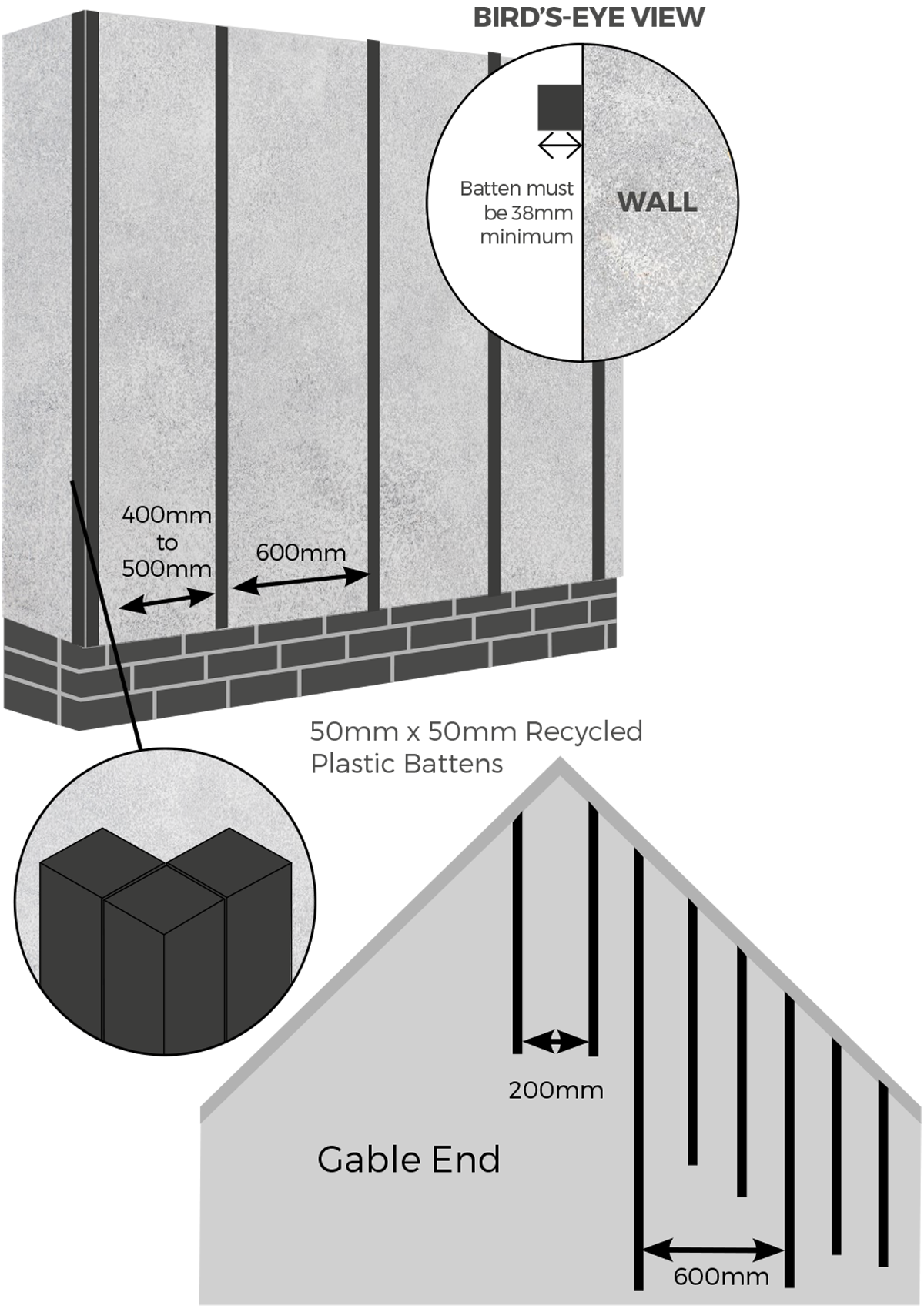

Install 50mm x 50mm recycled plastic battens flush to the wall, creating a minimum 38mm ventilation gap between the wall and the fibre cement lap cladding boards.

Battens must be no more than 600mm apart, reducing to 400mm or 500mm at boundary areas, and a clear space of 38mm should be left at the base of the battens.

If your home has a gable end, battens must be spaced up to 600mm apart with additional, shorter supporting battens installed every 200mm between, going up and down the apex (the triangular shape of your gable end). This ensures the boards are fully supported across the entire build.

Ensure all battens are vertical and level using either a tape measure or a spirit level before moving on to the trims and details.

Please note: the damp proof course must be installed on any battens around corners, or on any double battens (where two cladding boards are butted together).

