How to Lay Cladco Sheets

After purchasing your Cladco Roofing Sheets it’s imperative that you know which way to lay the sheeting, whether box profile, corrugated or tile effect, the sheets need to be laid in an appropriate order for effectiveness against prevailing wind. It’s advised to lay metal sheets in sets of runs and we advise starting at the eaves and at the corner which is furthest away from the prevailing direction of wind (This is the case for a single run sheet). Installing in this manner helps to prevent any side laps which are facing the wind having water penetrate.

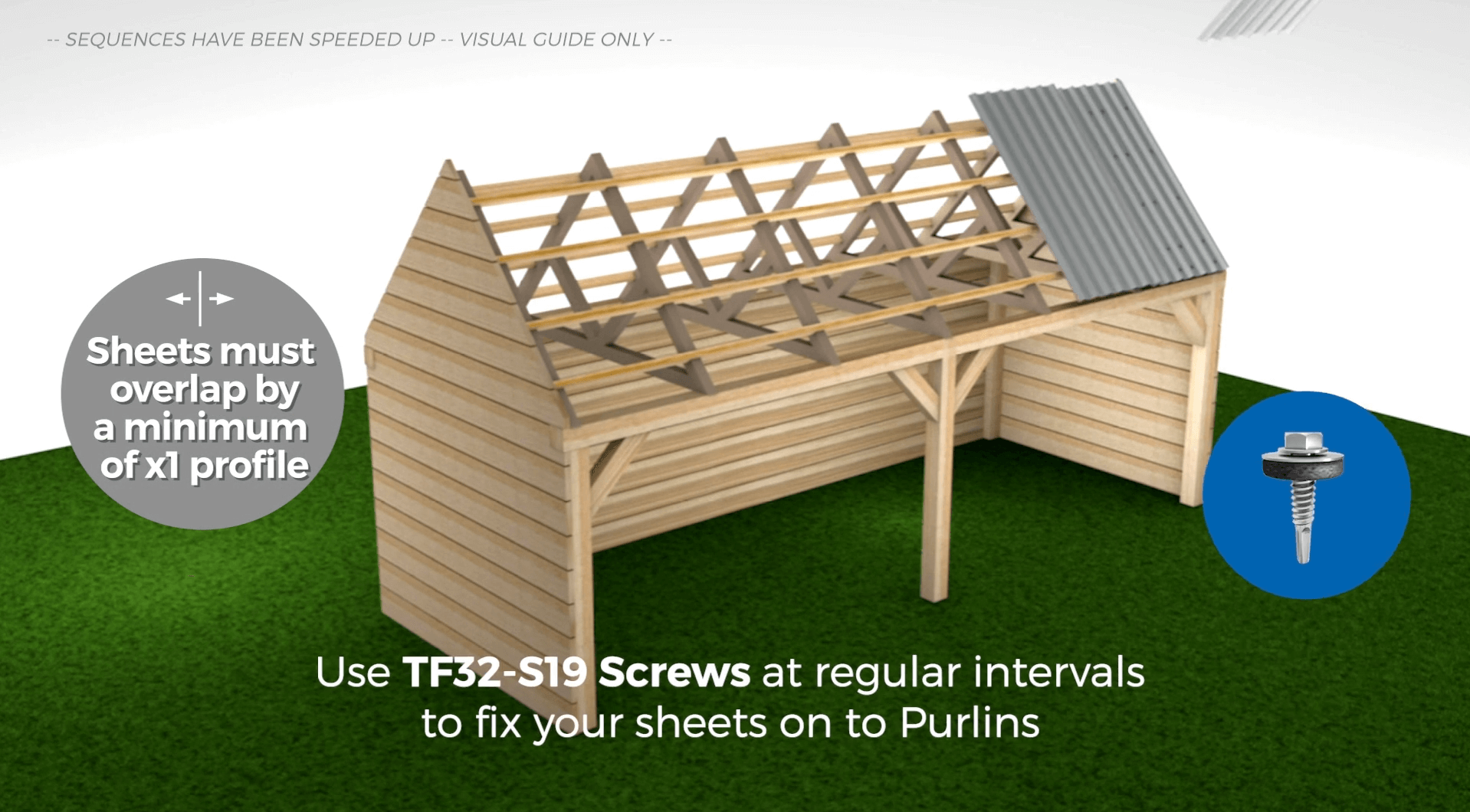

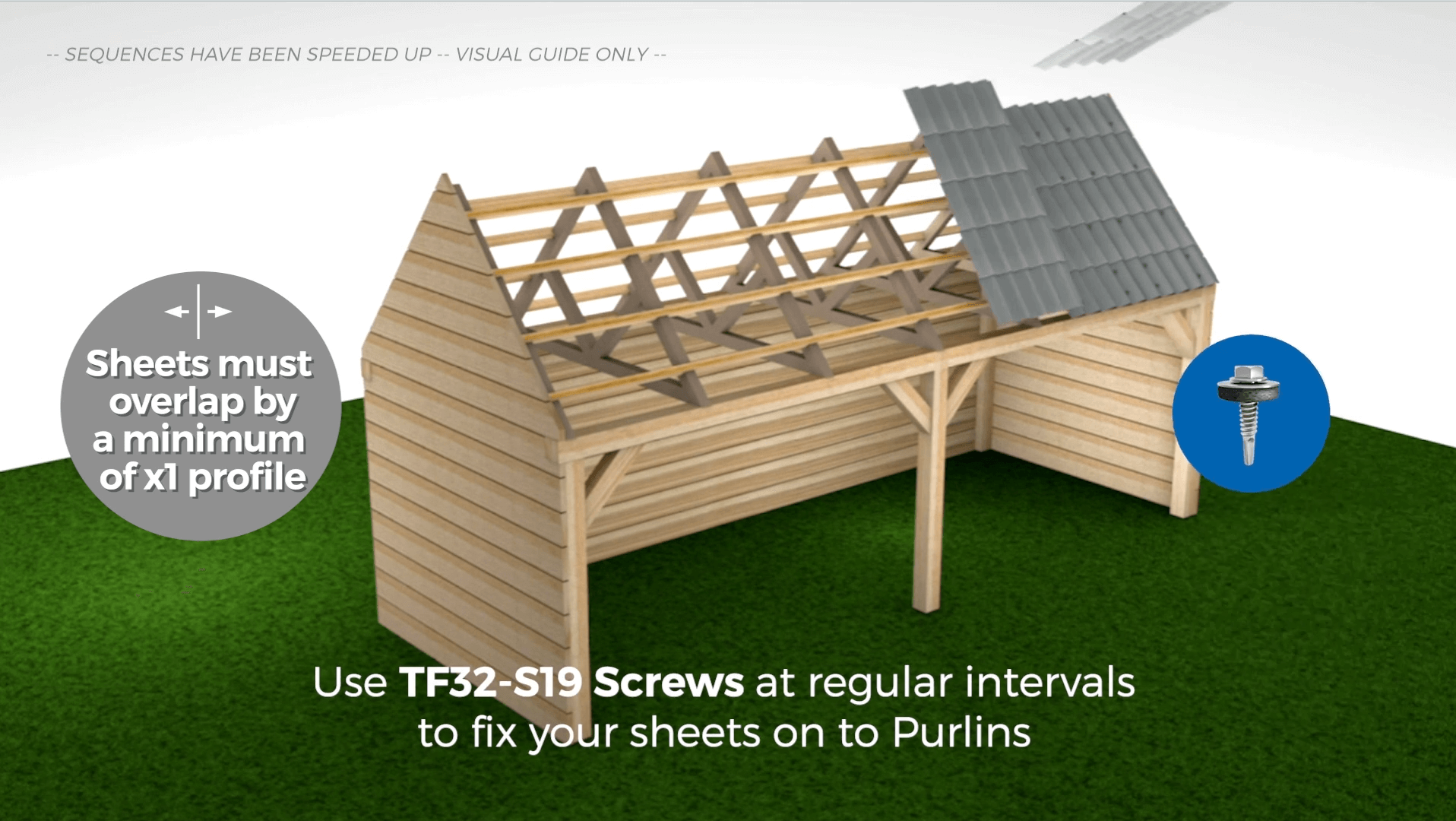

