Article Summary:

If you've never tried your hand at sealing a deck before, then we recommend following these simple steps below to help you get it right the first time around. Sealing timber deck boards can help keep them looking as good as new with their original woodgrain surface, and provide further protection from the elements, ultimately extending the life of your deck.

Find out which products make our list of the top five deck sealers and how making the right choice can help protect and enhance your deck. We’ll also explain the key differences between a stainer and a sealer, so by the end of this guide, you’ll have a clear idea of whether staining or sealing is the best option for your decking, and which sealers are worth considering.

Best deck sealers for clear, maximum protection

Not sure which deck sealer is right for you? Don’t worry, we’ve got you covered. Below, we’ve rounded up our top five recommended deck sealers to help keep your timber decking looking its best while protecting it from the elements year after year.

When choosing a deck sealer, you’ll realise that there are a few different types available, including oil-based, cream-based, and water-based options, each with its own advantages.

Oil-based deck sealers are known for their strong protective qualities, especially when it comes to resisting water. They penetrate deeply into the timber, helping to guard against heavy rainfall and moisture damage. Another advantage is their durability, with oil-based sealers typically lasting longer than water-based alternatives.

However, there are some downsides to consider. Application can be trickier, and many oil-based sealers contain chemicals that are less environmentally friendly. They also take longer to dry, so you’ll need to plan ahead when using this type of sealer.

Water-based sealers are a much more eco-friendly and safer solution. Using this type of sealer also tends to result in far less mess and is quicker drying than oil-based sealers, too. However, water-based sealers are less durable than oil-based alternatives and may need reapplication more frequently.

1. RONSEAL ULTIMATE PROTECTION DECKING OIL, 5 LITRES

This oil-based decking sealer is designed to provide your deck with long-lasting protection while enhancing its natural look. Specifically for oak decking, Ronseal Ultimate Protection Oil penetrates deep into the timber to boost durability and provide resistance against both weather and heavy foot traffic. A key advantage over standard sealers is its built-in UV protection, helping to prevent fading and keep your deck looking fresh for longer.

Shop for Ronseal Ultimate Protection Decking Oil on Amazon.

2. ROXIL WOOD PROTECTION CREAM, 3 LITRES

As opposed to oil-based sealers, Roxil Wood Protection Cream works after just one coat, and according to Roxil, it will provide weatherproofing for over 10 years. Apply to hardwoods or softwoods to help reduce mould, warping and algae from occurring on the deck surface.

Shop for Roxil Wood Protection Cream on Amazon.

3. EVERBUILD WOOD PRESERVER, 5 LITRES

This wood preserver boasts a fast-drying time and aims to give lasting protection from wet rot, fungi and decay for various wood surfaces. Everbuild Wood Preserver is solvent-free and non-flammable, making it versatile and safe for both indoor and outdoor use. It can even be applied to damp wood.

Shop for Everbuild Wood Preserver on Amazon.