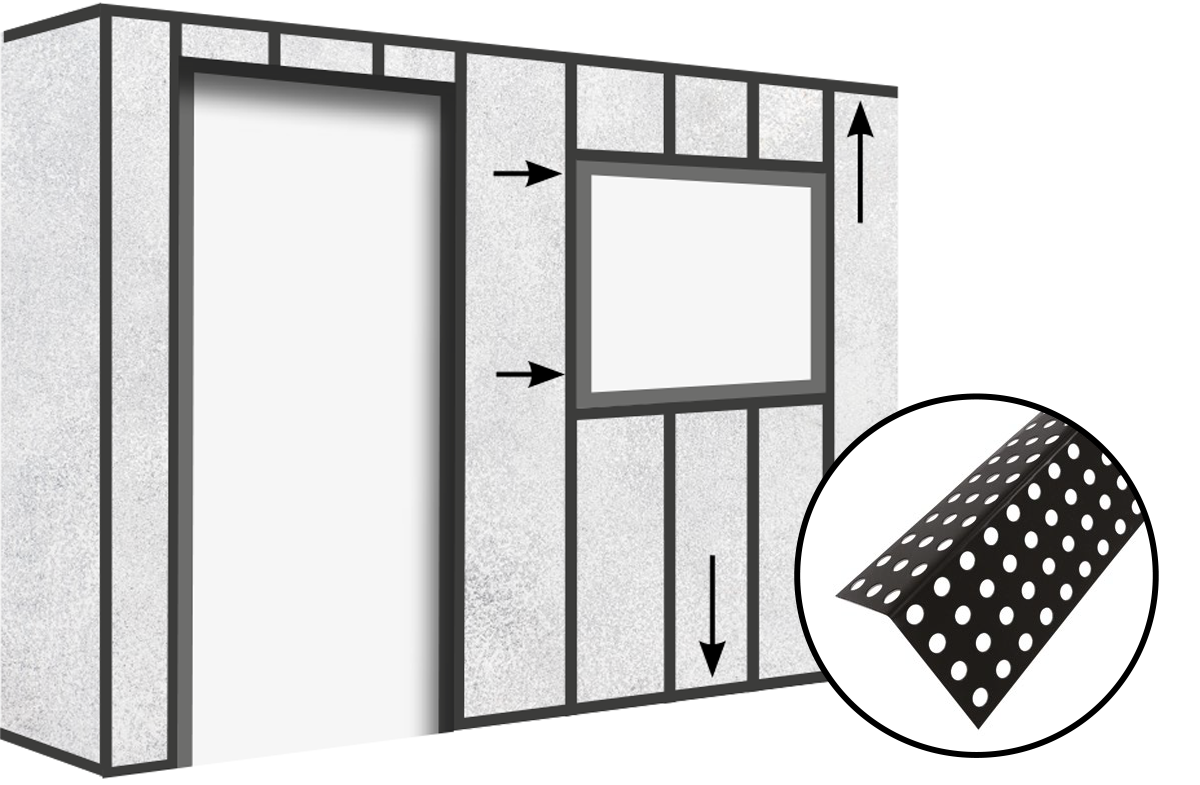

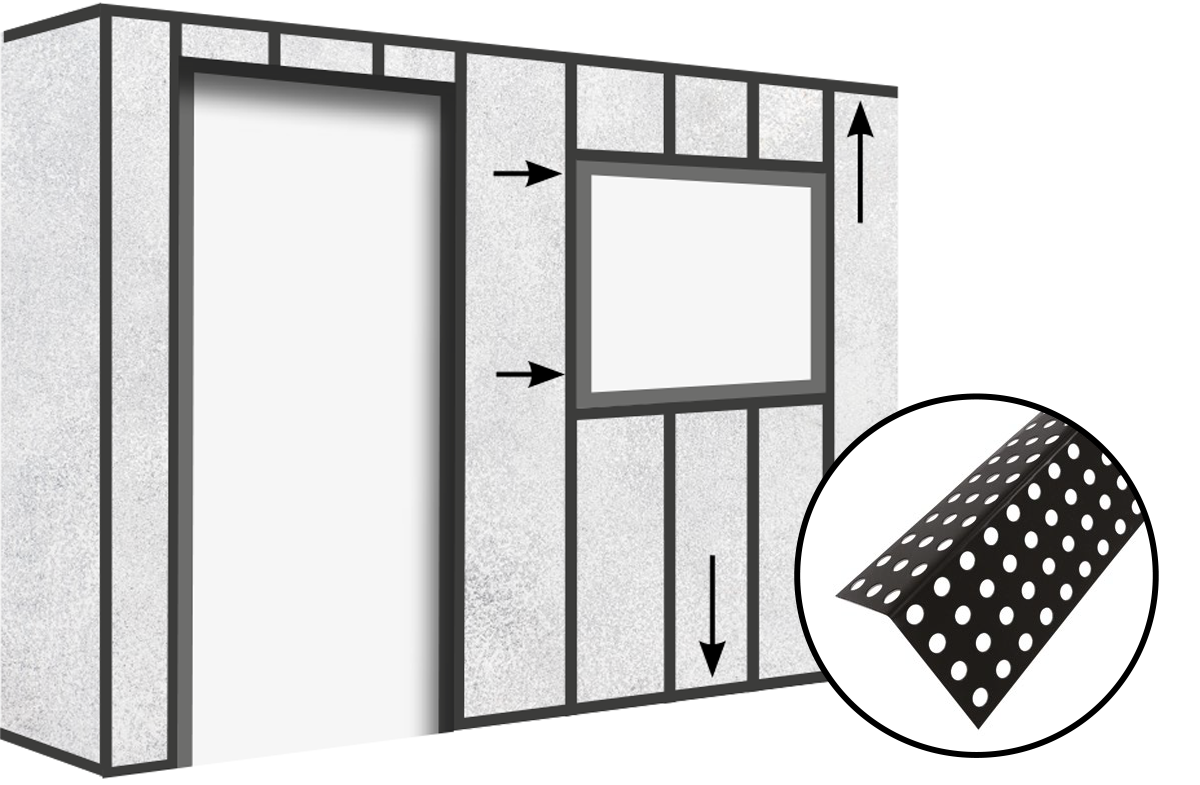

Installing the Boards

2

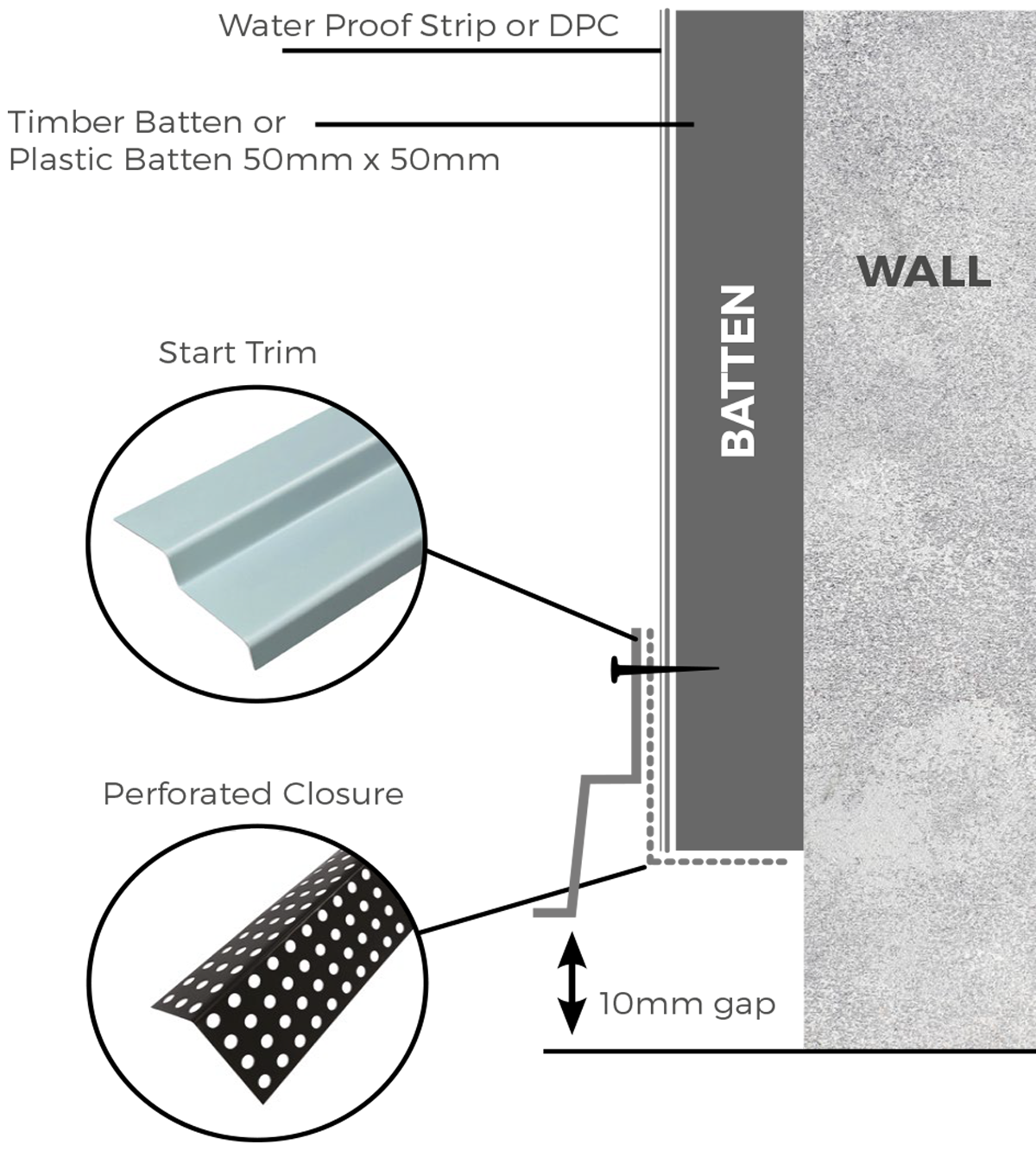

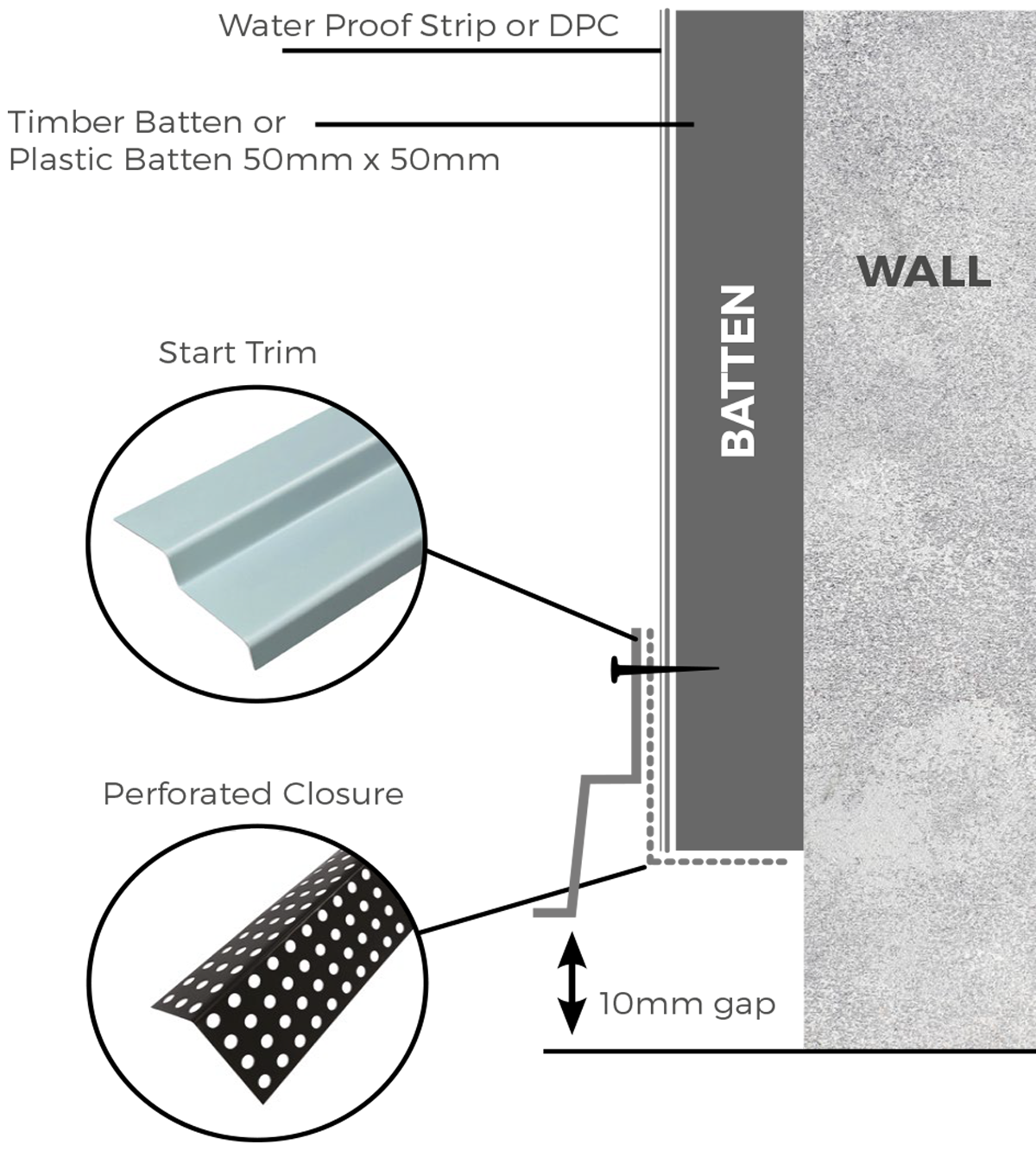

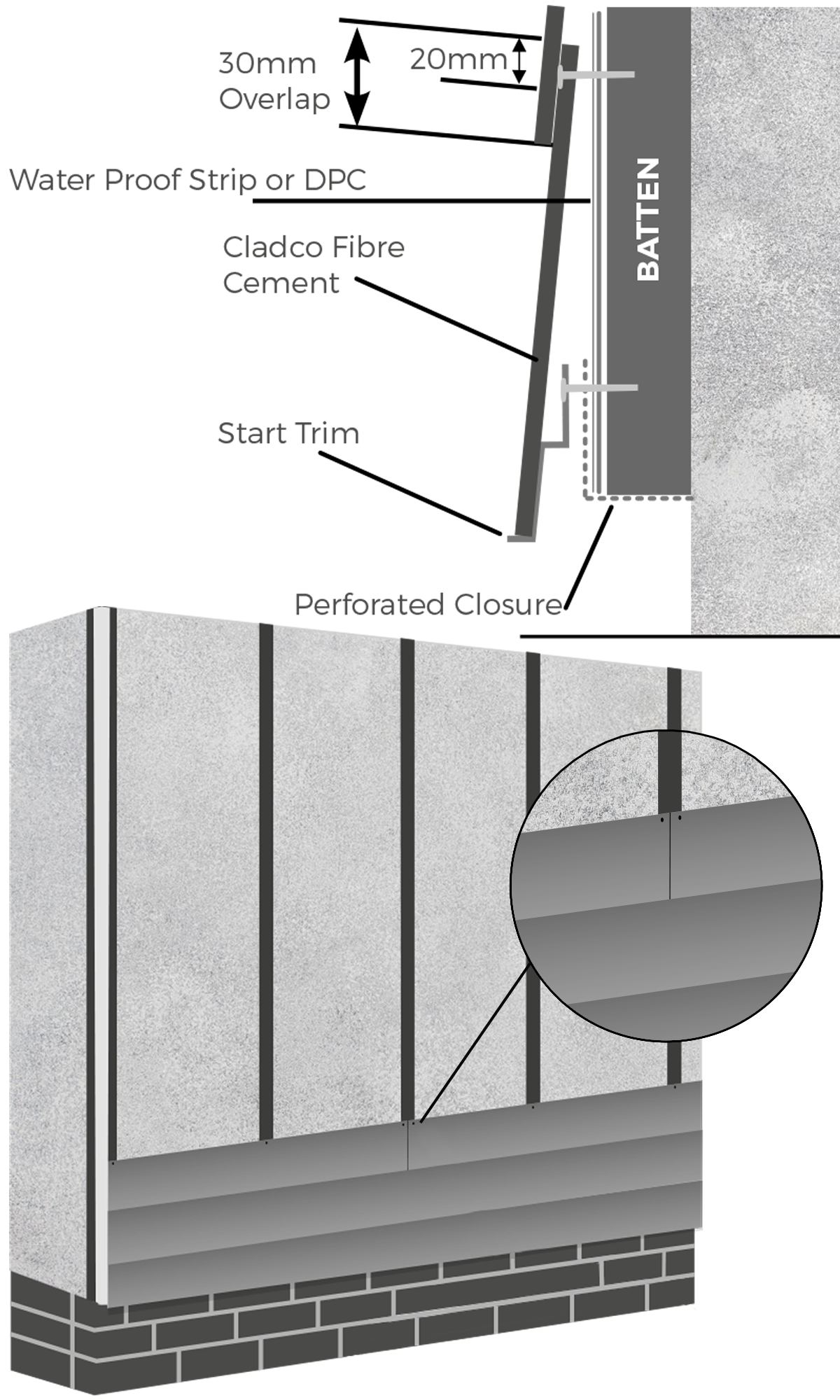

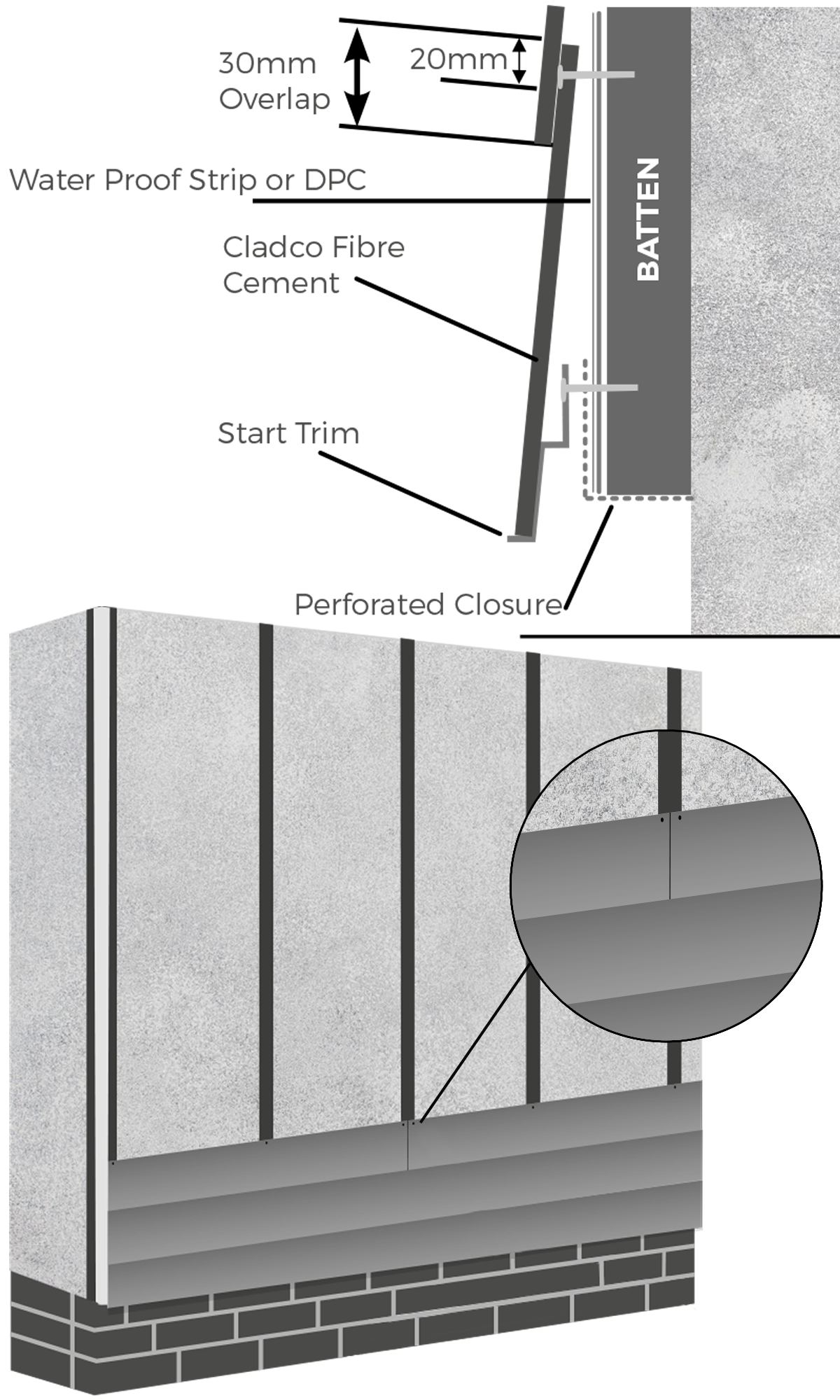

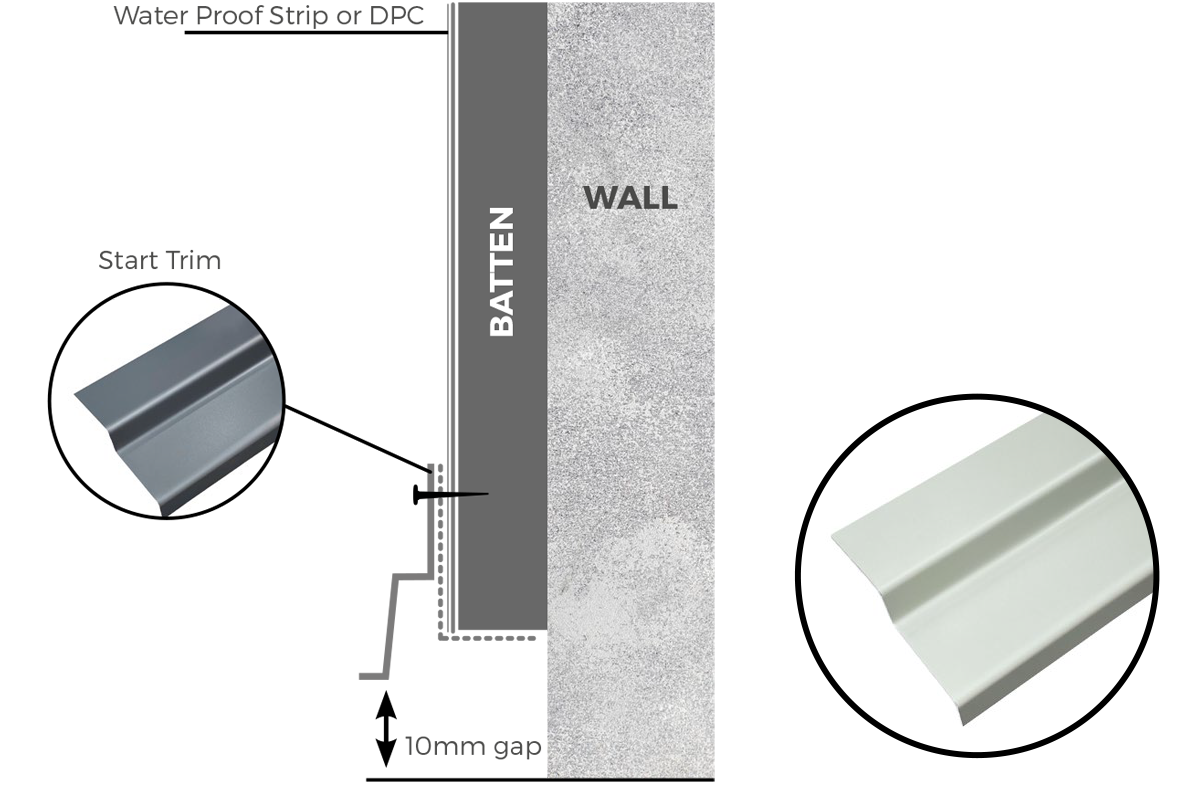

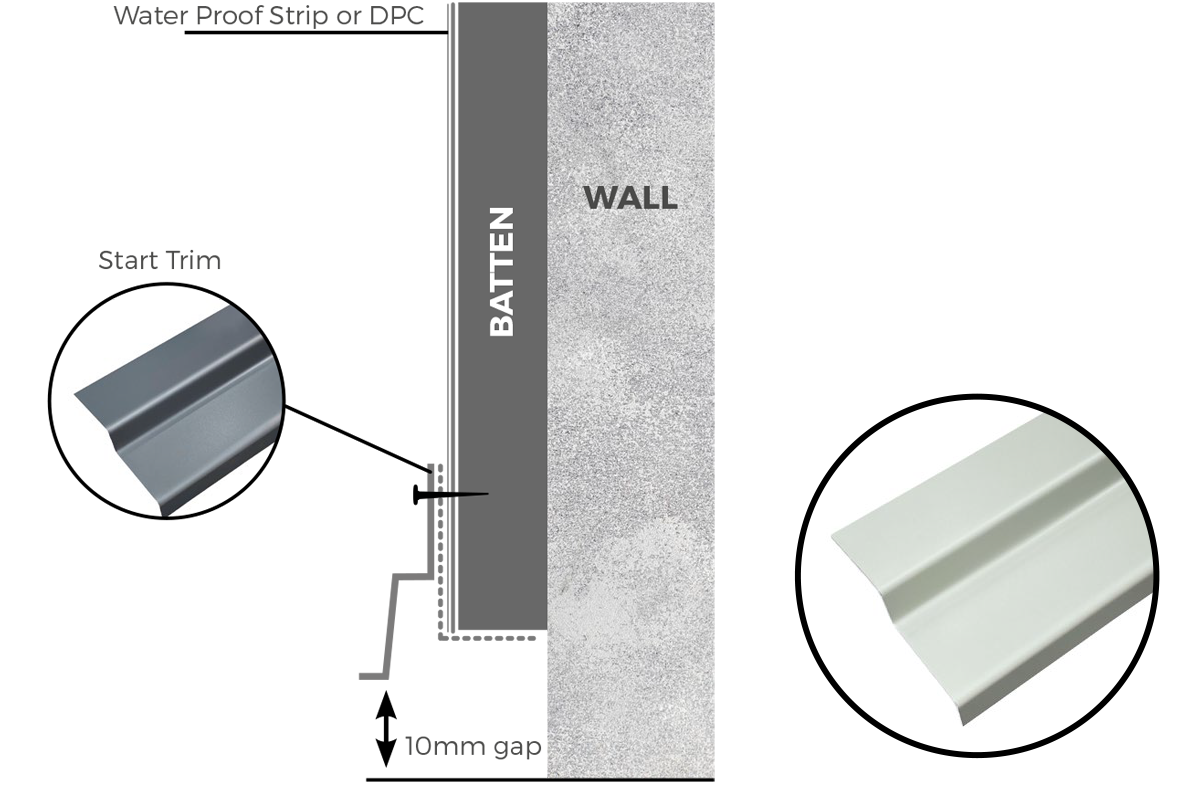

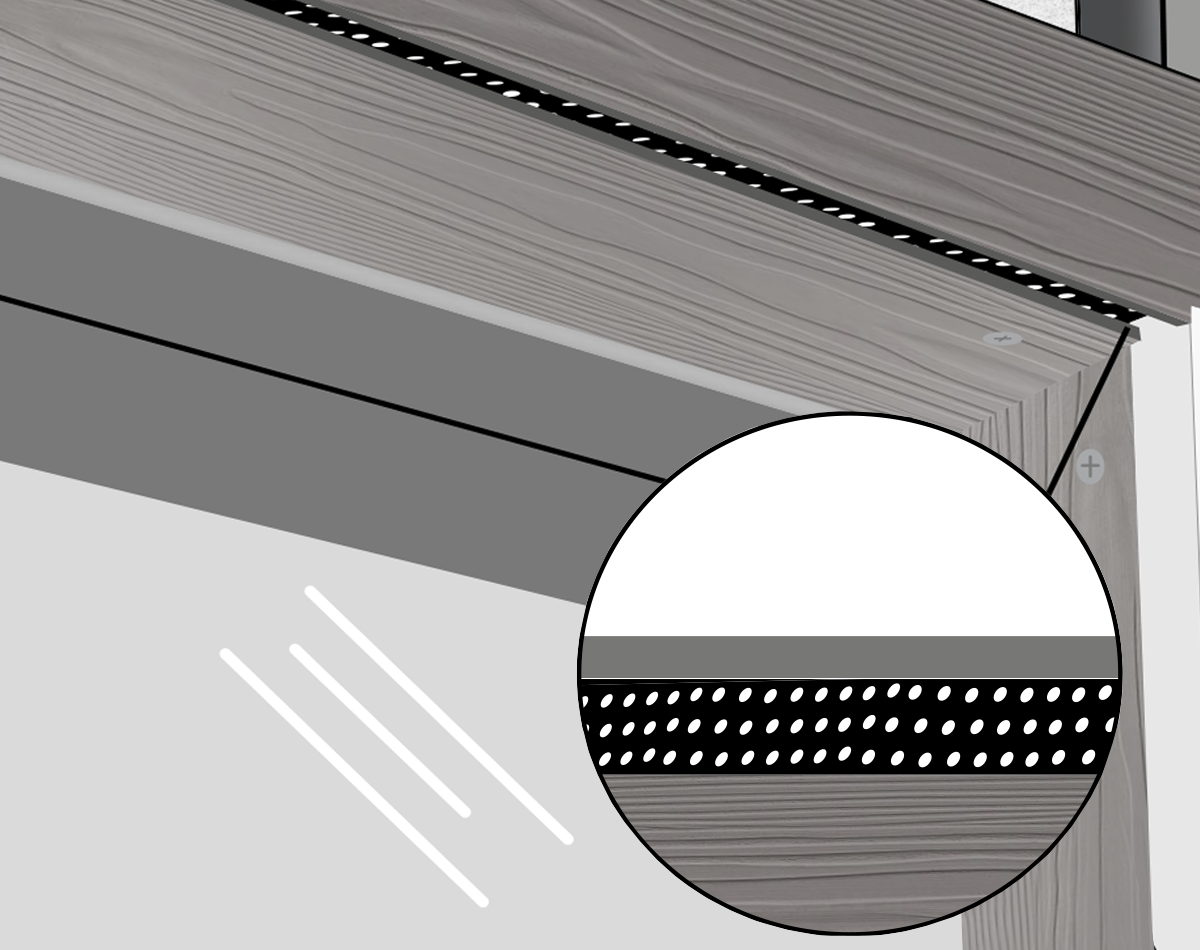

