Choosing the right roof covering for your garage, shed, garden room, or outbuilding can feel a little daunting, especially with so many styles and finishes to pick from.

At Cladco, we manufacture and supply an extensive range of roofing sheets in different profiles, thicknesses, and coatings. One of the most common questions we hear is: “What’s the difference between PVC and polyester finishes?”

And honestly, it’s a fair question.

Before getting into the differences between finishes, though, the first step is usually to decide on the overall look you’d like to achieve. Are you drawn to the timeless style of pantile-effect sheets, such as our tile form roof sheets, the industrial feel of 32/1000 box profile, or perhaps the more traditional appearance of corrugated or 34/1000 box profile sheets?

If you’re still unsure, our image gallery is a great place to explore what other Cladco customers have managed to create with our metal roof sheets.

Once you’ve chosen your sheet profile, the next decision is which finish is right for you: polyester paint or PVC plastisol (with the exception of tile form and standing seam sheets, which come with a premium GreenCoat® Pural finish). Understanding the difference between these options will help you find the perfect match for your project.

PVC Plastisol coated sheets

When it comes to metal roof sheet coatings, PVC plastisol is certainly one of the most durable finishes you can choose. With a lifespan of 15–25 years before maintenance is required, PVC plastisol-coated sheets can often last well over 40 years. This reliability makes them a very popular option for projects where longevity is a key priority. It is important to remember, however, that in coastal areas or more exposed areas of the country, the timeframe before maintenance is likely required may be shorter.

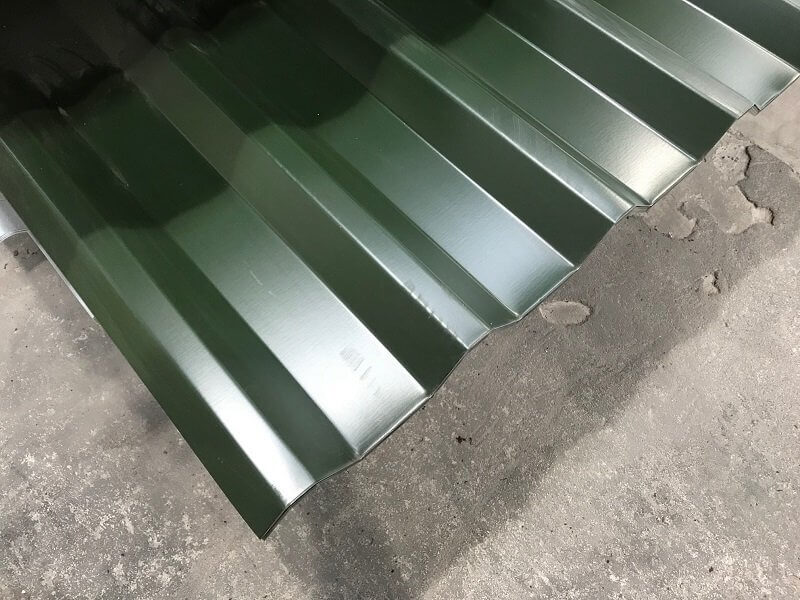

The coating itself is tough and resilient, made from polyvinyl chloride-based thermoplastic resins designed with UV resistance in mind. Our PVC plastisol-coated sheets are primed before 200 microns of leather-grain embossed plastisol are applied to the external face. On the reverse of the sheet, the surface is galvanised and finished with a protective grey alkali wash coat. This combination gives excellent resistance to scratches and wear, making PVC plastisol a popular choice across the construction sector.

So, if you’re looking for a premium, long-lasting protective coating for your metal roof sheets, PVC plastisol is the way to go. These sheets come in a wider range of colours than polyester-coated sheets, giving you greater flexibility when it comes to design. While polyester painted sheeting may be the more budget-friendly choice upfront, the added durability and reduced maintenance of PVC plastisol often prove more cost-effective in the long run.

Polyester Paint coated sheets

Polyester paint-coated sheets are a more cost-effective option, providing a neat and practical finish for many projects. With a typical lifespan of 8–12 years before the first maintenance is needed, they can last over 20 years in standard environments. However, compared with PVC plastisol, this is a less durable finish, so you’ll need to factor in upkeep sooner.

Each sheet is primed and coated with 25 microns of high-grade polyester enamel paint on the external face, while the reverse side is galvanised and finished with a protective grey alkali wash coat. This process gives reliable protection, though the coating has lower resistance to scratches and wear, so care is needed during installation. To minimise the risk of marks in transit, we deliver polyester sheets with a protective cover sheet.

Polyester-coated roofing sheets are available in a smaller colour range than PVC plastisol, with options including juniper green and light grey, ideal if you want your roof to blend seamlessly with surrounding buildings or the landscape. If aesthetics are a major factor in your project, though, just bear in mind that the colour choice here is more limited.

GreenCoat® Pural BT coated sheets

While the original question may have been “what’s the difference between PVC and polyester finishes?”, there’s a third option worth considering: GreenCoat® Pural BT. This premium coating is built for durability as well as environmental performance. In normal conditions, Pural BT-coated sheets can last up to 40 years, offering significantly longer protection than other finishes.

Available in tile form and standing seam profiles, GreenCoat® Pural BT sheets come in four distinctive colours: Nordic night black, slate grey, tile red, and silver fir green. Each sheet has a 50-micron Pural BT layer, engineered to resist scratches, UV radiation, corrosion, and dirt build-up, while holding its colour for decades.

What sets this finish apart is its innovative Bio-based Technology (BT), which replaces a substantial portion of fossil oil with Swedish rapeseed oil. Patented worldwide by SSAB, this technology lowers environmental impact while delivering excellent wear and weather resistance.

With its combination of long-lasting performance, eco-friendly credentials, and refined appearance, GreenCoat® Pural BT is the ideal choice for projects where both sustainability and style matter.

Still not sure?

If you’re still unsure which coating is right for your project, why not order some roofing colour swatch samples from our website? Seeing the coatings up close is the best way to compare PVC, polyester, and GreenCoat® Pural BT side by side, and it gives you a true idea of the colour and finish before making your final choice.

Alternatively chat with one of our sales team via email at [email protected] or by calling us on 01837 659901.

Last Updated: September 19, 2025

Please note all information is correct at the time of writing. However, we encourage you to do your own research to ensure it remains accurate and relevant to your needs.