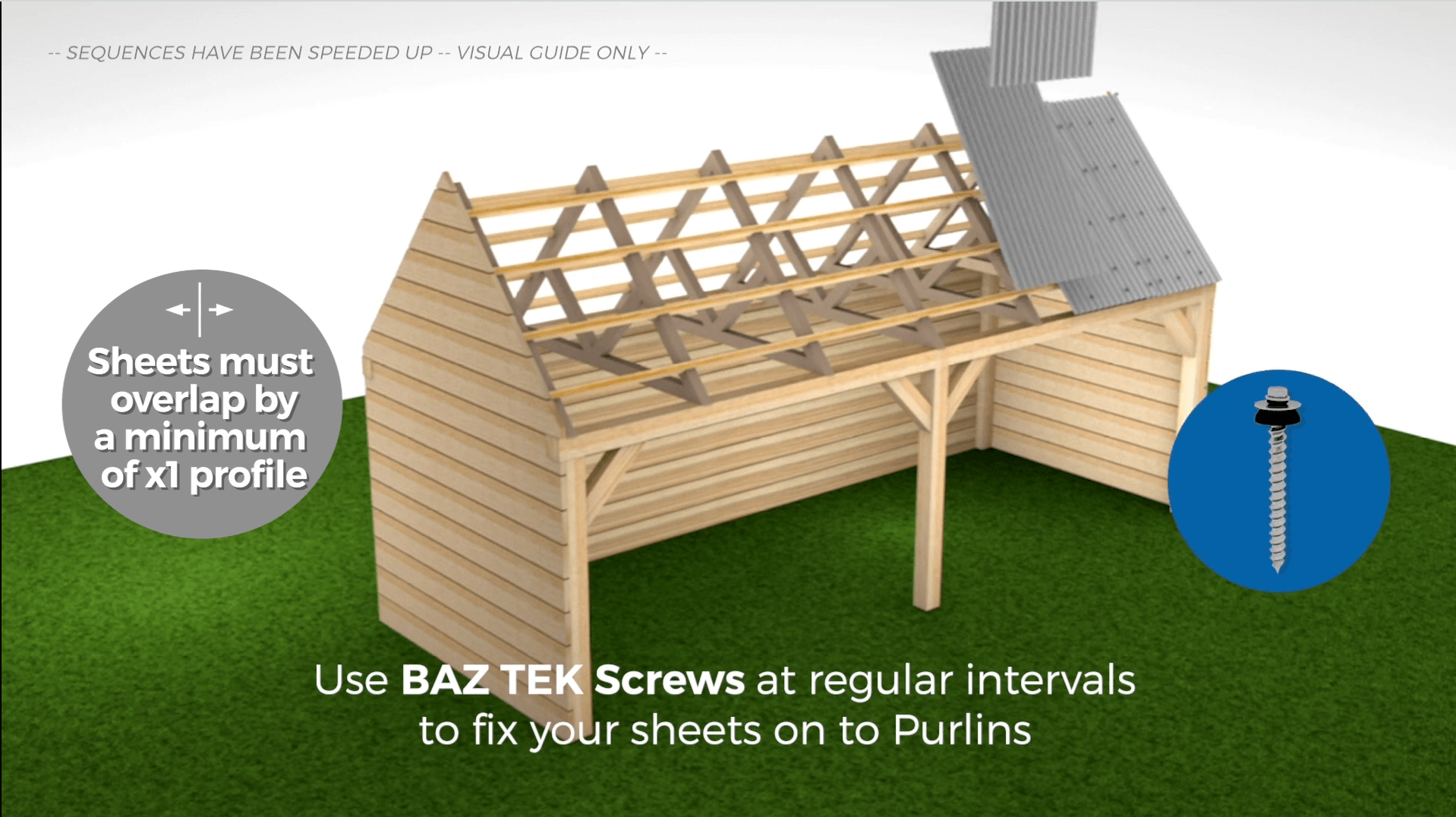

It is advised to lay the first few sheets but not to fix them down until you have ensured they are all correctly aligned with the purlins and each other. Installing in this way can ensure you do not have to re-fit any sheeting durling the installation or after.