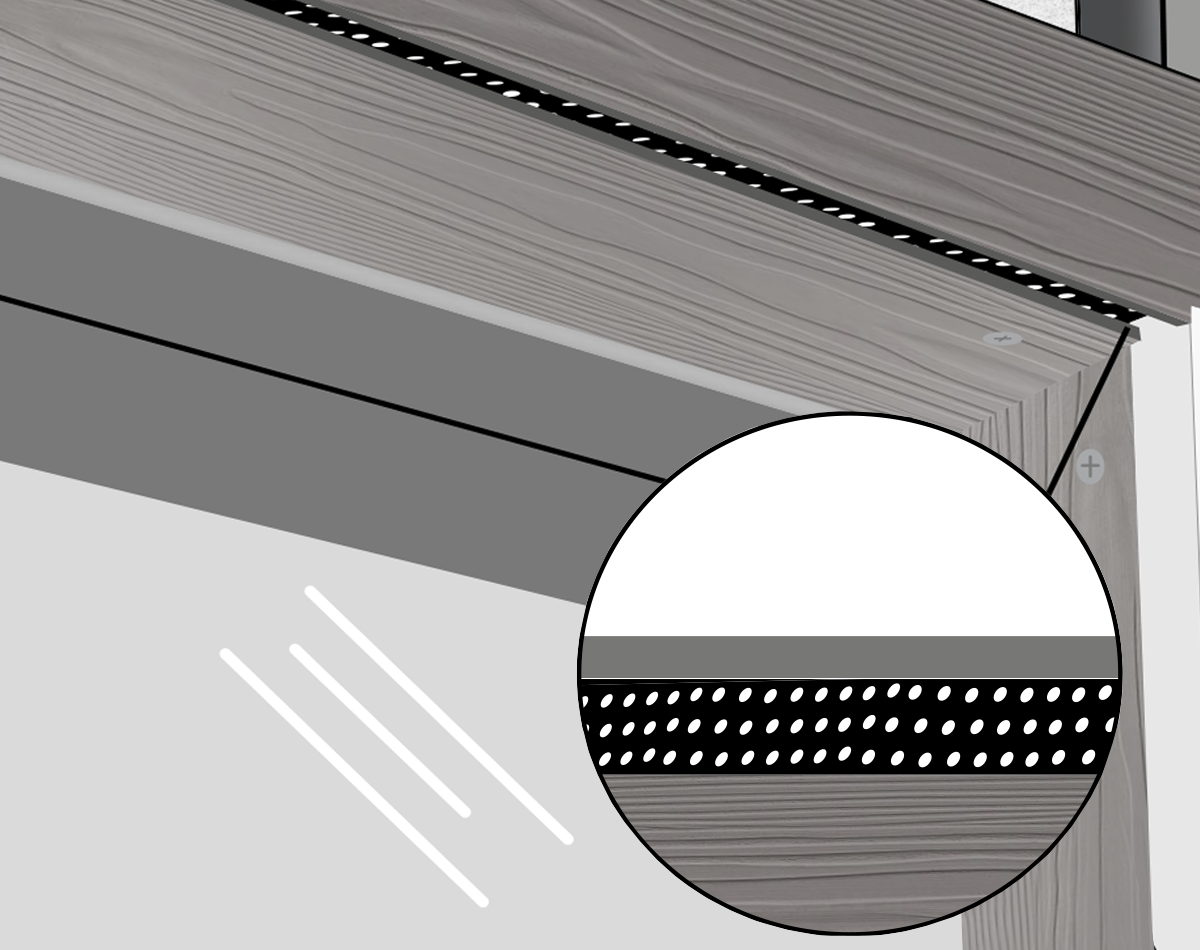

Once the battens are installed a water proof strip or DPC (damp proof course) must be fitted to any batten which will have a corner trim attached to it, or borders any windows or doors. Fix the DPC using a staple gun at regular intervals. Then, at the base of the battens secure the perforated closure using 39mm fibre cement screws.