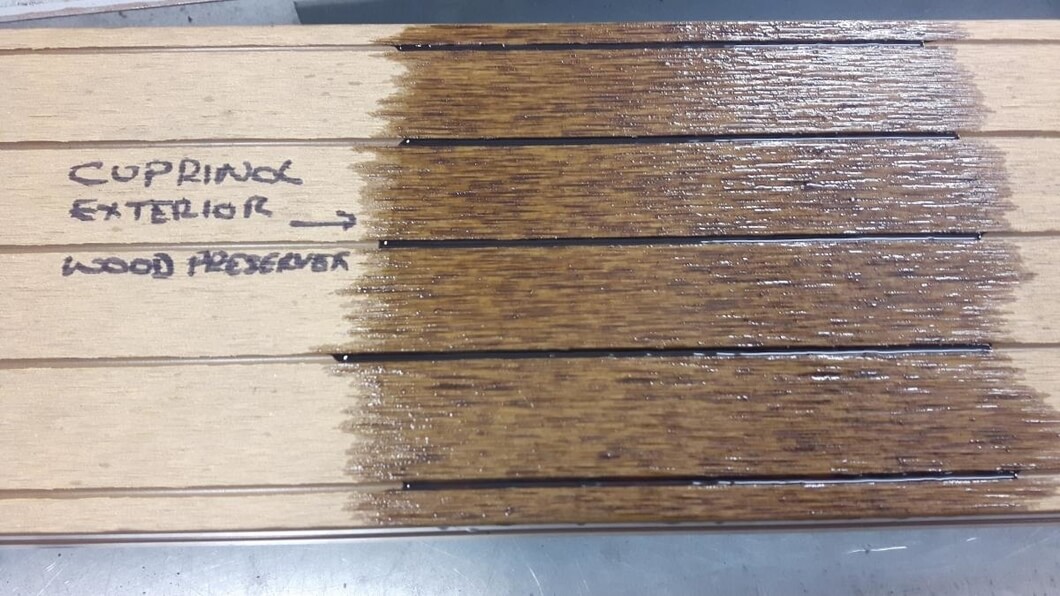

4. CUPRINOL WOOD PRESERVER, 5 LITRES

Cuprinol Wood Preserver is the best clear deck sealer currently out there on the market, designed for application on pressure-treated wood and for both exterior and interior types of wood. Apply this preserver before painting, staining or varnishing your deck to protect against decay, rot and mould.

Shop for Cuprinol Wood Preserver on Amazon.

5. BARRETTINE DECKING OIL, 5 LITRES

Barrettine Decking Oil is a unique formula in that it offers additional anti-slip properties for the surface of your deck. Available in a clear finish, the product increases UV protection and reduces the water absorption rate for decks.

Shop for Barrettine Decking Oil on Amazon.

What to think about when deciding on a deck sealer

When selecting the best sealer for your deck, there are several factors you need to keep in mind. The type of wood decking you’ve installed is crucial, as different timbers not only respond better to certain products but may also have unique needs depending on their environment. For instance, pressure-treated wood often requires a reliable decking sealer to provide extra protection against heavy rainfall and long-term exposure to the elements.

Price: Cream-based sealers are generally more expensive than oil-based sealers per gallon due to the fact that they require fewer coats each time and dry quicker. Water-based sealers are again more expensive than other sealers.

Toughness: Some of the best deck sealers are often oil sealers, which are either clear or semi-transparent in appearance. The properties of those sealers, after a second coat, can help prevent water damage or moisture building up in the boards caused by heavy rain.

Eco-friendliness: It's no secret that water-based sealers are the safest deck treatment type for the environment, containing fewer chemicals that could affect the surrounding environment. Check the formulas of other sealers and apply them carefully to surfaces to reduce the risk of affecting the environment.

Ease of use: The easiest sealers to apply are water-based and cream-based ones, due to their faster drying times within 24 hours. Water sealers are generally applied using a brush, although you can use a sprayer for quicker application. Oil sealers are usually applied with a paintbrush for each coating. It's important when deck treating to make sure the wood is fully dry for the best quality results.

Resistance properties: Protecting boards from UV rays is an important consideration to prevent fading or cracking. Sealers come with a slight amount of protection, although this varies depending on the pigmentation of the sealer. Other sealers offer mould and mildew protection, with moisture prevention to enhance longevity.

Drying times: Deck sealer dry times vary, with water-based sealers usually dry to the touch within just a few hours in warm daytime temperatures. This allows you to apply a second coat for added protection for the exterior wood surface. Oil sealers can take twice as long to dry, with cure times of 72 hours. One coating is usually not enough, so make sure you have a few days of sunshine when applying this type.

Do you need to seal composite decking?

Composite decking is designed to be a low-maintenance solution, made from a blend of recycled hardwood fibres and plastics, enhanced with colour tints and dyes. The colour runs throughout the board rather than sitting only on the surface, helping to maintain its appearance over time.

Unlike natural timber, composite decking doesn’t need sealing. Each board is manufactured to resist weathering, UV rays, insects, and rot, so there’s no need for additional treatments.

Whether installing Signature or ProDeck composite decking, a simple occasional wash is all that’s required to keep your deck looking its best. That means more time enjoying your outdoor space, and less time maintaining it.

What's the difference between deck sealer & stain?

Sealer

A deck sealer is typically an oil-based treatment, and it works by penetrating the timber to create a protective layer that reduces water absorption. This not only helps prevent mildew, mould, and rot from damaging your deck boards but also enhances the natural grain of the wood.