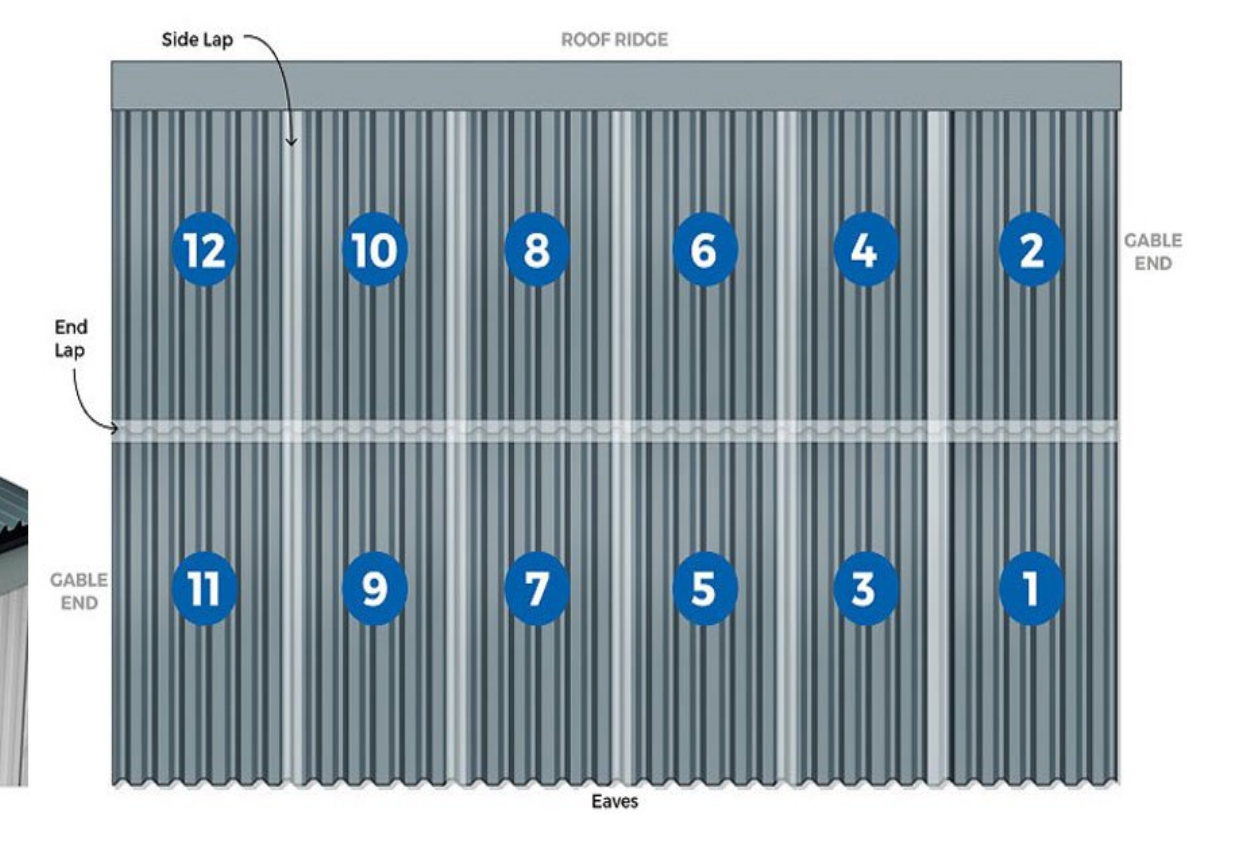

When installing a double sheet run, it’s advised to follow the image:

How to lay Cladco Roof Sheets in Box Profile

When installing a roof that is single pitch it’s advisable to have a minimum pitch of 4-5°, ideally, the pitch will be higher than this to ensure adequate water run off. As above, you should start with the eaves and choose the corner furthest away from prevailing wind direction (as before this can prevent water ingress and wind from penetrating).

If you find that the first sheet has not been installed perpendicular to the ridge and eaves you may need to make adjustments regularly throughout the installation. You may experience a sawtooth effect at the eaves, if the building is uneven or is not square this may be something you cannot avoid.

It’s important to allow the sheets to extend beyond the bottom purlin to enable rainwater to effectively drain into the gutters below or fall beyond the below wall.

Cladco Roofing sheets should overlap by one corrugation when installed side by side, missing this step may cause water ingress into the building below. The overlaps are recommended to have mastic tape lapping down the sheeting.

Cladco Tile Form Sheeting - How To Lay Sheets on a roof

Single Pitch Tile Form roofing projects should have a minimum degree of pitch of 12, it’s imperative to lay tile form sheeting from right to left. The first sheet put onto the roof purlins should be installed in the correct place and secured, screws should line up with purlins below. The fixings should be installed just beneath the tile form drop (Which is the curved aspect of the tile form sheeting)

The maximum sheet length Cladco can supply is 6m length. Any projects which need a longer length than this will need to be done in a two-sheet run. Two sheet runs should be installed using the same instructions as above.

Cladco Tile form sheets ought to be laid starting from the right to left, each sheet should lap over the next sheet with the small gully aspect on the final lap of the sheet. Tile form sheeting should always overlap by at least one corrugation to create an adequate cover.

Each new tile form sheet should be secured into the correct position before applying the mastic tape and screws. You can use a wood block and heavy object such as a mallet with a piece of soft material between the wood and sheet to avoid any potential scratches or damage to the sheets coating.

Instructions on how to lay Cladco Corrugated Roofing Sheets

When creating a single pitch roof out of corrugated sheeting the minimum pitch advised is 10°. When installing a single sheet project start with the eaves and begin with the corner furthest away from prevailing wind. Installing in this way will prevent water ingress and ensure a weatherproof seal. If the building is not square you may end up with an effect known as sawtooth, this may not be avoidable.

The initial first row of corrugated sheets should extend well over the purlin below and eaves, this will enable rainwater to drain into the gutter and fall well away from the wall.

Corrugated sheeting should always overlap by a minimum of one corrugation, this can be known as side laps. When overlapping corrugated sheeting its advised you use cladco lapping tape.

For maximum sheet lengths in corrugated, we can supply 5m in a 0.5mm thickness and up to 7m length in the 0.7mm thickness. For projects which require a longer length, you will need to create a two- sheet run.