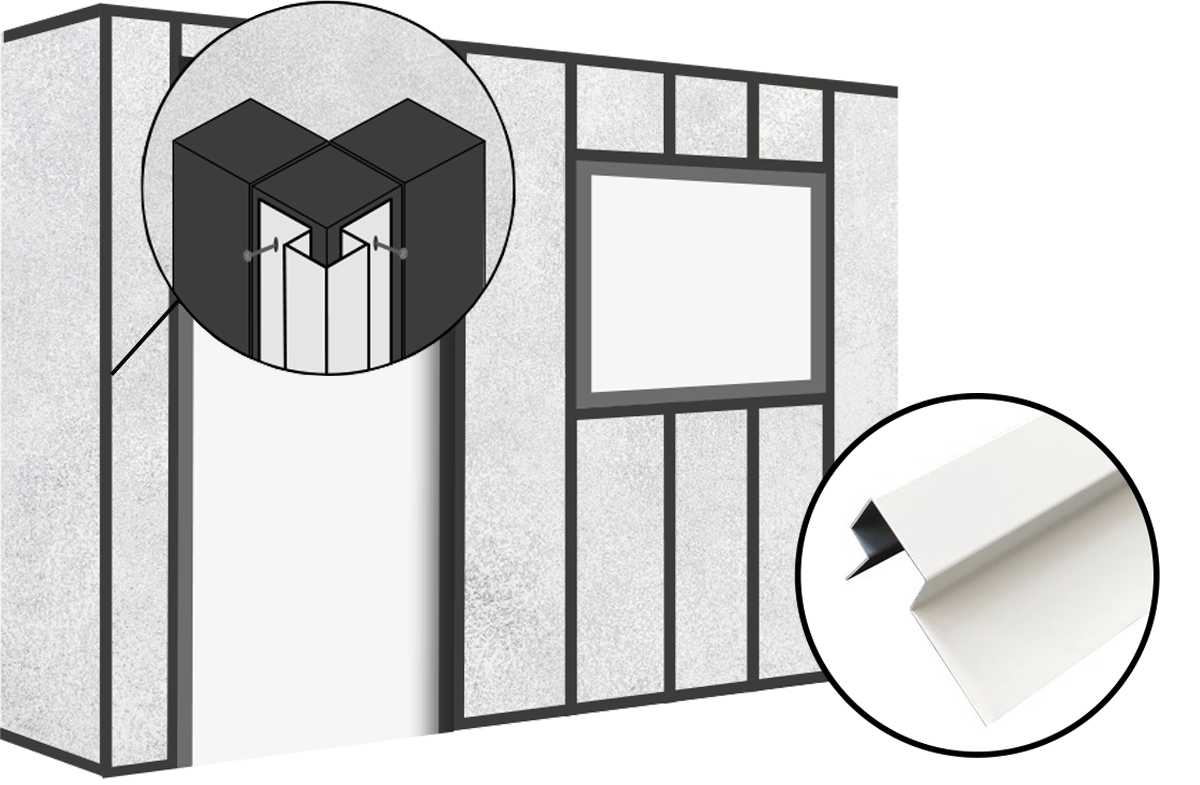

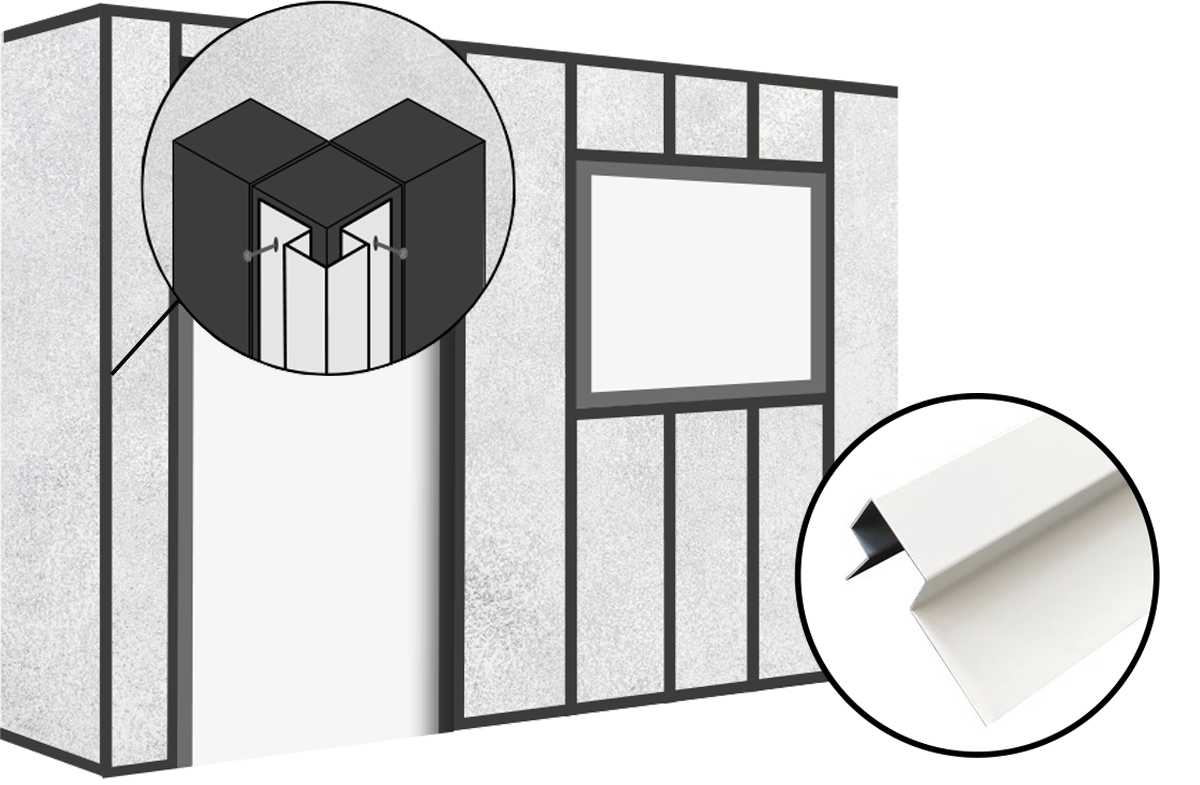

Fix corner trims to the battens, ensuring each trim overlaps the batten on either side by 10mm. Fix the trim to the batten using 39mm fibre cement screws, at regular intervals until the trim is secure.

Screw the start trim to the batten, as per the diagram, only at the top of the trim and through both the batten and perforated closure at the base.

Ensure the lip of the start trim is just below the base of the batten. Make sure there is a 10mm clearance between the base of the trim and the base of the wall.

3

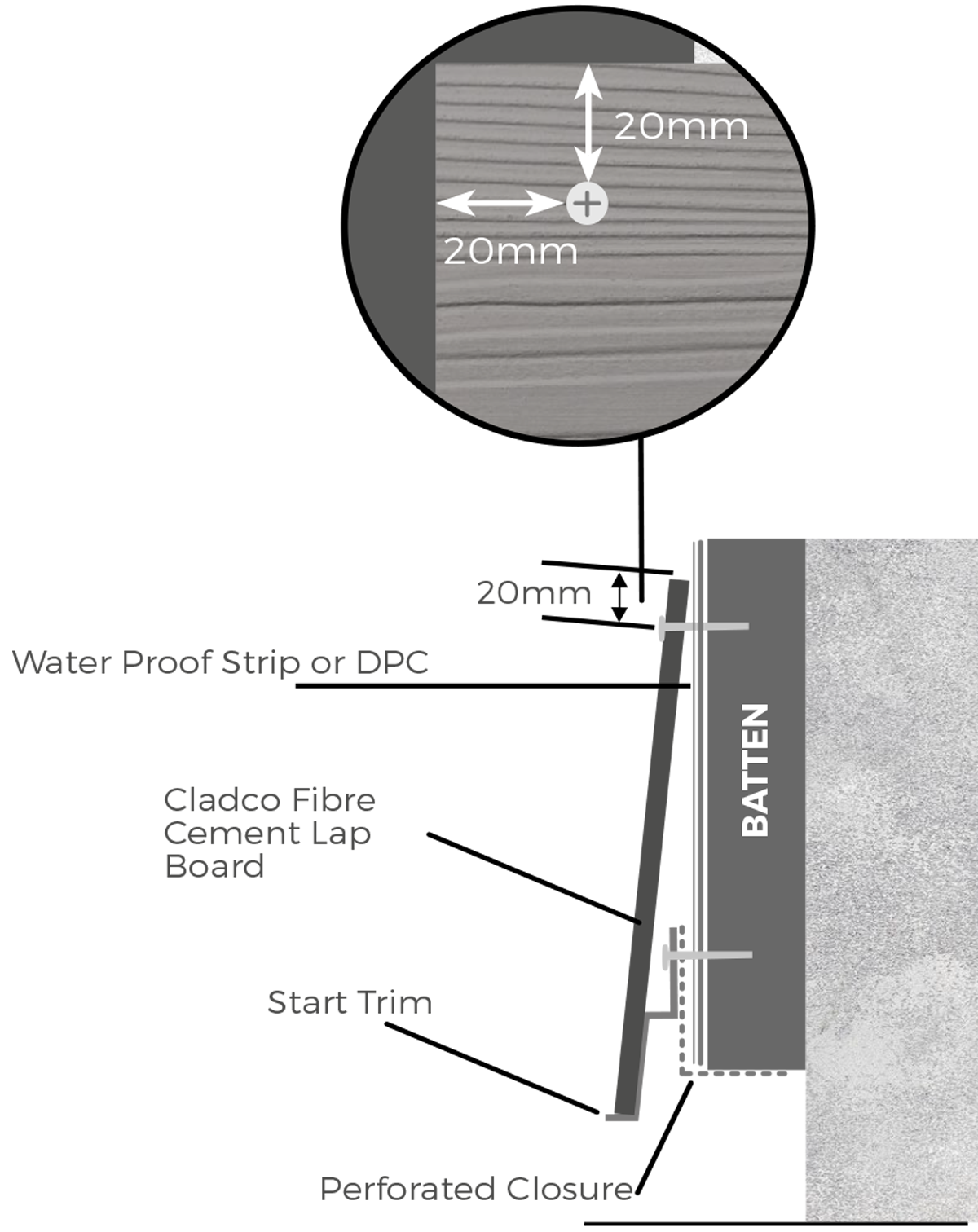

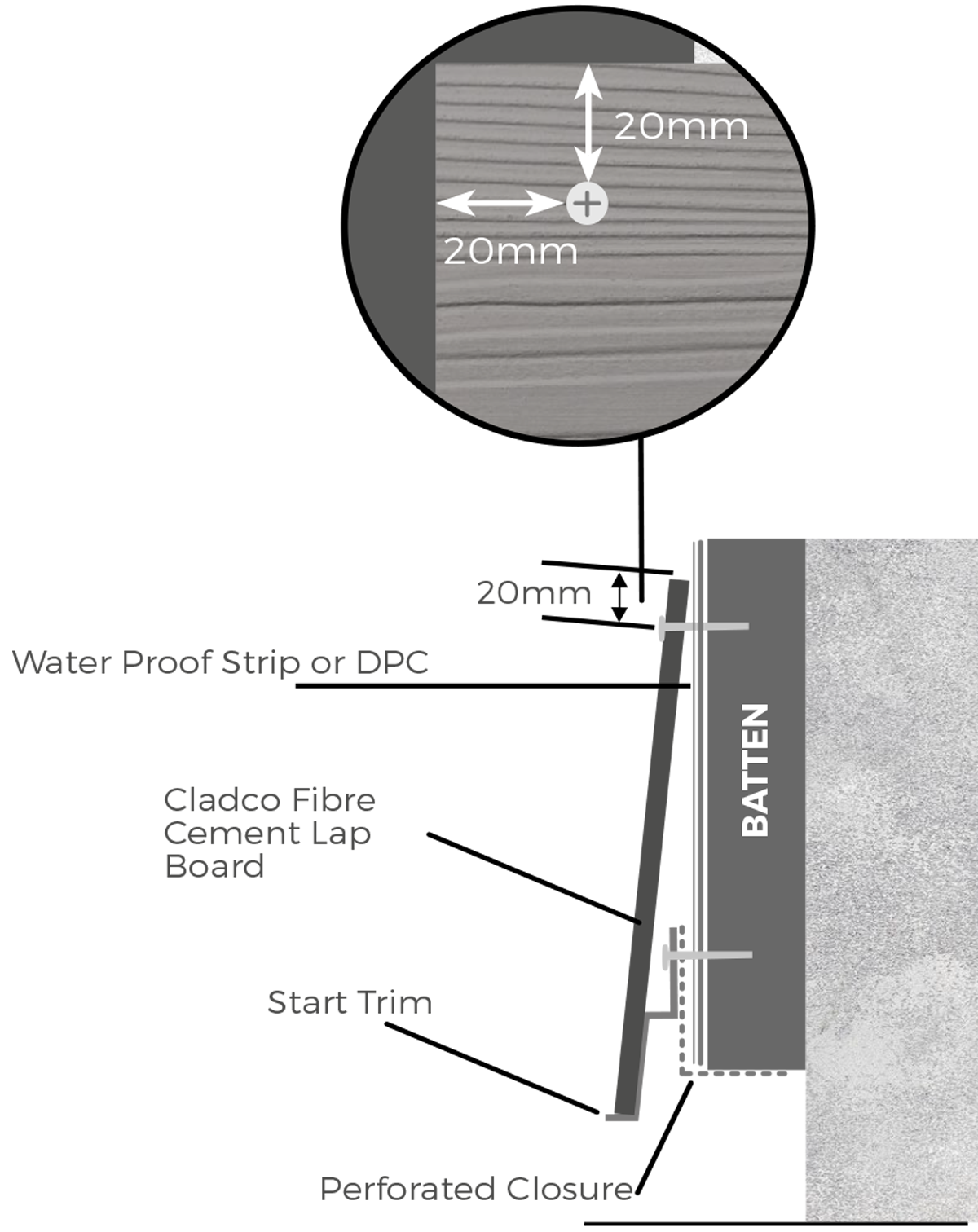

The first board will be fixed to the side of the building using the attached start trim as a support.

Mark 180mm up from the base of the start trim and ensure it is level. This will be where the top of your first board will sit.

Sit the board securely onto the start trim and fix to the battens behind with a 40mm wood screw. Screws should always be inserted at the top of the board into the battens.

There must be a 20mm clearance gap between the edge of the board and each screw.

If the Screw location is within 50mm of the board’s end, pre-drilling is required. We recommend using a 5mm drill bit in conjunction with our M4x40 screws.

Screw fixing to the support structure can be achieved without pre-drilling where fixings are at least 50mm from the end of the board.

4

Place your second fibre cement lap wall cladding board so that the base of the board overlaps the top of the first board by a minimum of 30mm. The dimensions of the overlap must be maintained throughout the installation.

Insert 40mm wood screws through the top of the new cladding board into the batten as before.

Once the board has been secured, measure 180mm from the top of the board to give the next board’s top rate edge height. This is to ensure that the correct gaps are being met throughout the installation. Install the rest of the boards following this method.

Top tip: to ensure coverage of your desired width, the fibre cement lap wall cladding boards may need to be butted together. The boards can be flush next to each other, as the boards have a minimal expansion and contraction. When two boards meet, they must be supported by two adjacent battens behind.

The double battens must both be fitted with a damp proof course before the boards are installed.