However, because sealers are usually clear, they provide little protection against harmful UV rays. Over time, this lack of UV resistance can cause the wood's natural oils to dry out, increasing the risk of cracking or splitting if the deck is left untreated.

Stain

A deck stain protects the timber from both water absorption and harmful UV rays, thanks to the pigments contained within the formula. As a rule, the darker the stain, the greater the level of UV protection it provides.

Unlike clear sealers, stains also add colour, giving you a wide choice of finishes to complement your decking. This not only enhances the wood's appearance but also provides an extra layer of defence against fading and sun damage.

How to apply deck sealer to a wood deck

Sealing a deck can help to extend the lifespan of the deck area and ensure it effectively reduces the level of water absorption into the wood surface. There are quite a few points to consider first before jumping into the process.

STEP 1: CHECK THE WEATHER FORECAST

Before you reach for your paintbrush, it's always a good idea to take a moment to check the weather. You'll need several days of dry conditions to give the deck sealer time to fully cure. Avoid sealing in hot, direct sunlight, as this can cause the product to evaporate before it properly soaks into the timber. And if it rains before the sealer has dried, you may find yourself starting over, or at the very least waiting much longer for the finish to set.

STEP 2: CLEARING YOUR DECK BEFORE SEALING

Before applying any type of deck sealer, make sure the surface is completely clear. Remove furniture, plant pots, and any obstacles or debris. This way, you won't have to move things around while the sealant is being applied or drying, helping you achieve an even, uniform finish.

STEP 3: SAND YOUR DECK (IF REQUIRED)

Sanding your decking boards isn't always necessary, but it can help if your deck has been previously treated or varnished. Sanding opens up the surface of the timber, improving absorption of the stain or sealer. If you do sand, always work in the direction of the wood grain for the best finish. Keep in mind that this step can be time-consuming, so weigh it up carefully if the weather window is limited.

STEP 4: CLEAN & RINSE YOUR DECK

Thorough cleaning of your deck is the most important step to take before any sealing takes place. Make sure the surface is free from mould, mildew, and any dust left behind from sanding, which ensures maximum absorption of the sealer. Always apply sealant to dry boards unless the manufacturer specifies otherwise.

STEP 5: STIR YOUR SEALER

Before you begin, stir the sealer gently to ensure the contents are evenly mixed. Avoid shaking the container, as this can create air bubbles that may affect the finish.

STEP 6: APPLY THE SEALER

Using a brush, pump sprayer, or paint roller, apply a thin, even coat of sealer across the deck, working it thoroughly into the wood. Watch out for any pooling or creamy patches and smooth them out straight away. For best results, build up several thin layers rather than one thick coat. This helps with absorption, reduces drying time, and avoids an uneven finish. Always allow the sealer to dry fully before walking on or using your deck.

CONCLUSION:

Now that you’ve seen the steps involved, sealing your deck doesn’t have to feel like an overwhelming task. With the right preparation and a bit of care, you can protect your boards, extend their lifespan, and keep your outdoor space looking its best for years to come.

Choosing the right deck sealer for pressure-treated wood is the first step to extending the life of your deck. A good sealer prepares the surface for future treatments, whether you plan to paint or stain later on. If your deck is already heavily weathered or worn, applying a fresh coat of paint instead of sealing may be the better option to refresh and cover the surface.

Always make sure you consider the type of wood you’re sealing and the weather conditions, as both will affect drying time. Oil-based deck sealers typically take longer, sometimes up to 72 hours, so it's always a good idea to plan ahead if you can. For the best results, always check the manufacturer’s guidance before purchasing your chosen deck sealer.

Whether you choose a water-based or cream-based wood sealer, it’s crucial you think about the benefits you require, from improved UV protection to added low-slip properties, to get the best results for your deck.

If regular staining and sealing isn’t for you, Cladco also offers a fantastic range of low-maintenance alternatives to timber decking. Our Signature, ProDeck, Nordeck and Millboard decking boards don’t need sanding, sealing, or treating. Simply install them and enjoy a long-lasting deck with minimal upkeep.

Last Updated: September 09, 2025

Please note all information is correct at the time of writing. However, we encourage you to do your own research to ensure it remains accurate and relevant to your needs.