5

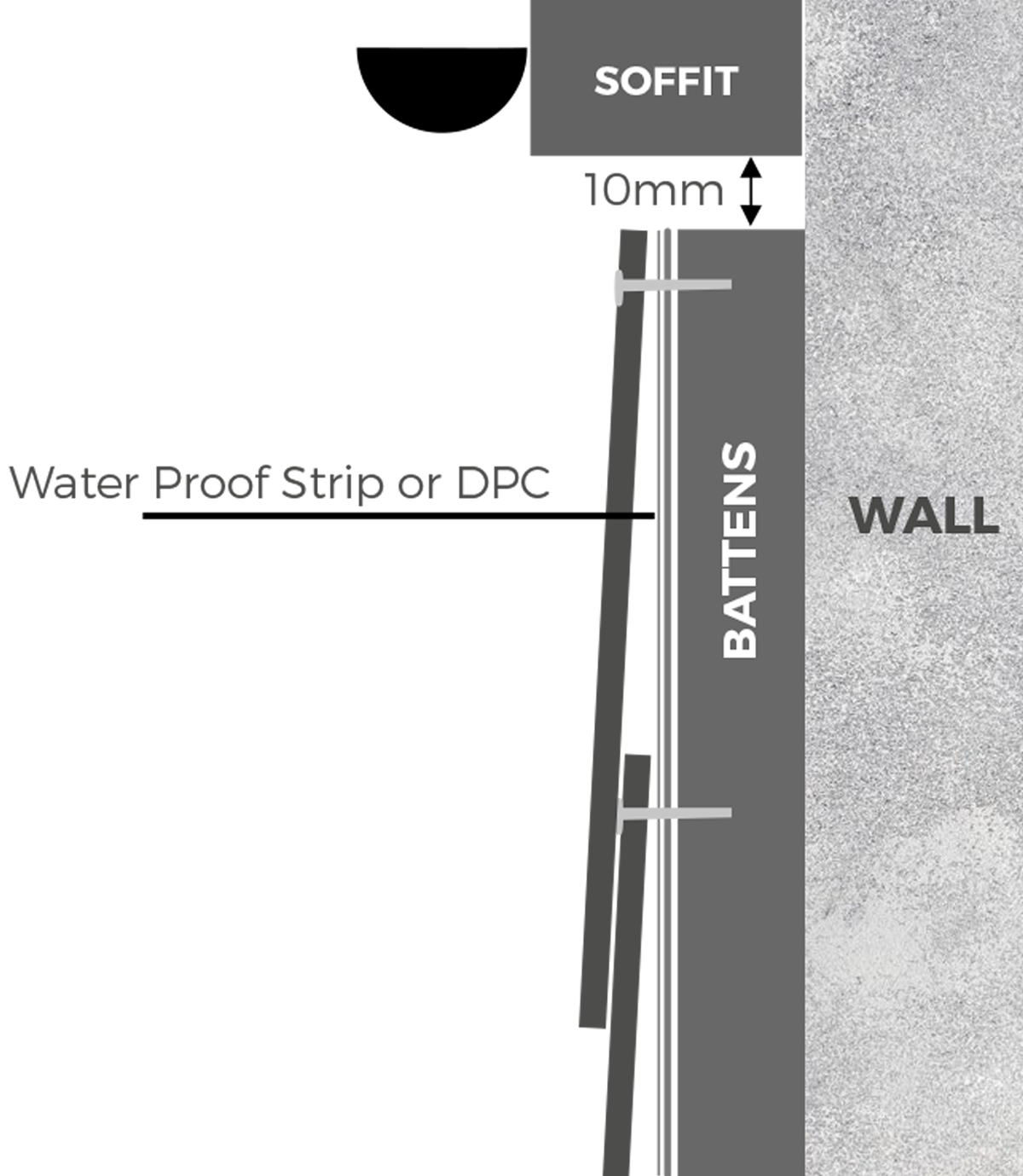

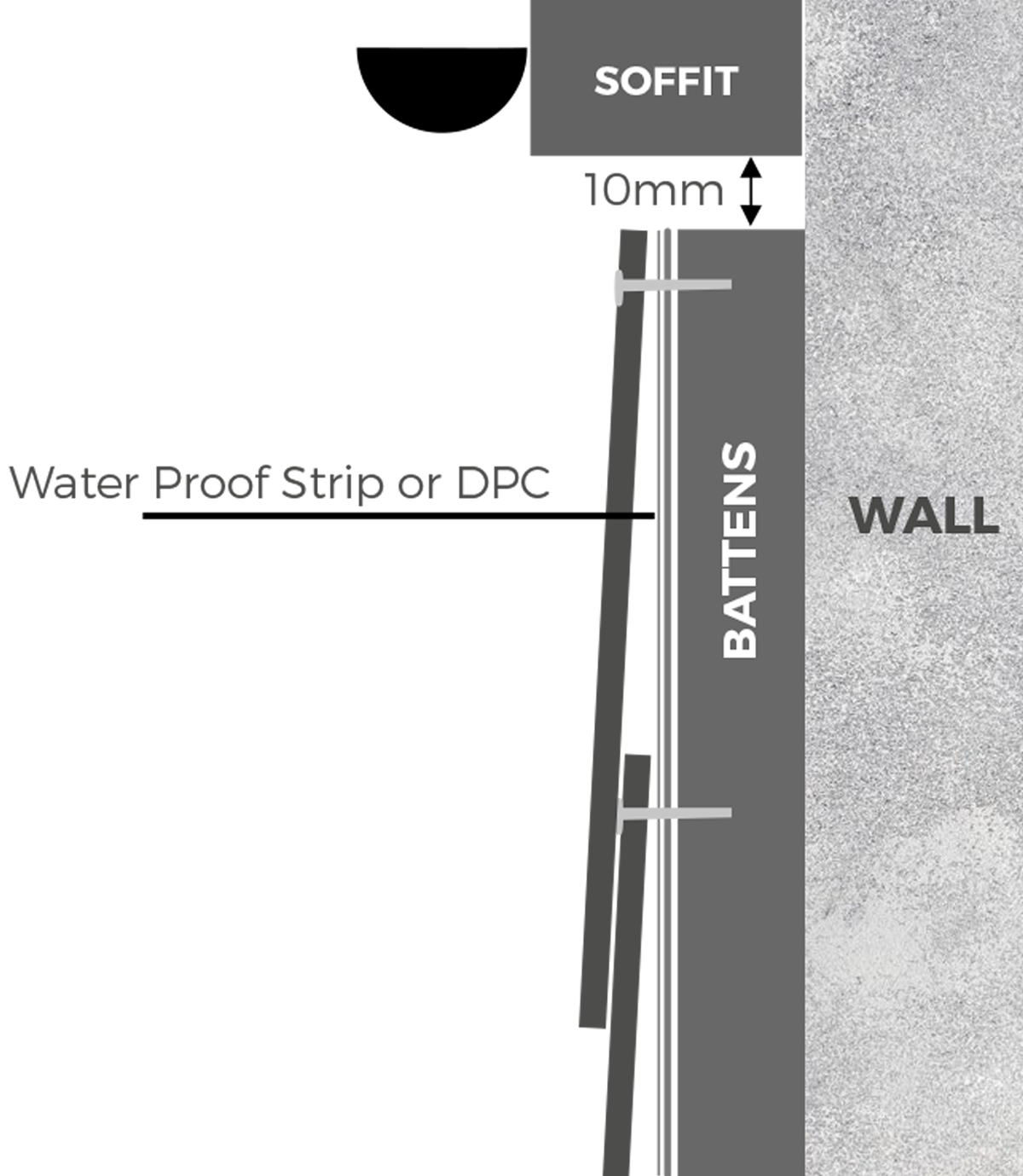

It is unlikely that boards will fit exactly to your wall height, and so it may be necessary to cut the last board to the correct width. To ensure the board is cut correctly, measure the distance from the top of the previous cladding board to the top of your wall, ensuring to include the 30mm overlap.

Leave enough space for a 10mm ventilation gap between the boards and the underside of the soffit. Once the last board is cut to size, install exactly as before using 39mm fibre cement screws with colour-matching heads.

Top tip: Check the installation with a spirit level every four rows to ensure the angle and level of each board is maintained throughout.

Finishing Around Doors and Windows

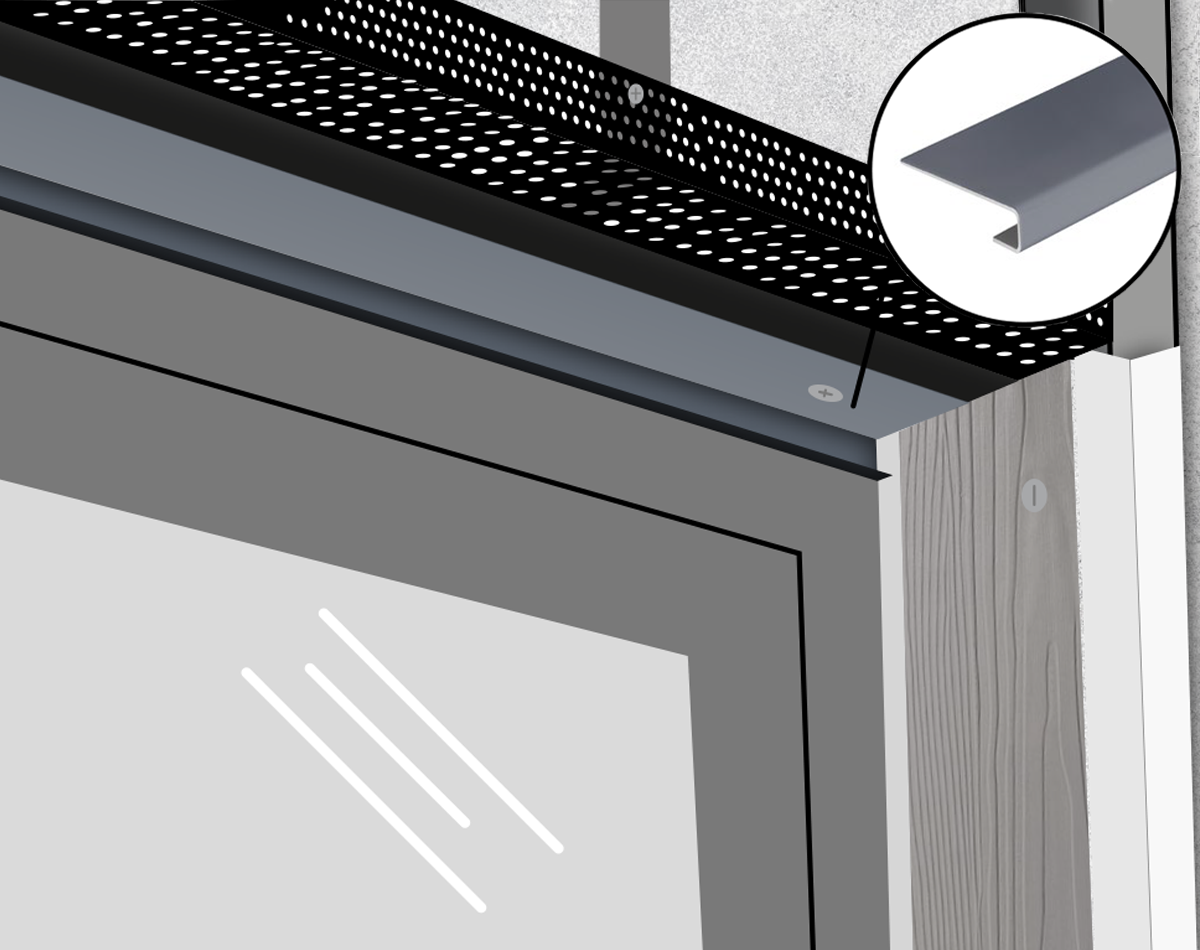

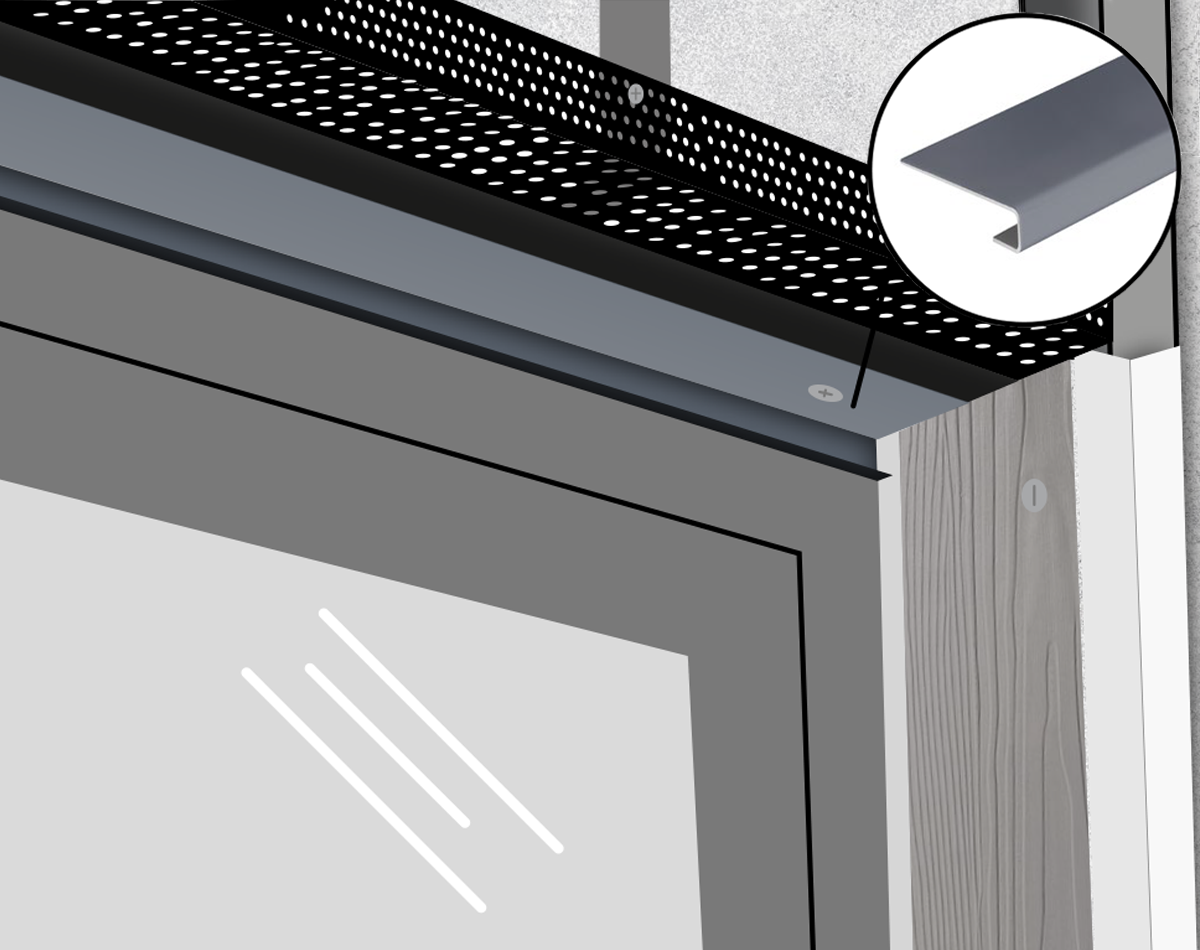

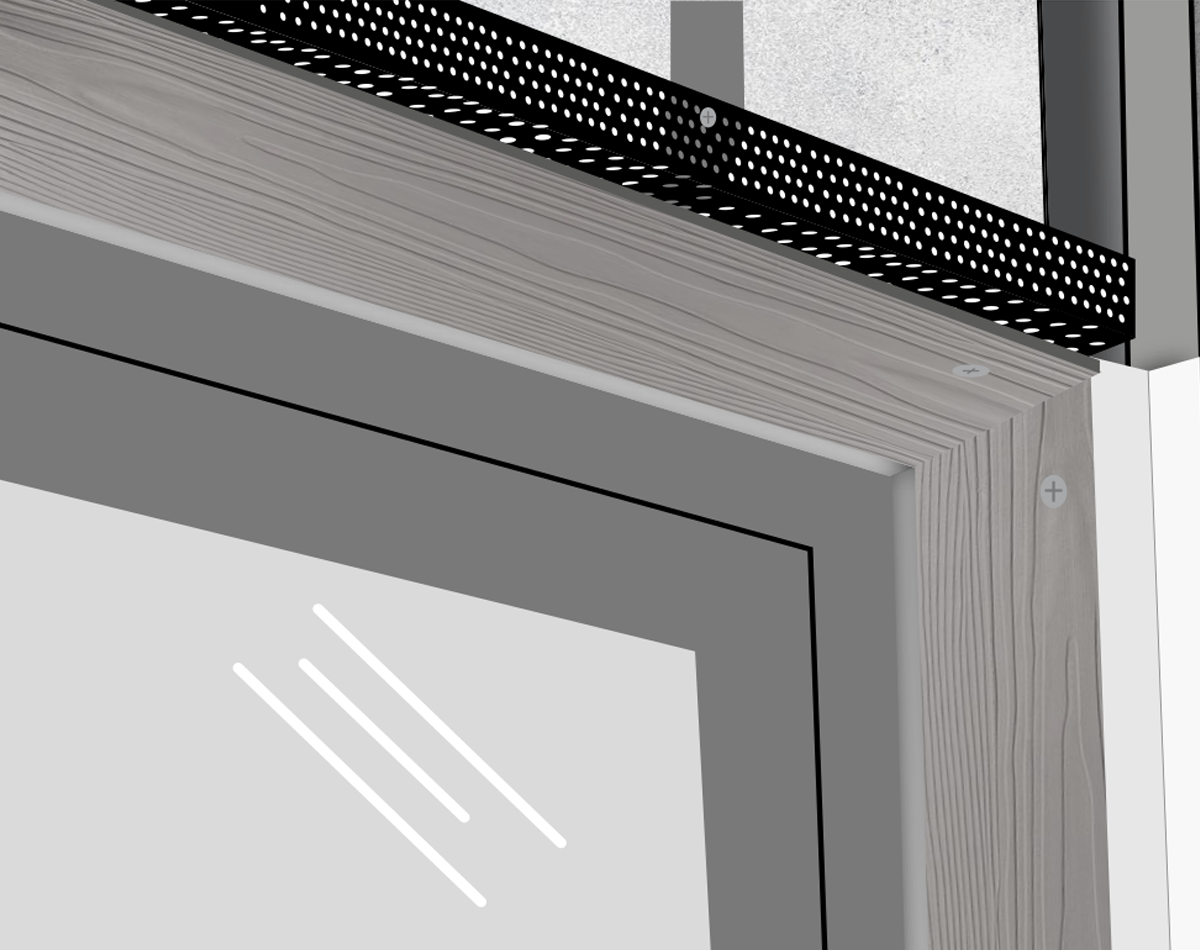

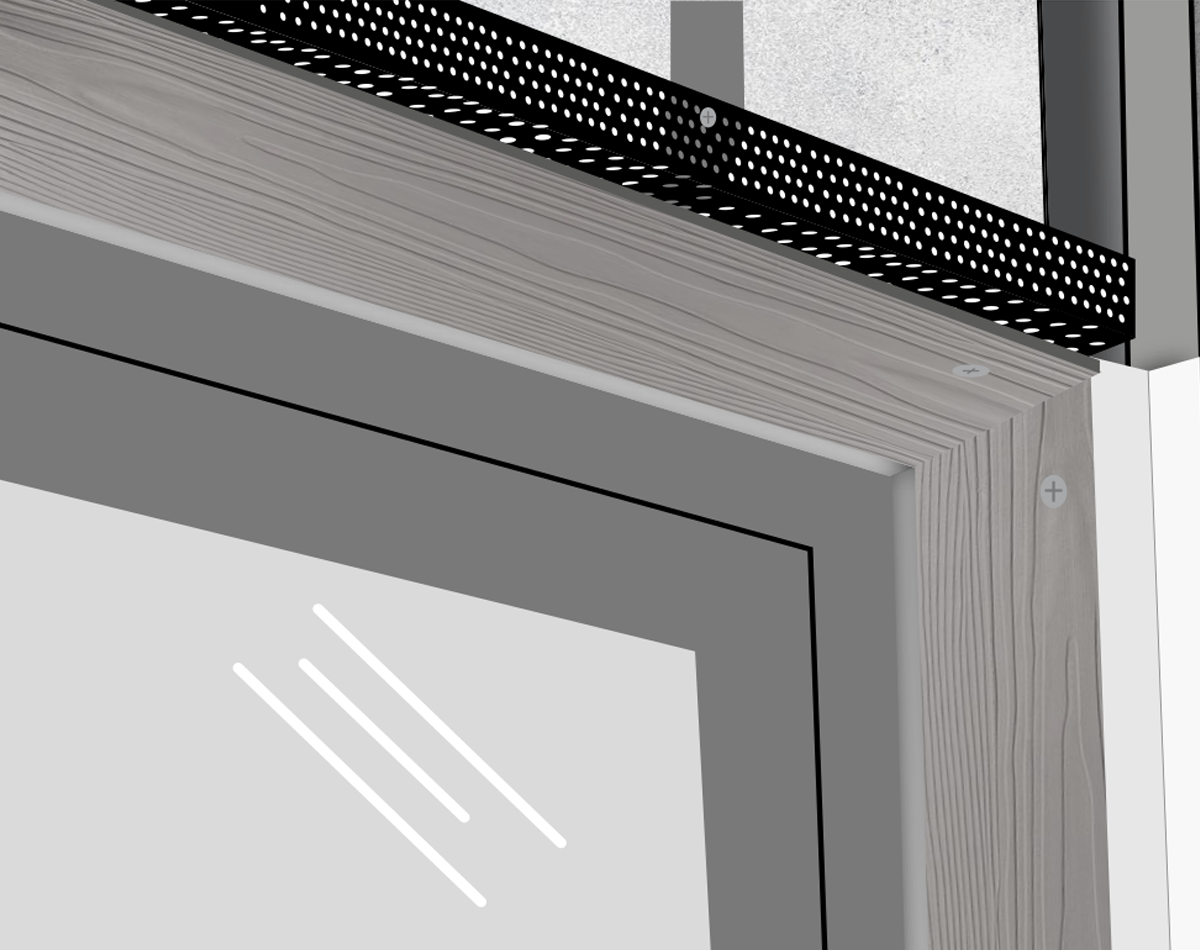

The battens above the windows or doors will need to be installed as per step one with the perforated closure cut to the same length as the top section of a window or door frame and installed underneath the fibre cement lap cladding boards above the windows or doors.

If fibre cement lap wall cladding boards need to be trimmed and cut to fit around doors and windows, measure the space needed and cut the boards to length. Be sure to wear a level P3 respiratory protective mask when cutting the boards.

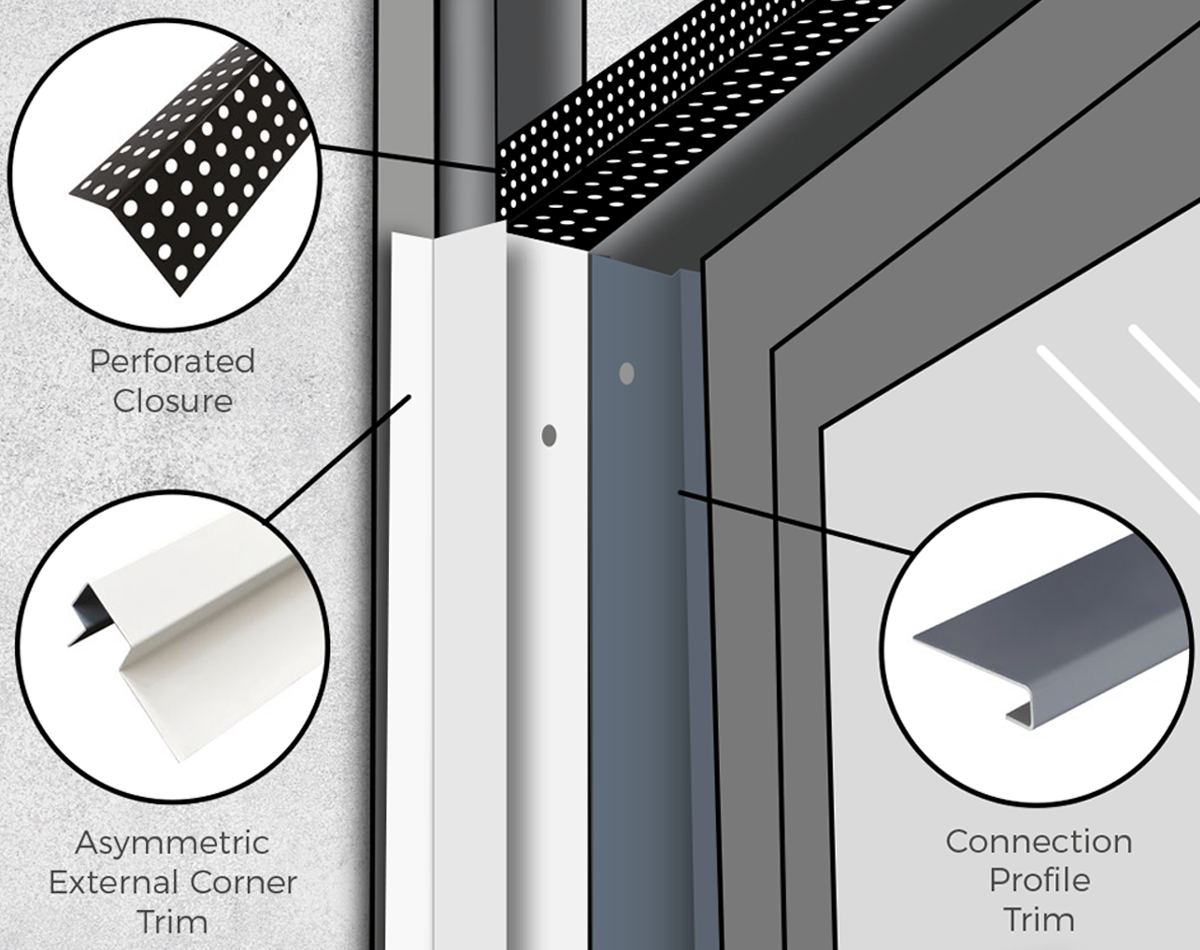

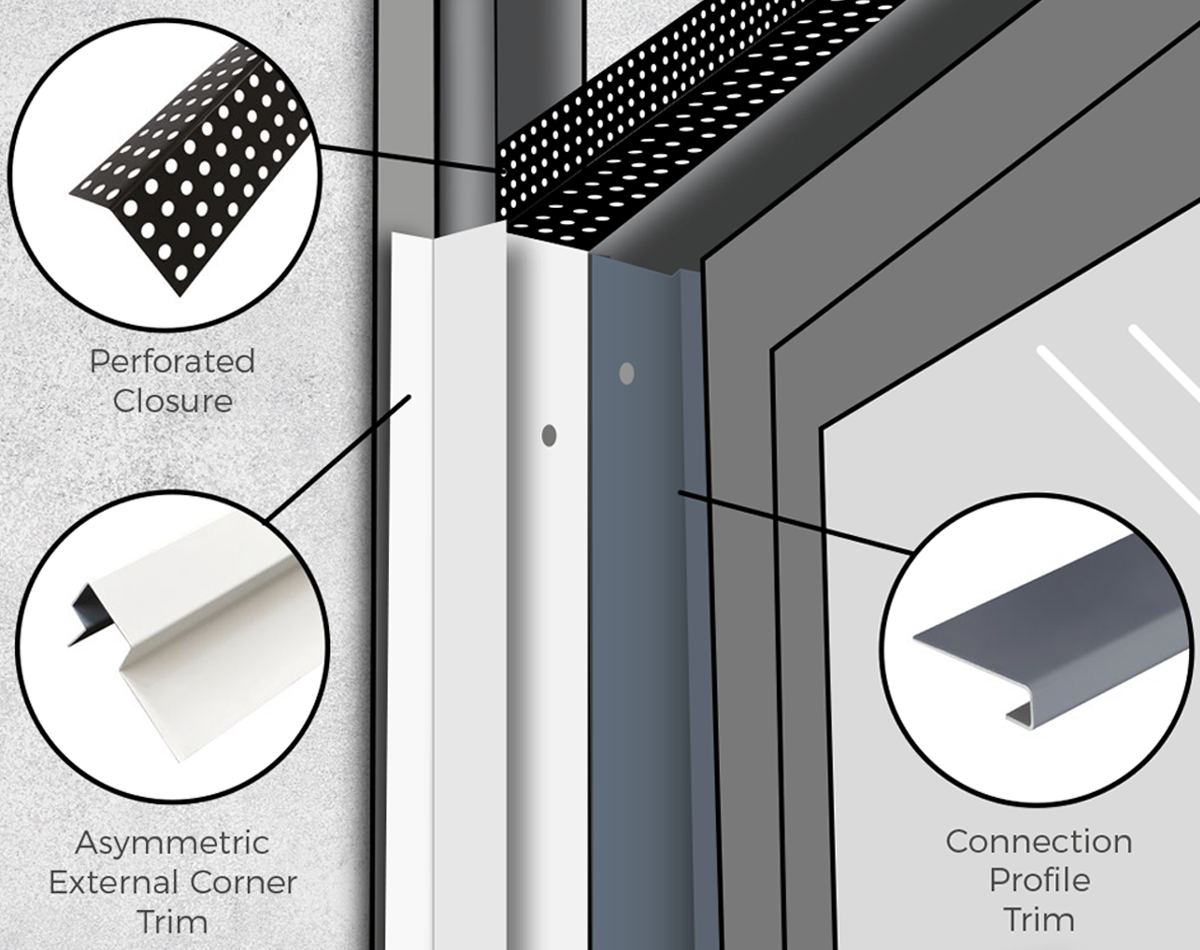

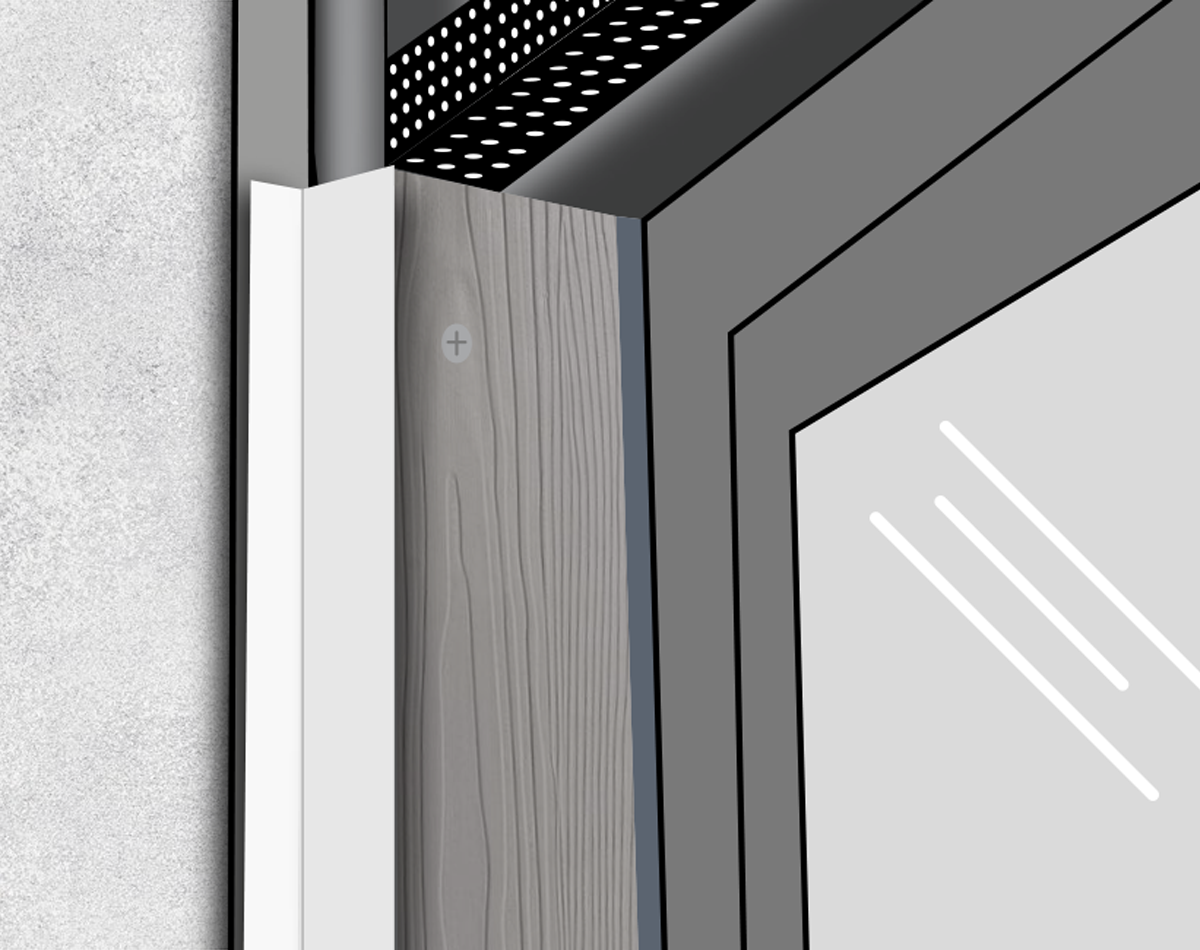

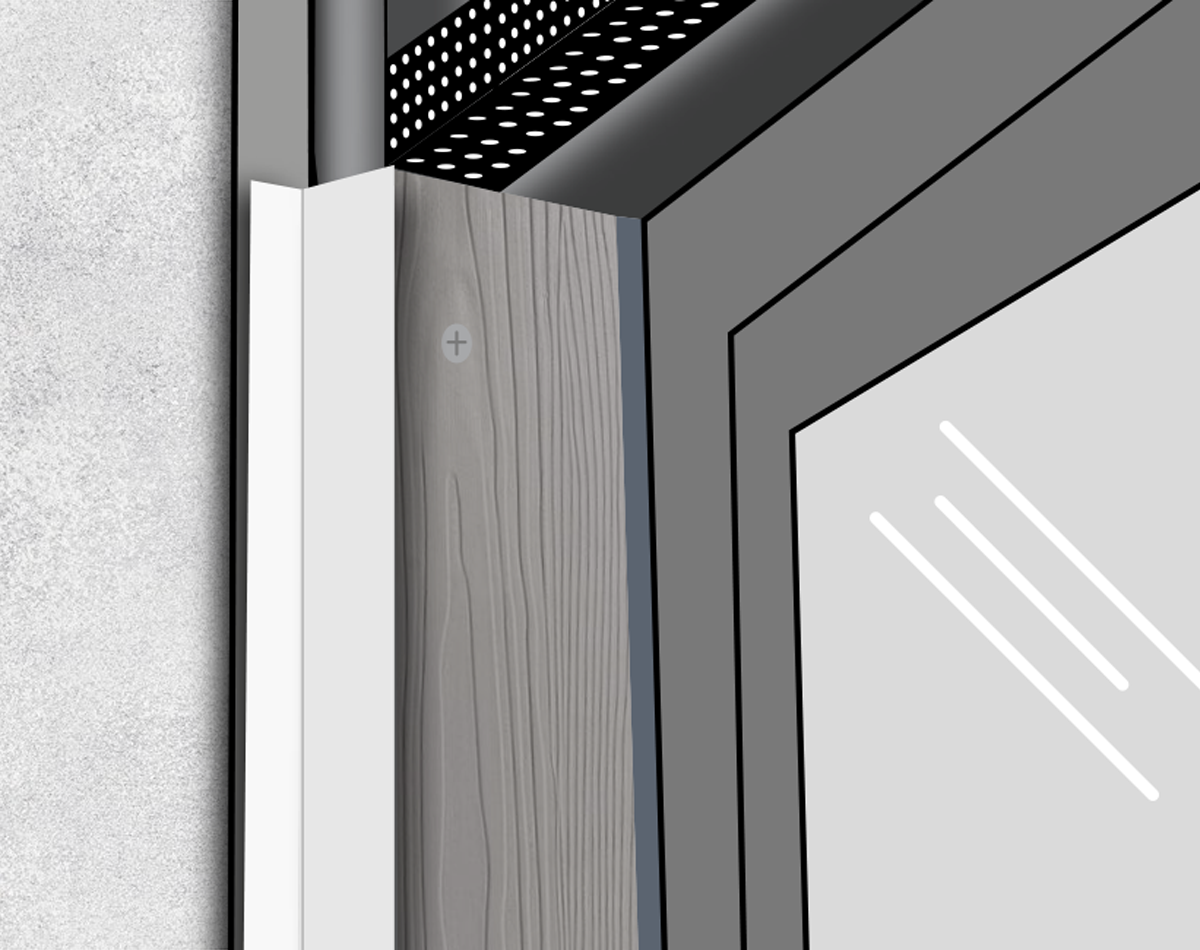

Before the wall cladding can be installed around any windows or doors, asymmetric external corner trims must be fixed to the battens, fitted using 39mm fibre cement screws with colour-matching heads at regular intervals. If your doors, windows or walls require bespoke trims, these are fitted here instead of the asymmetric external corner trims.

Once installed correctly the wall cladding boards can be fitted onto the asymmetric external corner trims. Secure the cut-to-size boards using 39mm Screws.

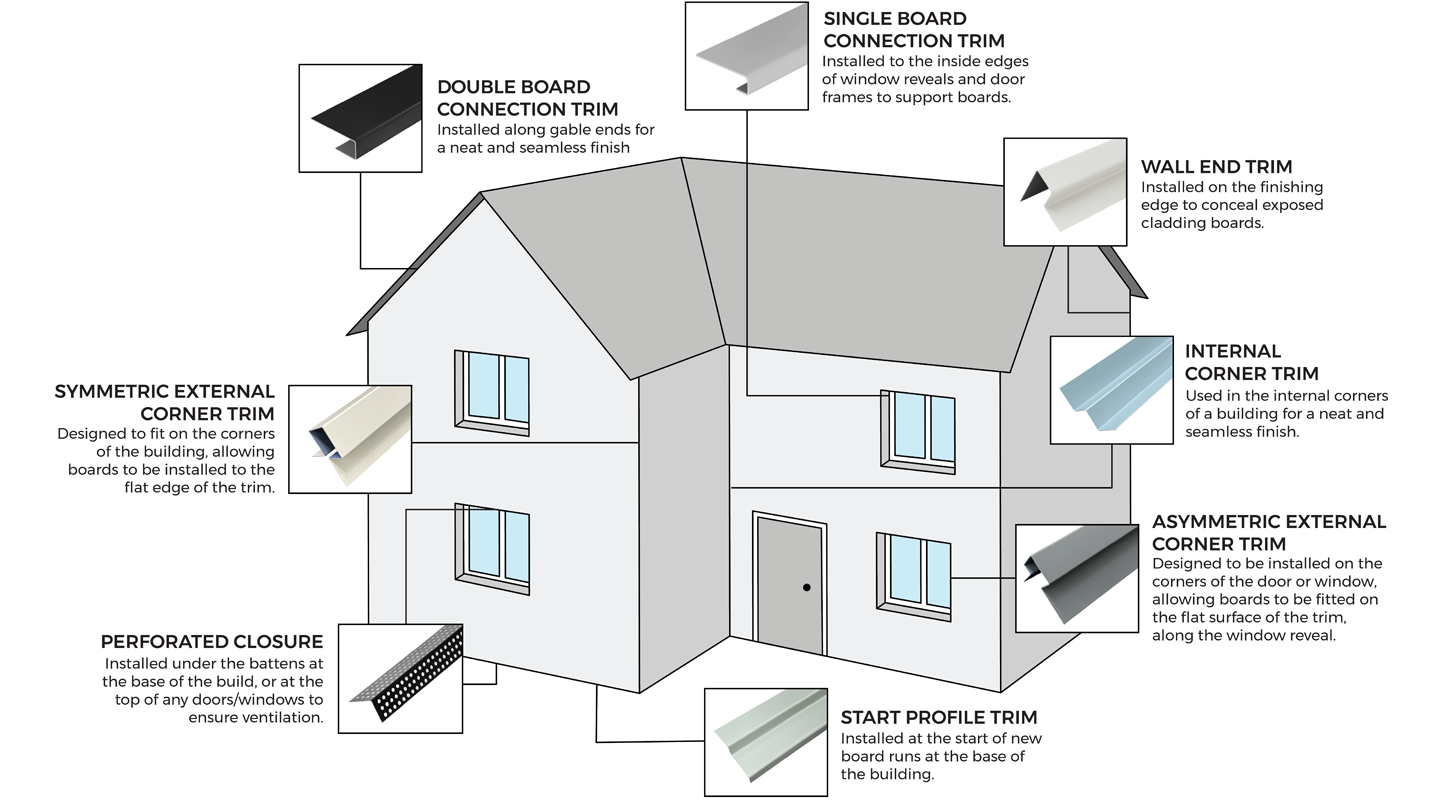

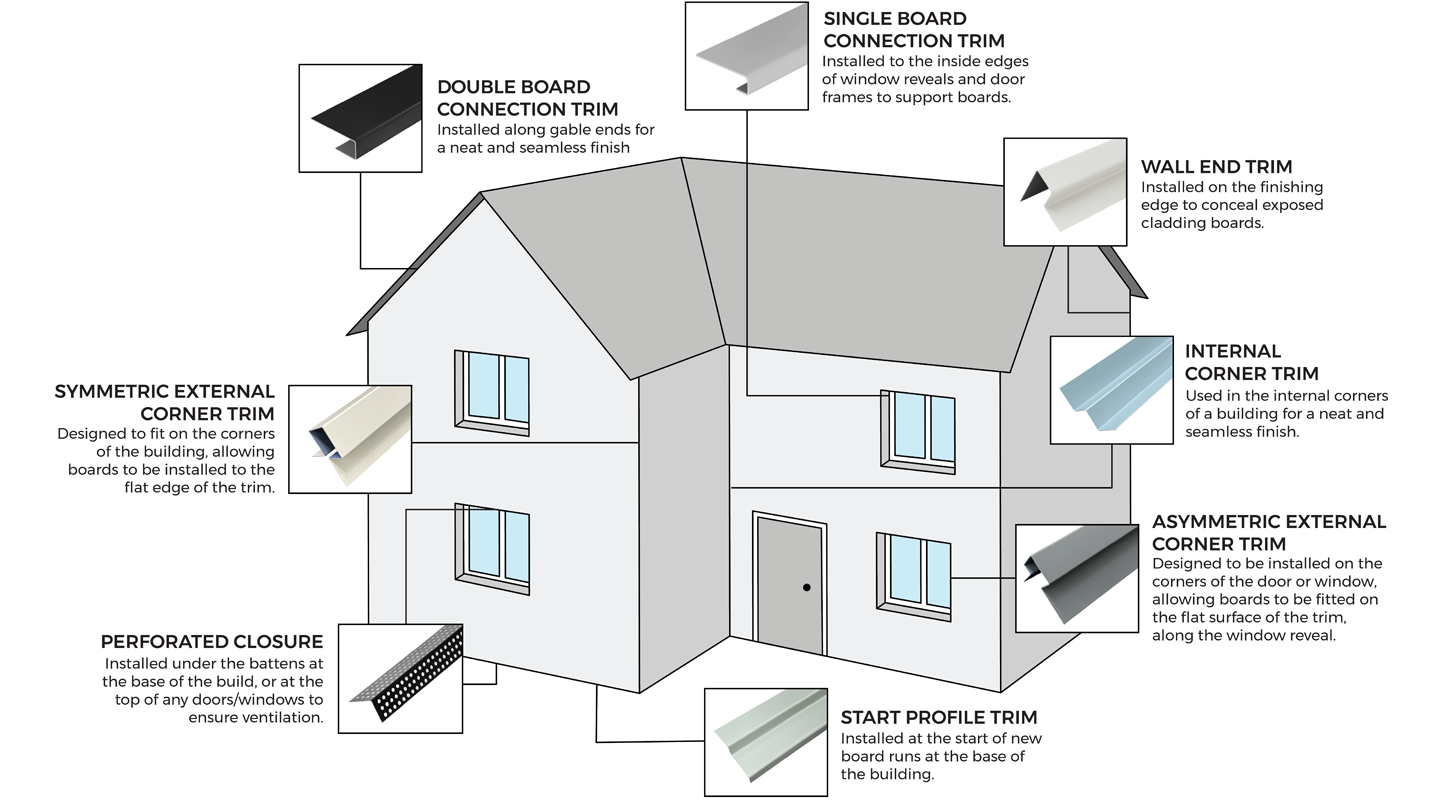

Installing Fibre Cement Lap Trims

1

Perforated closures must be installed before the trims. Start by measuring the width of the top and bottom of the walls and windows, as well as the width of any doors. Cut the perforated closure to the correct lengths using Cladco straight cut tin snips. Using 39mm fibre cement screws with colour-matching heads, fix the perforated closure onto the battens along the top and bottom of the walls, windows and the top edge of any door frames.

2

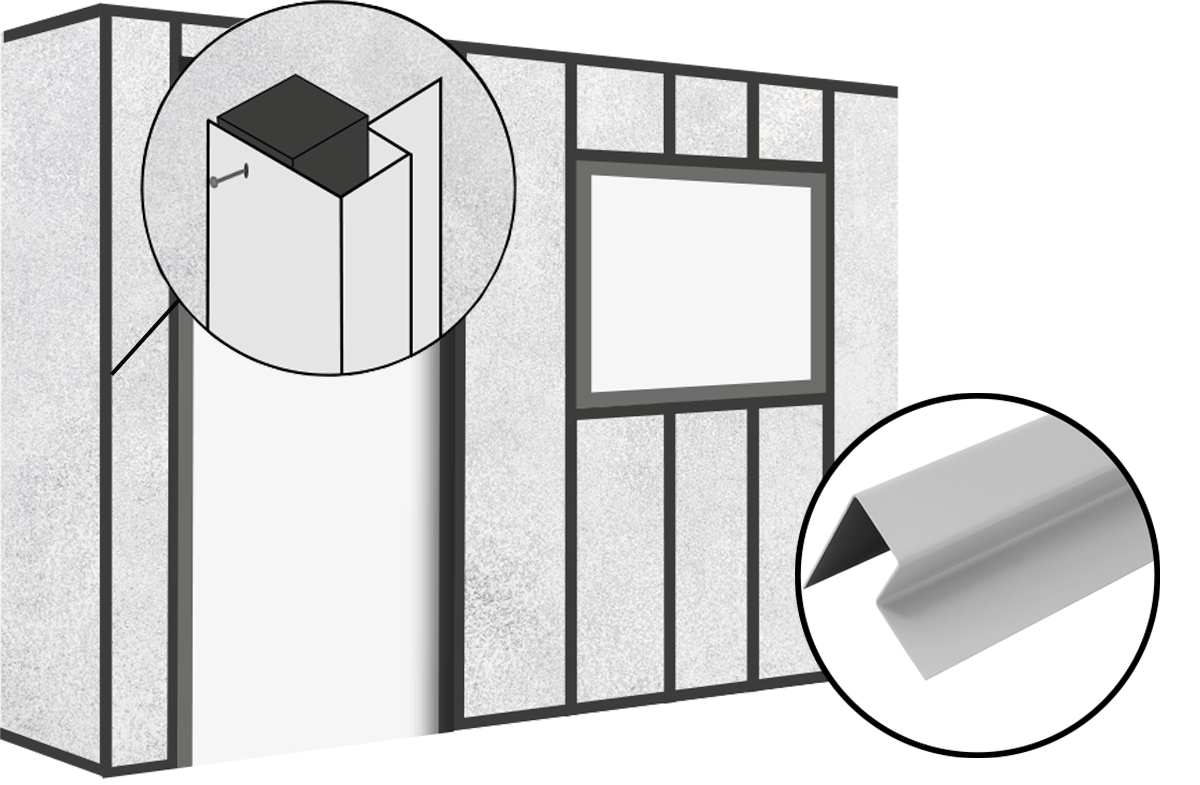

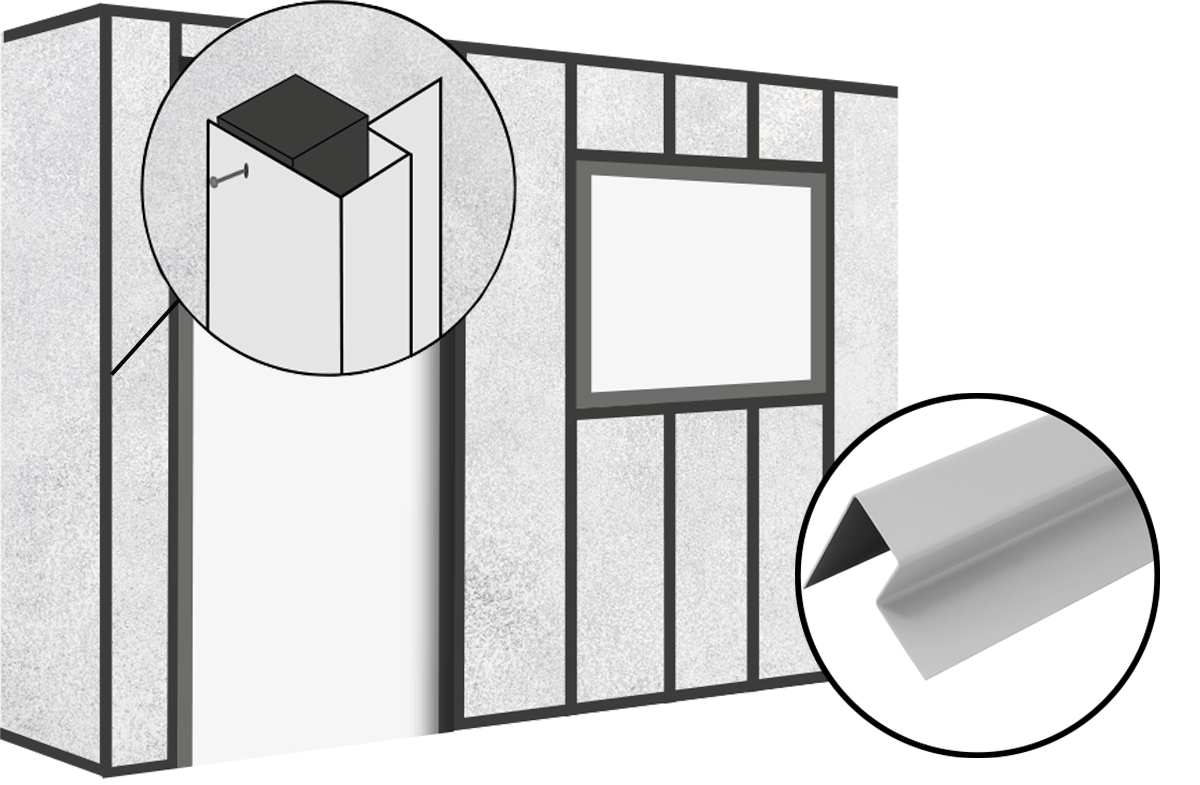

Measure the height of all external and internal corners of your building, as well as the height of windows and doors. Once measured, use Cladco straight cut tin snips to cut the symmetric corner trims (for external wall corners), asymmetric external corner trims (for external window and door corners), and internal corner trims (for internal wall corners) to the correct sizes. Use 39mm screws to install each of the corner trims into place.

3

Measure the height of the battens along the outer edge of your fibre cement wall cladding installation and cut the wall end trims to matching lengths. Fix the wall end trim on top of the batten using 39mm fibre cement screws with colour-matching heads before installing boards.

4

Measure the length of the base of your wall and cut the start trim to the correct size using Cladco straight cut tin snips. Using 39mm screws, secure the start trim over the top of the perforated closure and overlap the external and internal corner trims installed in the previous steps. Leave at least a 10mm gap from the base of the wall to the start trim.

Installing Trims Around Windows and Doors

1

Alongside the asymmetric external corner trims previously installed around windows and doors, secure connection profile trims to the internal corners of a window or door reveal using 39mm screws, as shown in the diagram. Make sure that the small painted edge of the connection profile trim sits neatly against the window or door frame.

2

Cladco fibre cement lap boards can be cut to the same width as the window or door reveals using a wet saw and a level P3 respiratory protective mask. Slot the board between the connection profile trim and the asymmetric external corner trim. Use 39mm fibre cement screws with colour-matching heads to fix the boards into place.

3

Measure a connection profile trim to fit the top internal corner of a window or door head. Cut the connection profile trim using Cladco straight cut tin snips and secure into place using 39mm screws. This will provide adequate support for the overhanging fibre cement lap board under the window or door head.

4

Measure and cut the fibre cement lap board in the same way as before and secure the fibre cement lap board in place using 39mm fibre cement screws with colour-matching heads. Make sure there is at least a 20mm gap between the edge of the board and the perforated trim to allow for adequate airflow.

5

Before installing the next fibre cement lap board above a window or door frame, a section of the board matching the width of the window or door frame will need to be measured and cut using a wet saw. Once cut, secure the board in place using 39mm screws into supporting battens.

Aftercare

MAINTAINING YOUR FIBRE CEMENT LAP CLADDING

Ensure your boards are kept clear of debris and dirt by cleaning with lukewarm or cold water. A mild, household dish soap can be added for more stubborn stains such as bird droppings.

MOULD AND MILDEW

Mildew and algae are common to outdoor products but will not penetrate fibre cement lap cladding boards. Ensure the boards are kept clean of dirt, pollution and other stains by checking them seasonally and giving them a quick clean when necessary.

PAINTING YOUR CLADDING BOARDS

Cladco fibre cement lap wall cladding boards are painted using a paint-and-bake method to give them their durable properties and unique look. However, the boards can be painted with a suitable outdoor paint for an alternative colour. If you are wishing to paint the cladding boards, it is recommended to purchase the unpainted fibre cement lap cladding board.

PRESSURE WASHING YOUR CLADDING BOARDS

Important: do not use high-pressured cleaning systems on Cladco fibre cement lap wall cladding boards as this may cause damage to the paint and finish of the boards.

FAQs

Where can I install my fibre cement lap cladding boards?

fibre cement lap wall cladding boards can be installed on any interior or exterior surface with the correct support structure on garages, sheds, houses, or garden rooms.

Can I use a pressure washer?

Pressure washers are not recommended to be used on Cladco fibre cement lap wall cladding boards as the pressure could strip the boards of their paint layers and properties.

Simply clean using lukewarm or cold water and light detergent with a cloth or soft brush.

What is dimensionally very stable?

Cladco fibre cement lap wall cladding boards, like any material exposed to sunlight over a prolonged period of time, will get warmer. Like most materials, when Cladco fibre cement lap wall cladding boards change temperature, slight expansion or contraction within the boards can occur. These changes are minimal compared to alternative products on the market.

Can Cladco fibre cement lap wall cladding boards be installed vertically?

Cladco fibre cement lap cladding boards cannot be installed vertically.

fibre cement lap boards are designed to be installed horizontally using a feathering technique, giving your building an attractive finished appearance.

Installing the boards vertically is not recommended by Cladco Profiles as detailed in Cladco terms and conditions.

Can Cladco fibre cement lap wall cladding boards be painted?

Cladco fibre cement lap wall cladding has been painted using a paint and bake method which gives the boards increased durability and strength. boards can either be painted an alternative colour (if you are doing this, we recommend purchasing the unpainted board) and can be touched up if necessary using Cladco fibre cement lap touch up paint.

Are the boards scratch resistant?

Cladco fibre cement lap wall cladding boards, thanks to their three layers of baked paint, have increased scratch resistance properties. The baked paint increases the boards’ durability, however boards may still scratch if handled incorrectly.

What colours are available?

Cladco fibre cement lap cladding boards are available in eight colours and an unpainted board.

Can I order a Sample?

Cladco fibre cement lap wall cladding samples can be ordered via the website, or by contacting our friendly sales team on 01837 659901.

You can choose two of the nine available options above to sample. The Sample Swatches come with a Cladco decking brochure and a price list.

Why are white marks appearing on my fibre cement lap Cladding?

Efflorescence occurs naturally when moisture interacts with fibre cement lap products. Store boards indoors and avoid installing when wet. Proper airflow and ventilation are essential to minimise this occurrence.